Welcome to our company!

Equivalent grade:

● DIN W. Nr. 1.4545

● EN X5CrNiCuNb15-5

● UNS XM-12

◉ Available Products

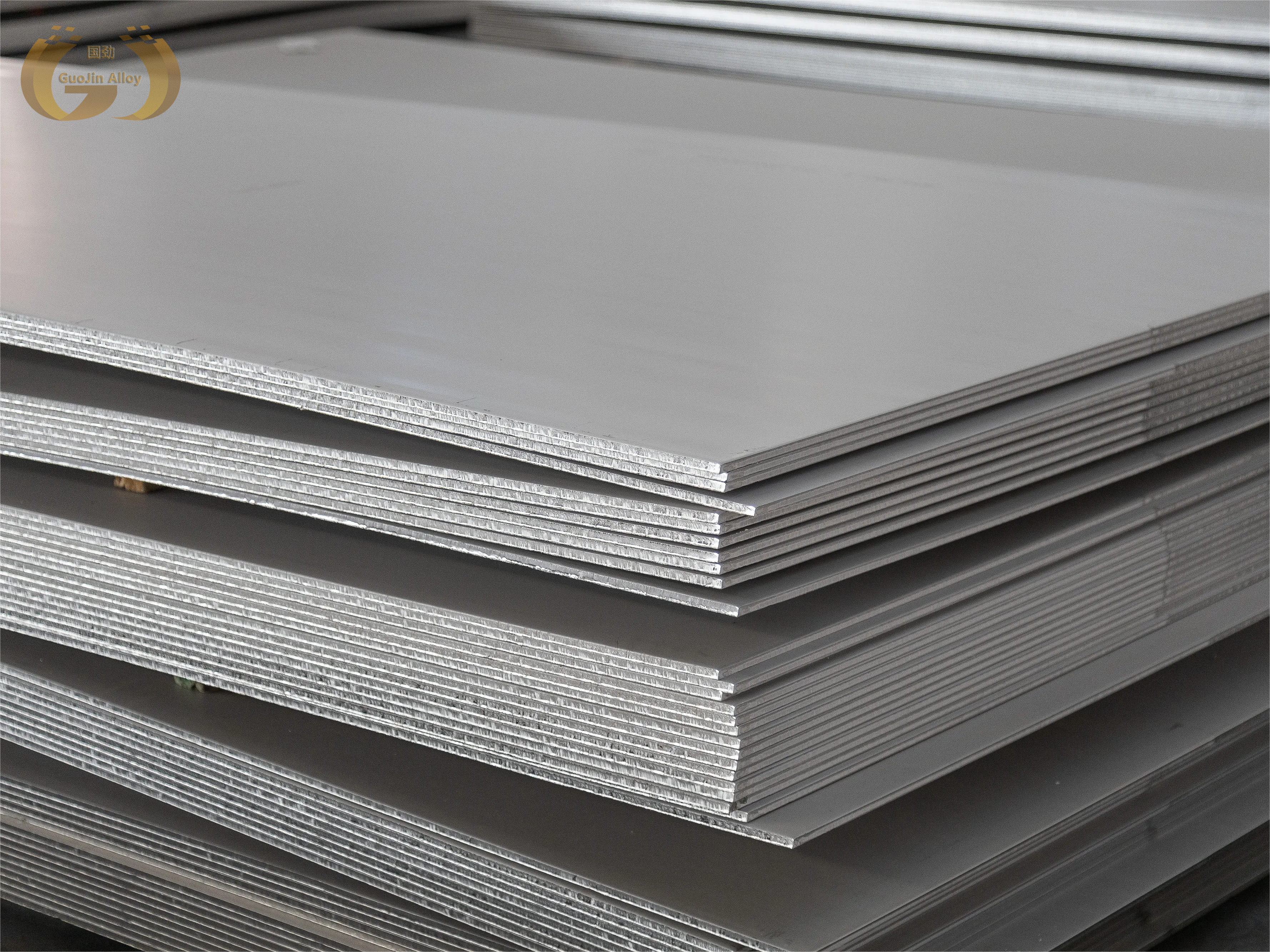

Plate/Sheet

Bar/Rod

Forgings

Pipe/Tube

Rolling

Pipe fittings (Flange,Tee, Elbow,Reducer...)

