Welcome to our company!

Equivalent grade:

● DIN W. Nr. 2.4675

● EN 2.4675

◉ Available Products

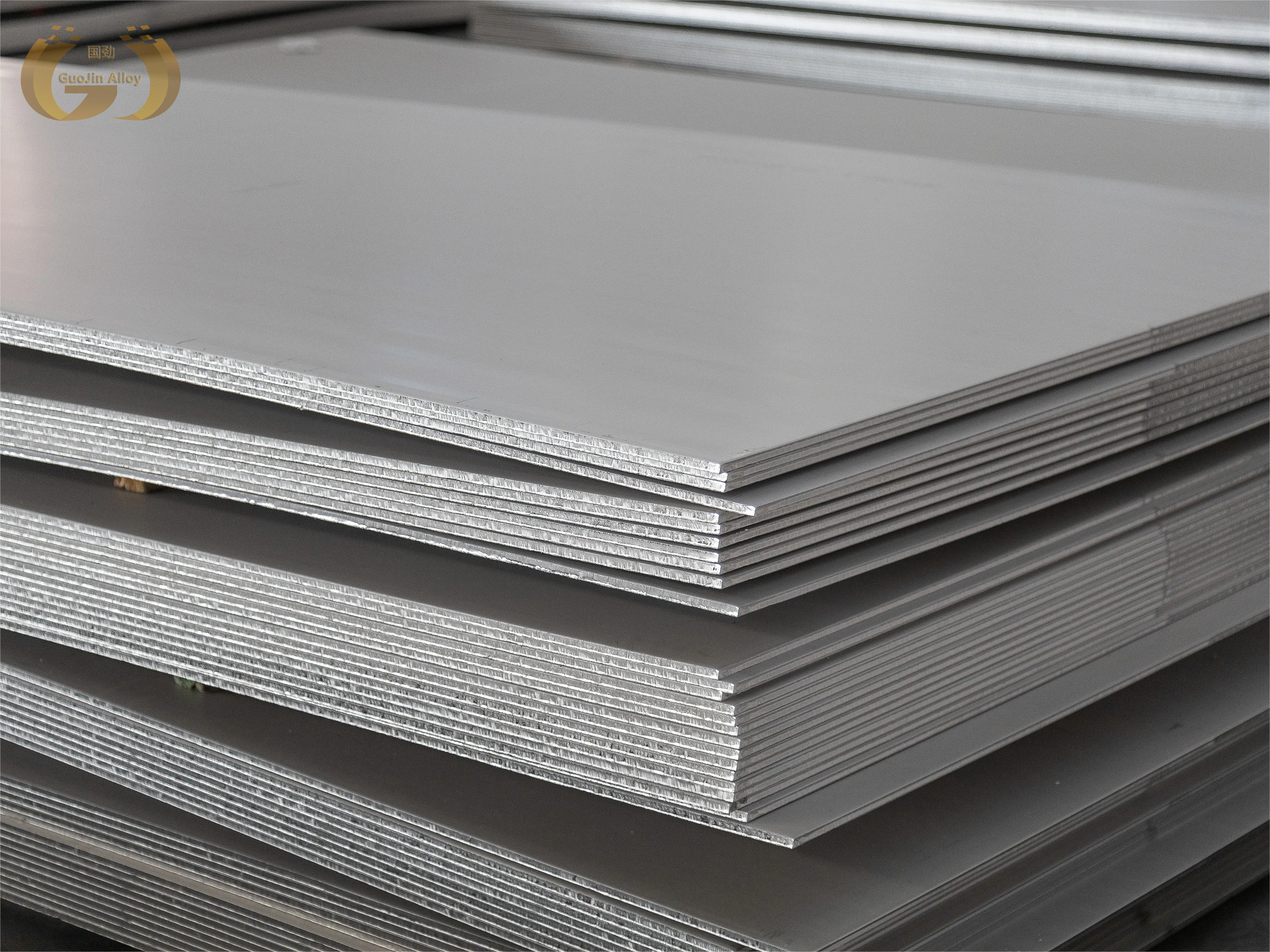

Plate/Sheet

Bar/Rod

Pipe/Tube

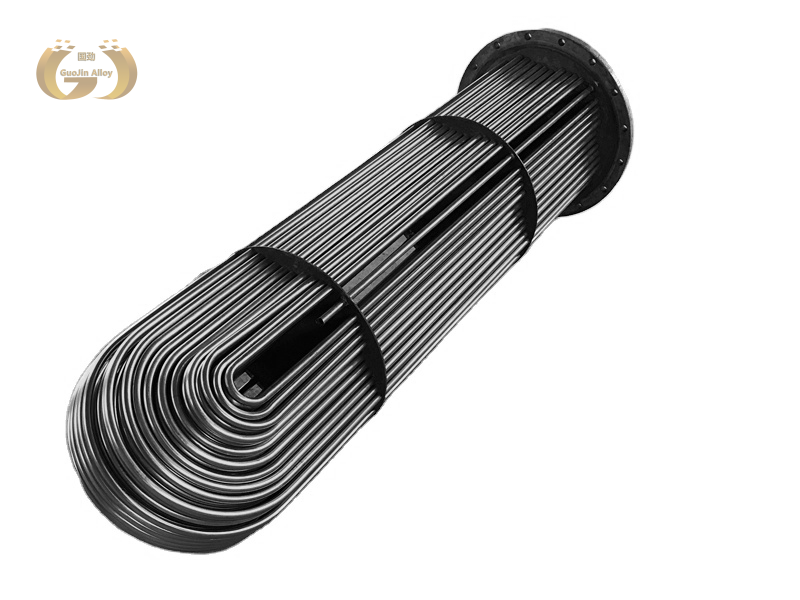

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

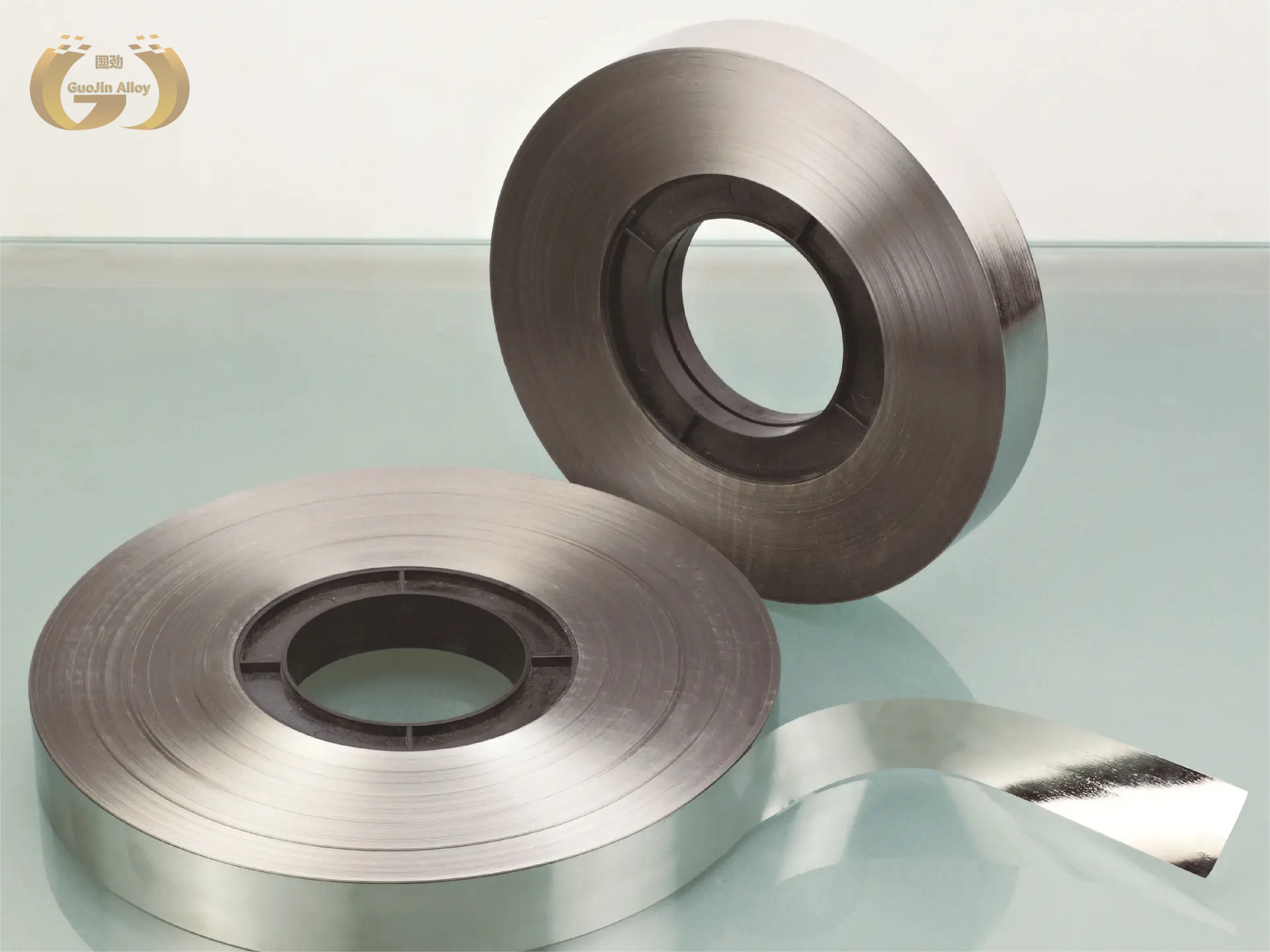

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

Introduction

Hastelloy C-2000 is a versatile corrosion resistant alloy with excellent uniform corrosion resistance in both oxidizing and reducing environments. Resistant to pitting corrosion, crevice corrosion and stress corrosion cracking over a wide temperature range, especially hydrochloric, sulfuric and hydrofluoric acids, as well as chloride and halide solutions.Unlike the previous optimized Ni-Cr-Mo alloys that are only resistant to oxidizing or reducing acids, Hastelloy C-2000 alloy is resistant to both environments. The combined action of molybdenum and copper (at the 16% and 