Welcome to our company!

Equivalent grade:

● Alloy 926

● DIN W. Nr. 1.4529

◉ Available Products

Plate/Sheet

Bar/Rod

Pipe/Tube

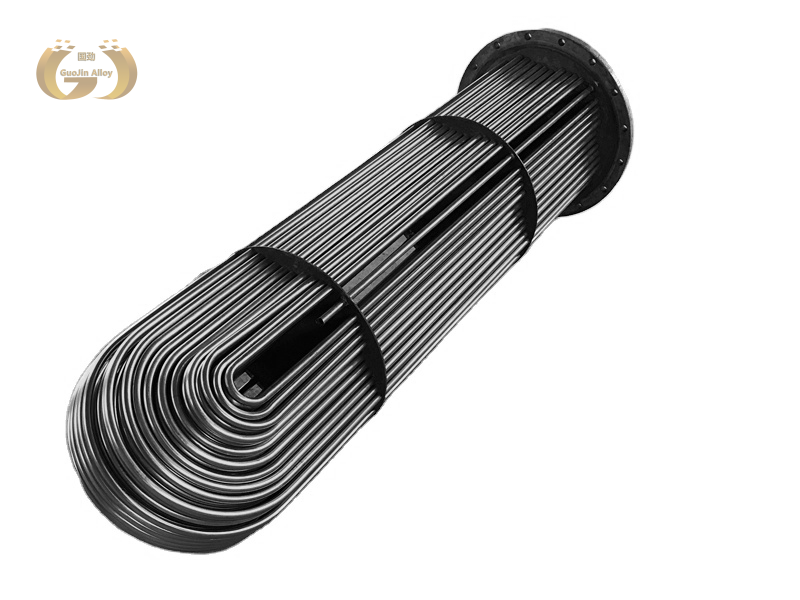

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

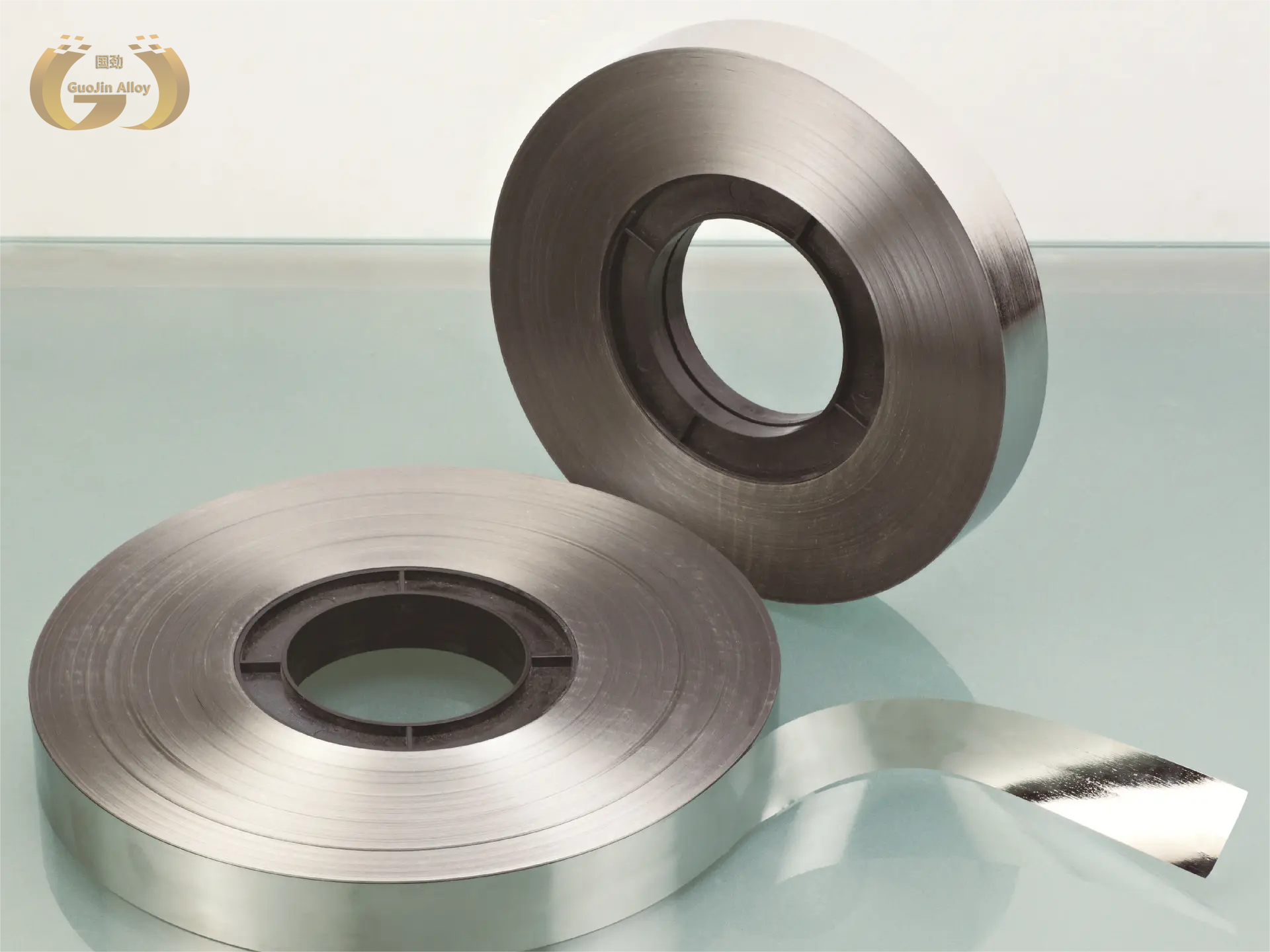

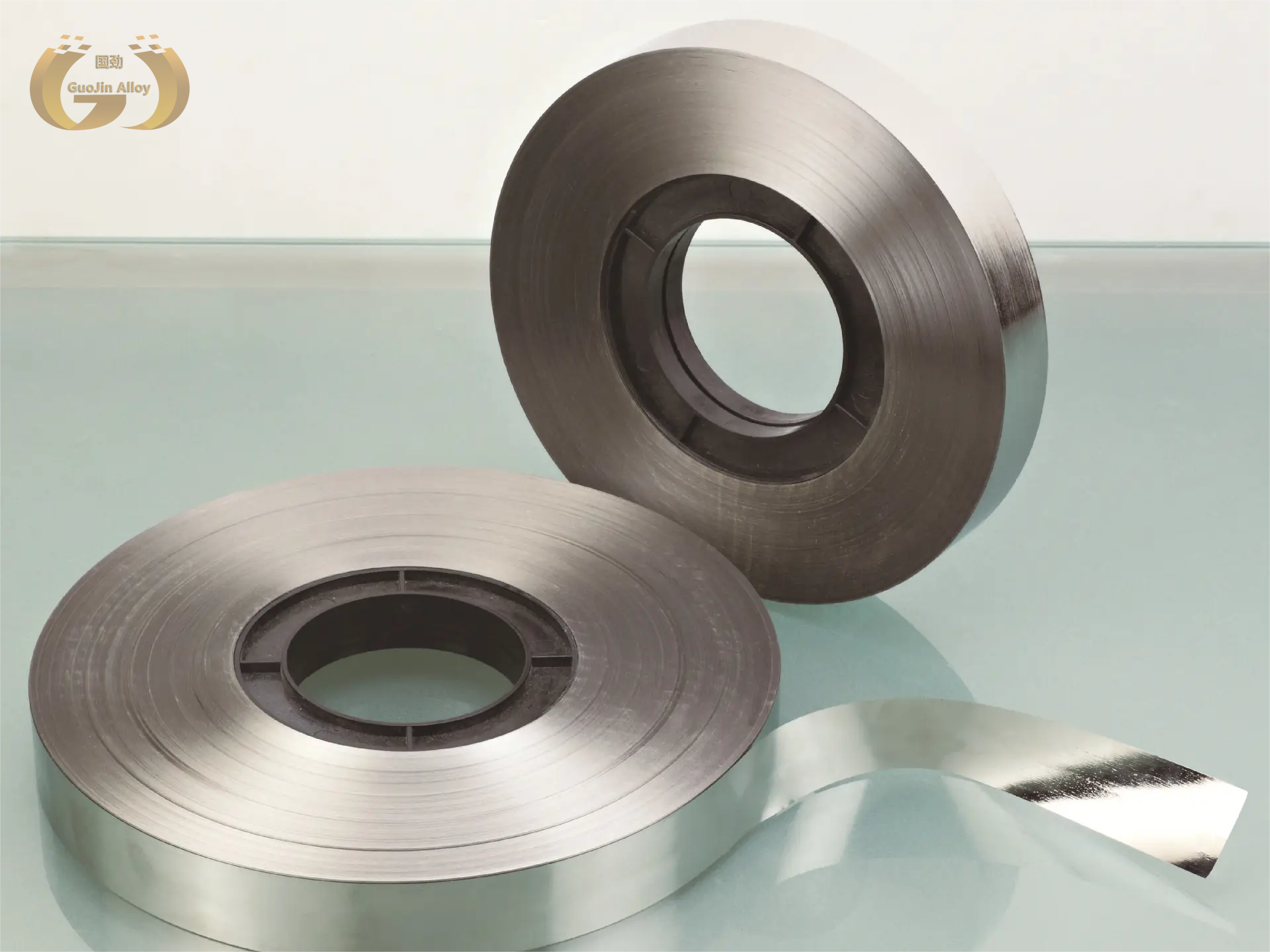

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

Incoloy 926/1.4529 Material Properties

INCOLOY 926 alloy, UNS N08926, W. Nr. 1.4529, or INCOLOY Alloy 25-6MO, stands as a super austenitic stainless steel featuring 6% molybdenum and nitrogen enhancements. Its exceptional corrosion resistance in diverse aqueous and corrosive environments, particularly non-oxidizing acids like sulfuric and phosphoric, sets it apart. With a superior ability to withstand pitting, crevice corrosion, and chloride ion stress corrosion in halide and acidic settings enriched with sulfur and hydrogen, it outperforms traditional austenitic stainless steels like AISI 316 and 317 where they falter.