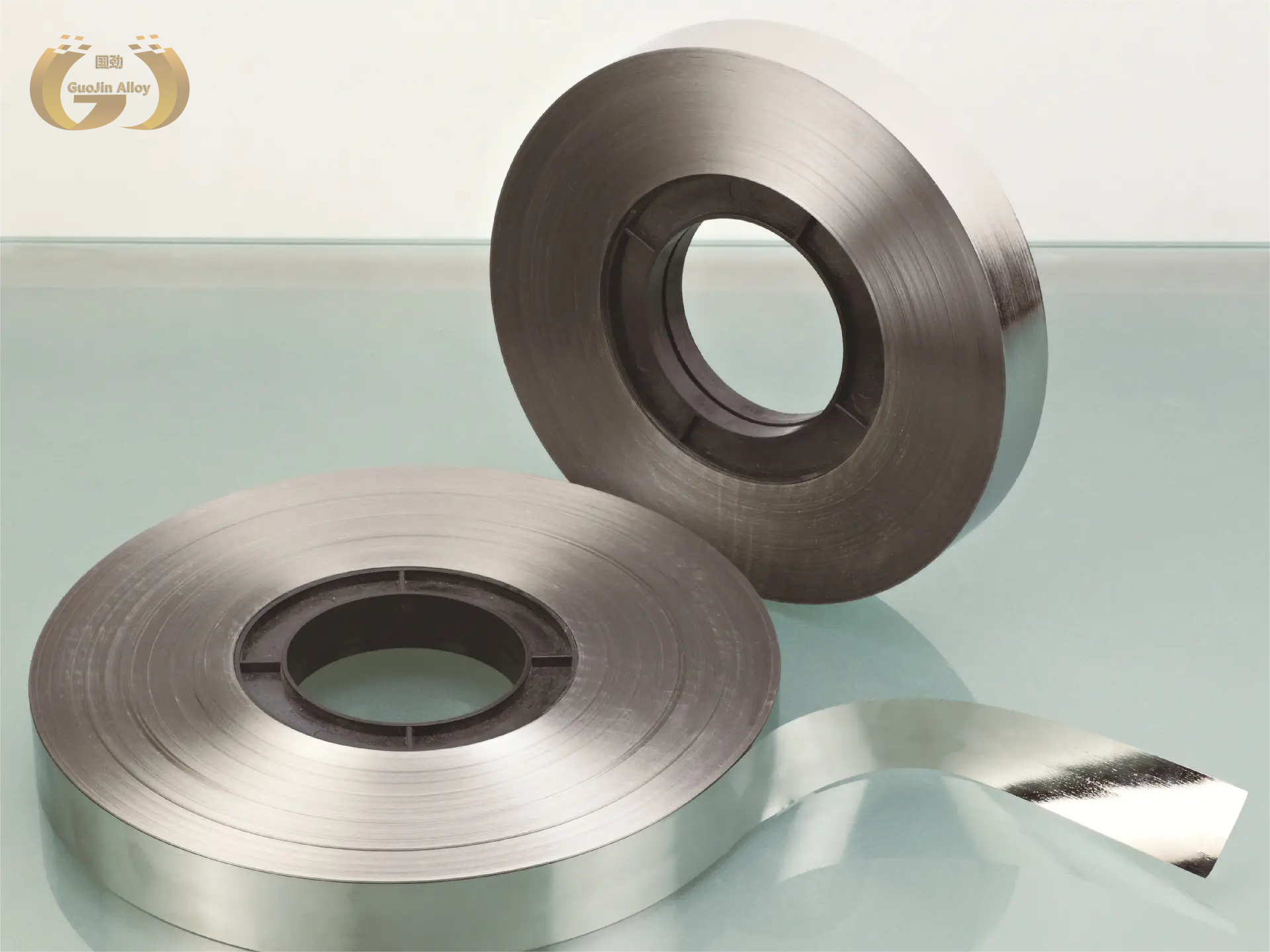

Strip

Fittings

Wire

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

Mechanical properties

15-5PH material properties

15-5PH is a martensitic precipitation hardening stainless steel developed on the basis of 17-4PH. Compared with 17-4PH, 15-5PH has lower chromium and copper content and higher nickel content. Therefore, after heat treatment, it can effectively reduce the probability of ferrite formation and reduce the aggregation caused by excessive dispersion strengthening phase. In addition to high strength, 15-5PH has the advantages of high transverse toughness and good deformation performance. 15-5PH is mainly used in service environments below 300°C that require high strength, good toughness, and good corrosion resistance, such as high-strength forgings, high-pressure system valve components, aircraft engine parts and fasteners.

