Welcome to our company!

Equivalent grade:

● ASTM A297/297M-14 Grade HX

◉ Available Products

● Furnace door

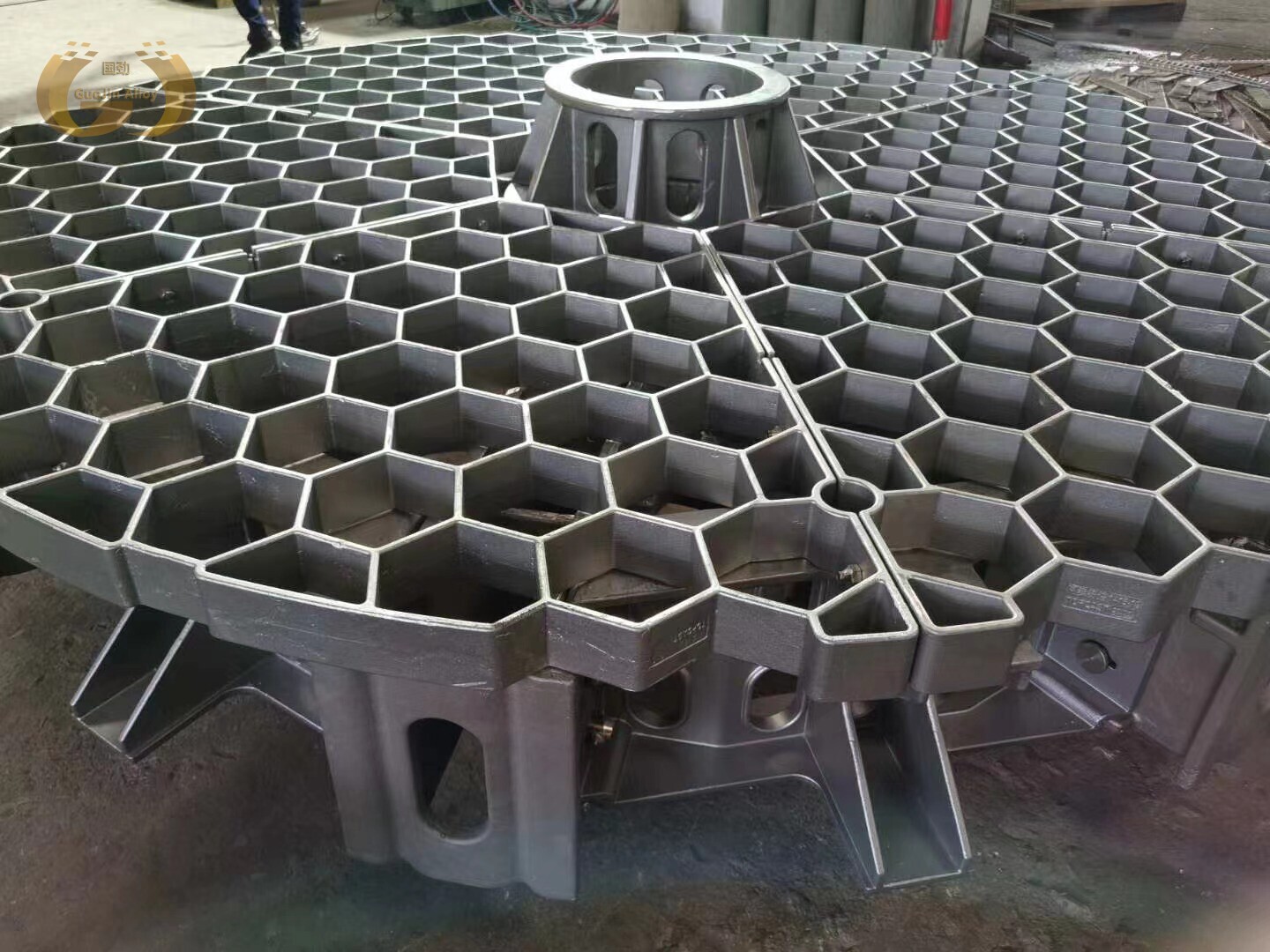

● Heat-resistant furnace bottom plate

● Heat-resistant guard plate

● Precision cast heat-resistant frames and trays

● Heat-resistant heat treatment tooling and fixtures

● Cement drying kiln components

● Ore roasting furnace components

● High-temperature heat radiation tubes

● Heat-resistant heat exchanger tube supports and clamps

● Heat-resistant screws and spirals

● Coal injection nozzles for power plants

● Heat-resistant slide rails

● Heat-resistant U-shaped radiant tubes

● Heat-resistant centrifugal cast tubes

● Heat-resistant cantilever rollers, rollers, roller heads

● Lost wax precision cast heat-resistant sliders

● Heat-resistant steel pusher

● High-temperature thermometer casings

● Kiln mouth and kiln tail protection plates

● Aluminum factory-specific heat-resistant grapples, aluminum slag grapples

● Cement factory high-temperature grinding drums

● Wind caps for power plants

● Incinerator grate bars

● Heat treatment support rods

● Walking beam furnace heat-resistant cantilever rollers

● Heat-resistant rolling mill rolls

● High-temperature hot press molds

● Steel mill heat-resistant furnace covers

● Heat-resistant mesh belt furnace bottom plates

◉ Product Details

Chemical composition

Physical properties

Material properties

UNS N06006 is a high nickel-chromium iron alloy known for exceptional high-temperature strength and oxidation resistance. This material, classified under ASTM A297, is engineered for performance in extreme temperature environments, offering outstanding resistance to corrosion and thermal fatigue. Its robust composition provides excellent mechanical properties at elevated temperatures, making it ideal for demanding industrial applications.