This alloy's mechanical prowess slightly surpasses 904L, enabling it to fabricate pressure vessels capable of operating within a temperature range of -196°C to 400°C. Its robust resistance to chlorides and other halides makes INCOLOY 926 a prime choice for challenging environments like sea water, brackish water systems, caustic chloride applications, and pulp mill bleaching processes.

As a cost-effective alternative to high-nickel alloys in select marine, chemical processing, and industrial settings, INCOLOY 926 finds widespread use in chemical and food processing facilities, pulp and paper bleaching plants, marine and offshore platforms, salt pan evaporators, air pollution control systems, condensate and water supply pipelines, as well as feedwater heaters in the power industry.

Advantage

1. High corrosion resistance in aggressive chemical environments.

2. Excellent mechanical strength for demanding industrial applications.

3. Superior resistance to pitting and crevice corrosion.

4. Good weldability for ease of fabrication and installation.

5. Enhanced resistance to chloride-induced stress corrosion cracking.

6. Versatile material suitable for various industrial applications.

7. Long-term durability in high-temperature and corrosive conditions.

8. Reliable performance in oil and gas, chemical processing, marine environments.

Incoloy 926/1.4529 material application areas

Flue gas desulfurization units for phosphoric acid production, evaporators, heat exchangers, filters and mixers, sulfuric acid conveying units, condensers, fire suppression systems, seawater filtration systems, hydraulic and supply piping systems in the offshore industry, pulp systems, Salt evaporative condenser, power plant polluted cooling water pipeline system, reverse osmosis seawater desalination device, corrosive chemical transportation storage tank, halogen acid catalytic organic matter production equipment, etc.

