Welcome to our company!

◉ Available Products

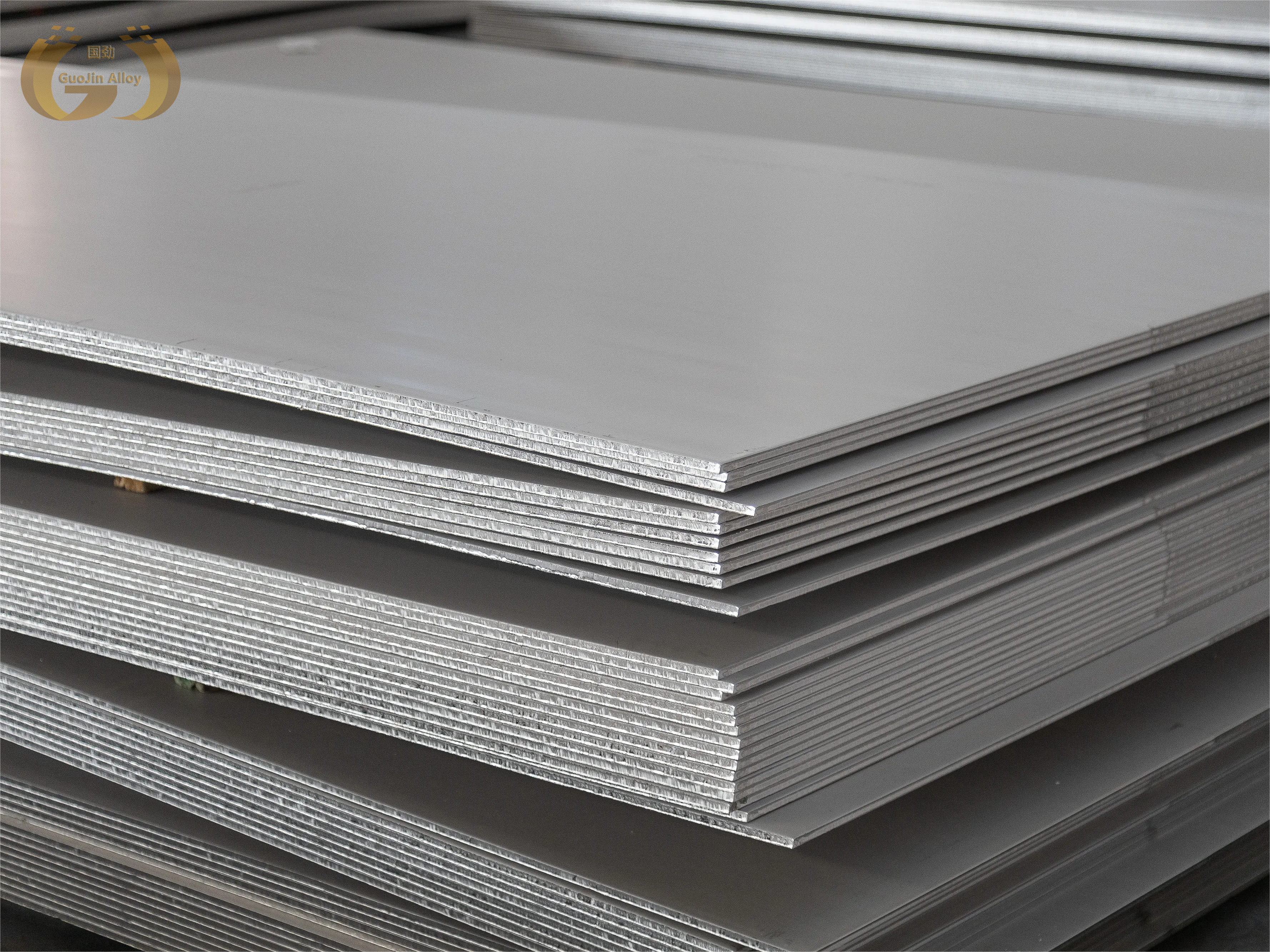

Plate/Sheet

Bar/Rod

Pipe/Tube

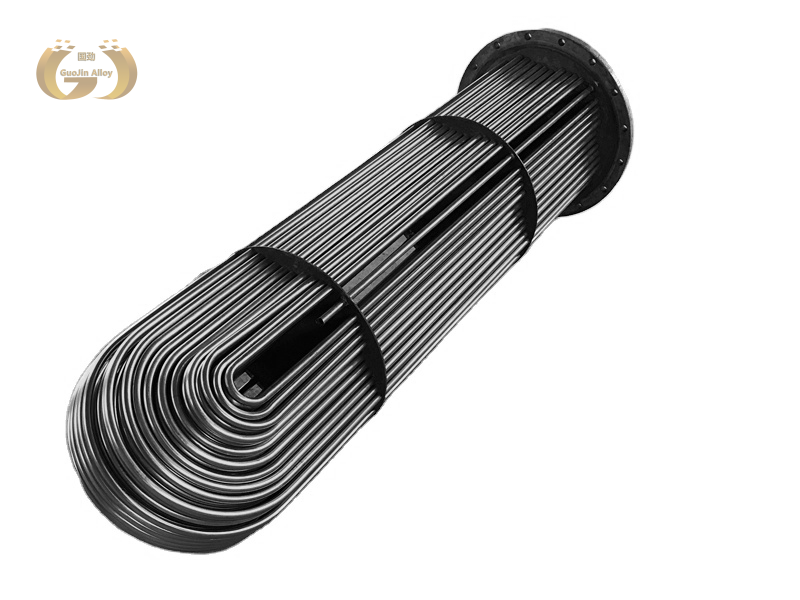

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

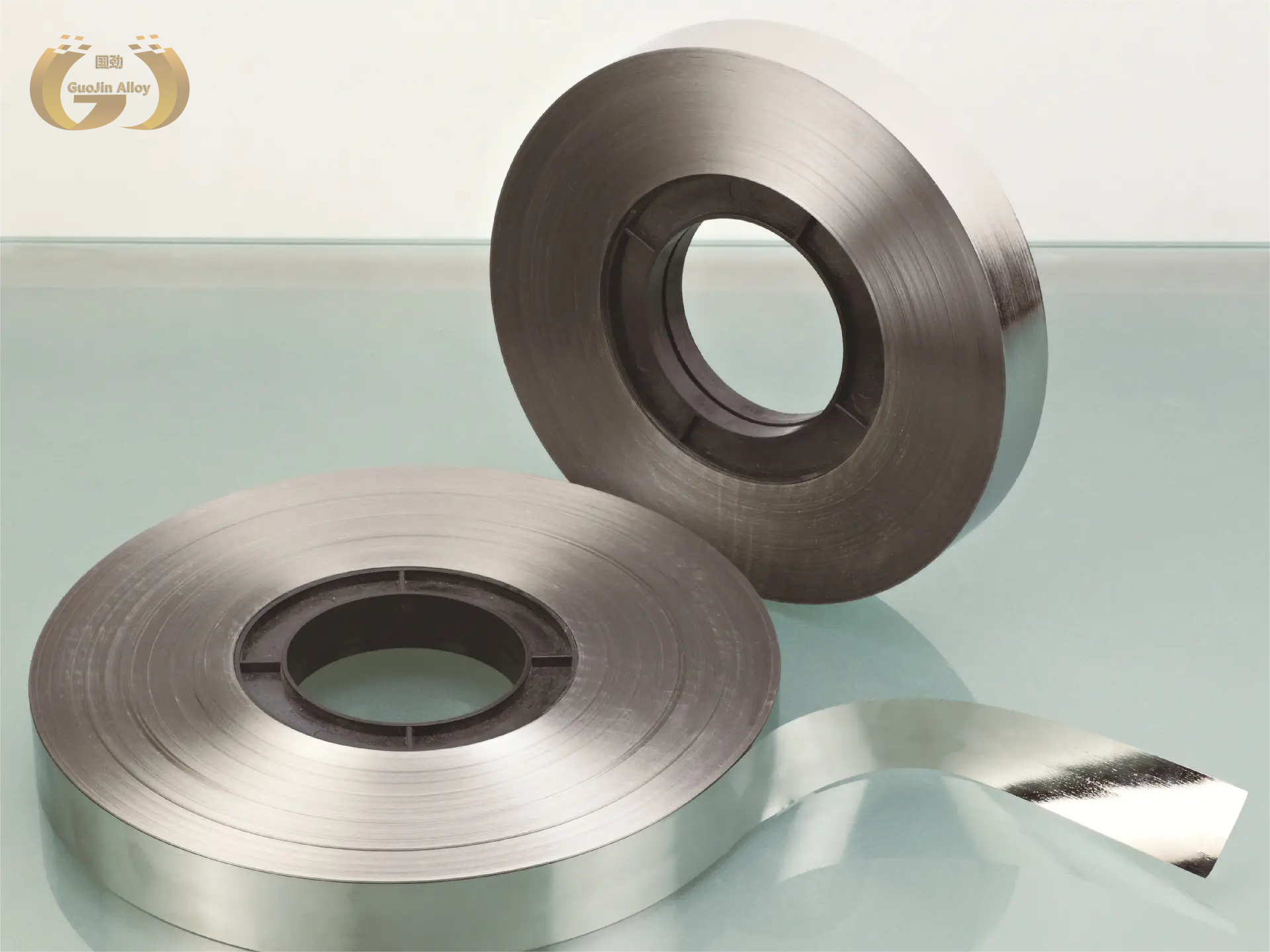

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

316Ti material properties

316Ti is a titanium-stabilized version of Type 316 stainless steel, known for its superior corrosion resistance in aggressive environments. This alloy offers excellent resistance to corrosion, pitting, and crevice corrosion in chloride-containing environments, making it ideal for applications in chemical processing, marine environments, and pharmaceutical industries. The addition of titanium enhances the alloy's resistance to sensitization during welding or exposure to elevated temperatures, ensuring long-term durability and performance. 316Ti is also well-suited for use in high-temperature applications due to its good mechanical properties and oxidation resistance at elevated temperatures. Overall, its versatility, durability, and corrosion resistance make it a popular choice for a wide range of industrial and commercial applications.