Advantage

- Superior oxidation resistance in high-temperature environments.

- Maintains mechanical integrity under thermal stress.

- Highly resistant to corrosion and wear.

- Suitable for high-temperature casting processes.

- Excellent strength-to-weight ratio.

Application

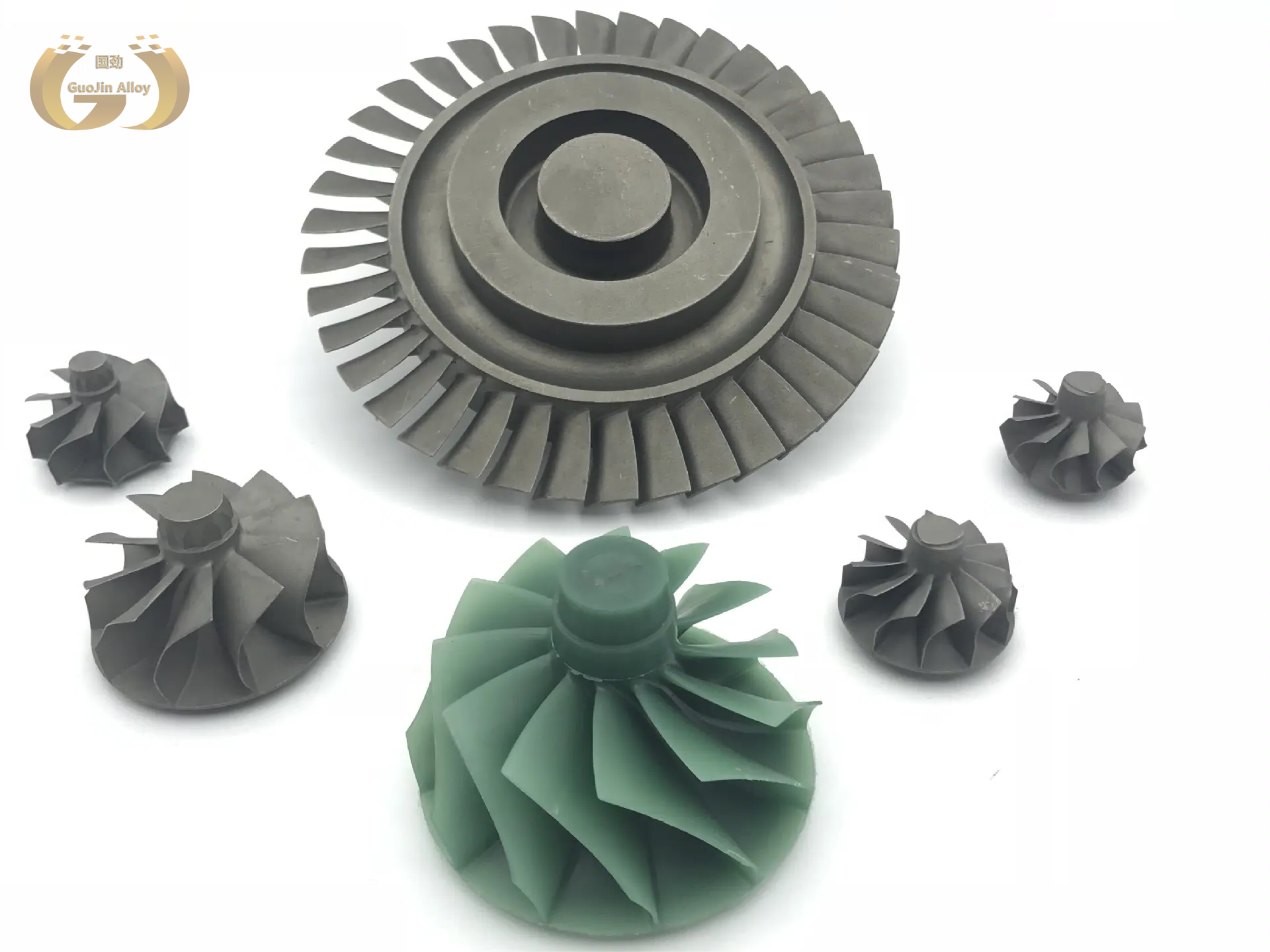

UNS N06006 is predominantly utilized in the aerospace, power generation, and chemical processing industries. It is designed for components such as turbine blades, combustion chambers, and other critical high-temperature parts. The alloy's capability to perform under severe conditions also makes it suitable for use in advanced engineering applications where reliability and performance at high temperatures are crucial.

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.