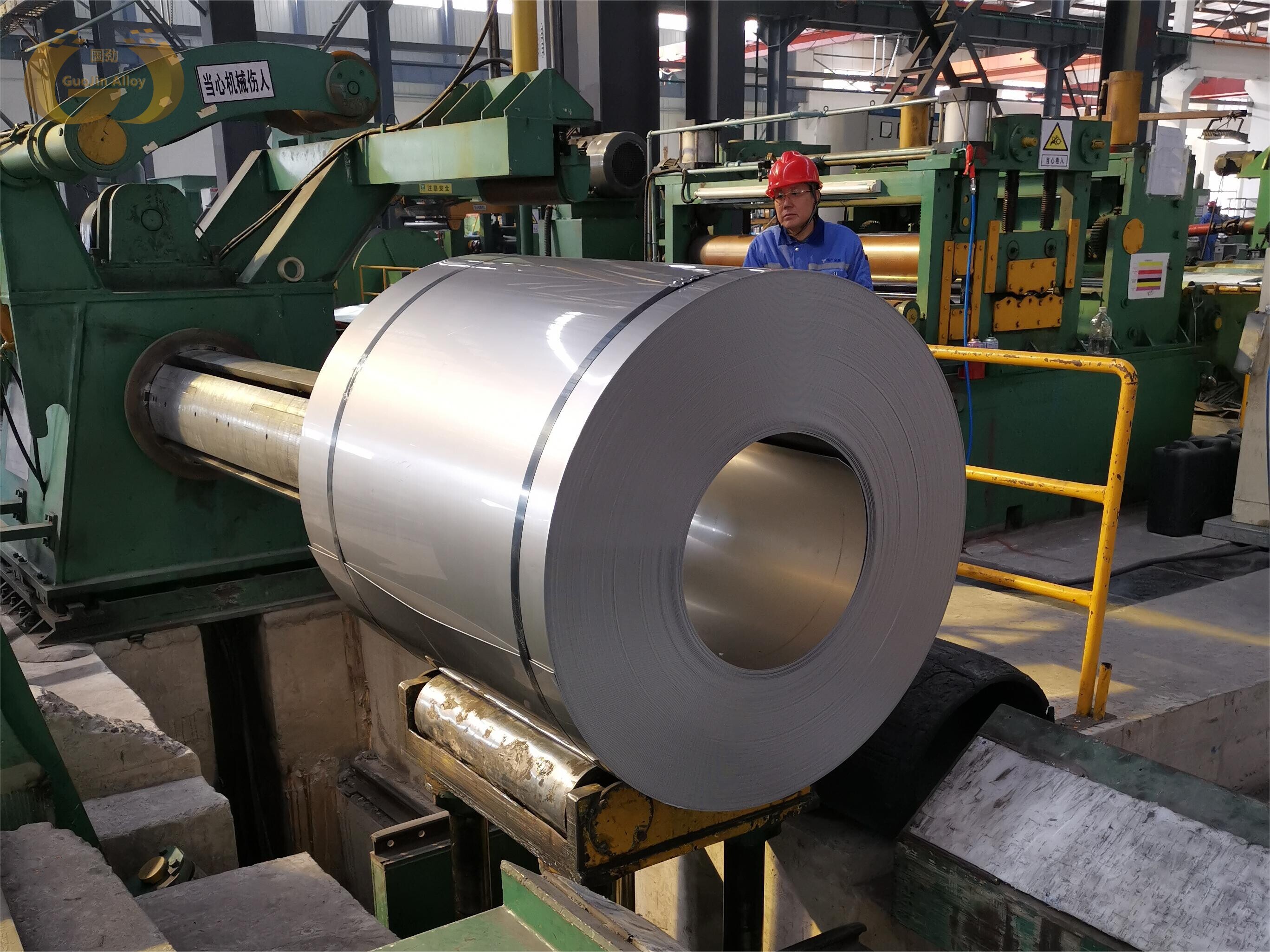

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.