Advantage

1. Superior corrosion resistance in aggressive environments for long-term durability.

2. Excellent resistance to pitting and crevice corrosion in chloride-containing environments.

3. Enhanced resistance to sensitization during welding or high-temperature exposure.

4. Versatile for use in chemical processing, marine, and pharmaceutical industries.

5. Good mechanical properties and oxidation resistance at elevated temperatures.

6. Titanium stabilization ensures consistent performance and extended service life.

7. Suitable for high-temperature applications due to its robust mechanical properties.

8. Widely used in various industrial and commercial applications for its reliability.

316Ti Material application areas

316Ti stainless steel finds widespread use across diverse industries due to its exceptional corrosion resistance and mechanical properties. It is extensively applied in chemical processing plants for reactors and pipelines, marine environments for boat fittings, pharmaceutical manufacturing for equipment, and food processing for its non-reactivity. In automotive and architectural sectors, it's used for exhaust systems and structural components due to its durability and aesthetic appeal. Moreover, its resistance to corrosion in harsh petrochemical environments and biocompatibility in medical devices further highlight its versatility and reliability across various applications.

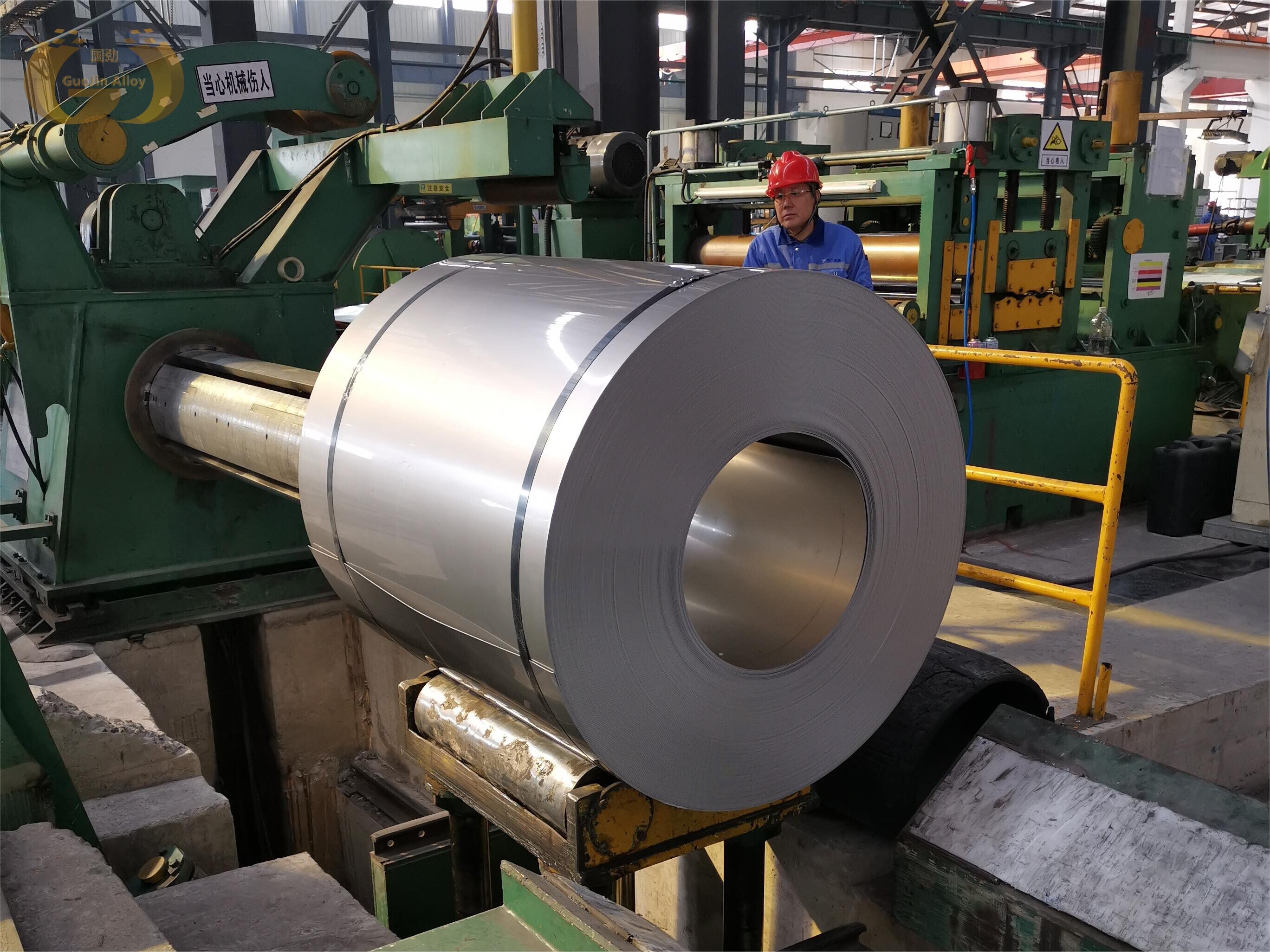

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.