Advantage

1. High strength and toughness for demanding applications.

2. Excellent corrosion resistance in diverse environments.

3. Good formability and weldability for ease of fabrication.

4. Versatile applicability across industries like aerospace and automotive.

5. Reliable mechanical properties at both room and elevated temperatures.

6. Resistance to stress corrosion cracking and pitting.

7. Cost-effective solution due to its balanced properties.

8. Wide availability in various forms for manufacturing needs.

15-5PH material application areas

15-5PH has a tensile strength of less than 1400Mpa and a hardness of less than 444HB. It is required to be resistant to oxidation and weak acid, alkali and salt corrosion environments. It is recommended to use 15-5PH. 15-5PH can replace 17-4PH and various traditional alloy steels and stainless steels.

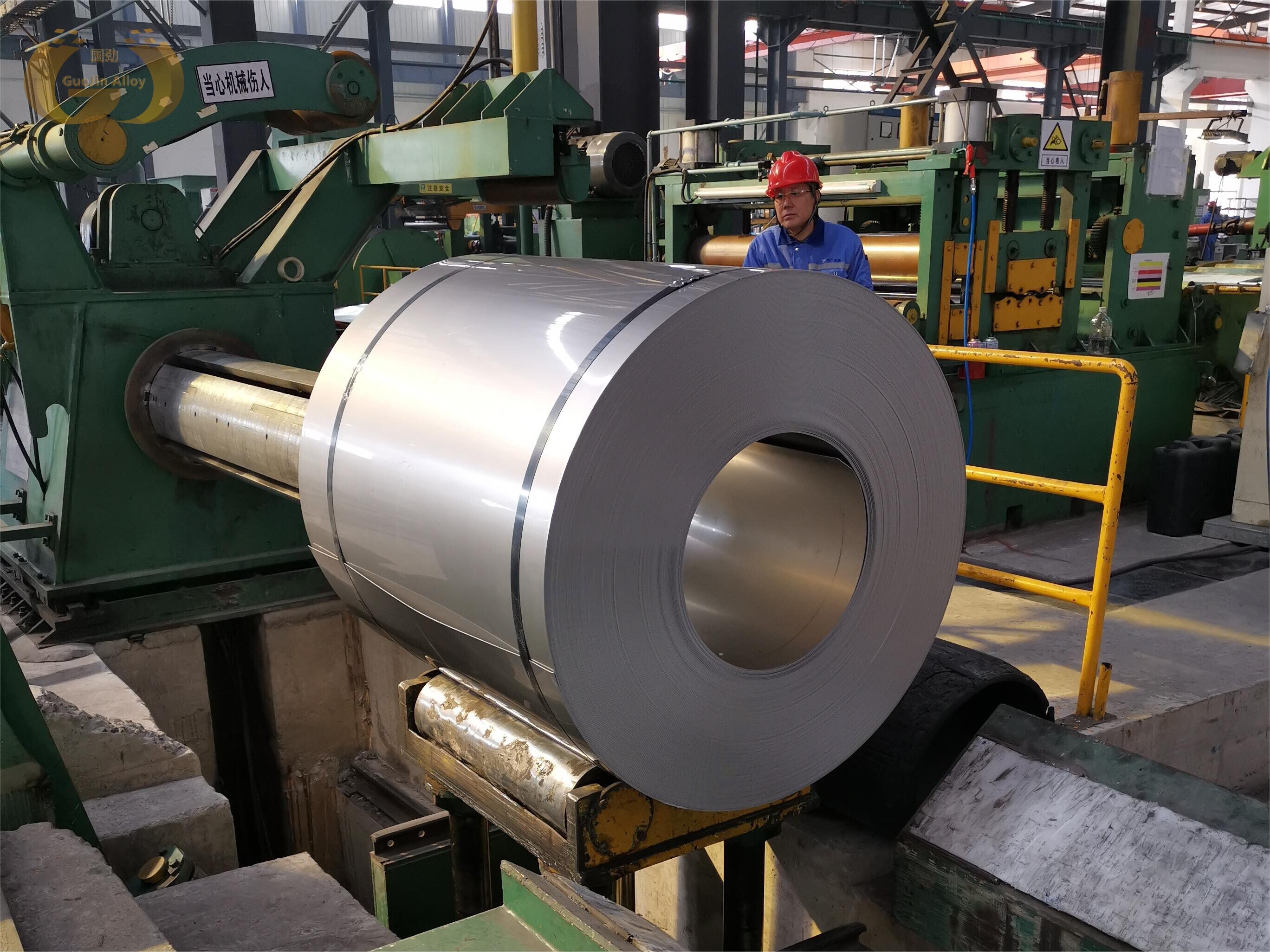

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.