1.6% levels, respectively) gives the alloy excellent resistance to corrosion in reducing media, while high chromium content (23%wt) ensures resistance to corrosion in oxidizing media . From an engineering perspective, the Hastelloy C-2000 offers great potential to increase production. When used in place of the original Ni-Cr-Mo alloy, its enhanced corrosion resistance can obtain longer equipment life under the same material thickness, and can also obtain a higher safety factor under harsher conditions. The improvement in corrosion resistance in all aspects allows the equipment to be used for multiple purposes (reactors, heat exchangers, valves, pumps, etc.), resulting in a greater return on investment. For example, one reactor can be adapted to a hydrochloric acid mixture and then converted to a nitric acid-based mixture in another condition. Due to the various abilities of HastelloyC-2000, it is the best nickel-based alloy material that can adapt to a variety of processes.

Advantages of Hastelloy C-2000

1. Exceptional resistance to a wide range of corrosive environments, including oxidizing and reducing conditions.

2. Superior resistance to pitting, crevice corrosion, and stress corrosion cracking.

3. High resistance to sulfuric acid, hydrochloric acid, and other aggressive chemicals.

4. Excellent weldability and fabrication characteristics for ease of manufacturing.

5. Versatile material suitable for various chemical processing applications.

6. High temperature stability, maintaining integrity at elevated temperatures.

7. Low risk of sensitization, ensuring long-term reliability in corrosive environments.

8. Wide availability and proven track record in critical industries.

Hastelloy C-2000 Application field

Reactors, heat exchangers, towers, pipes in the chemical industry, reactors and dryers in the pharmaceutical industry, components of flue gas desulfurization systems

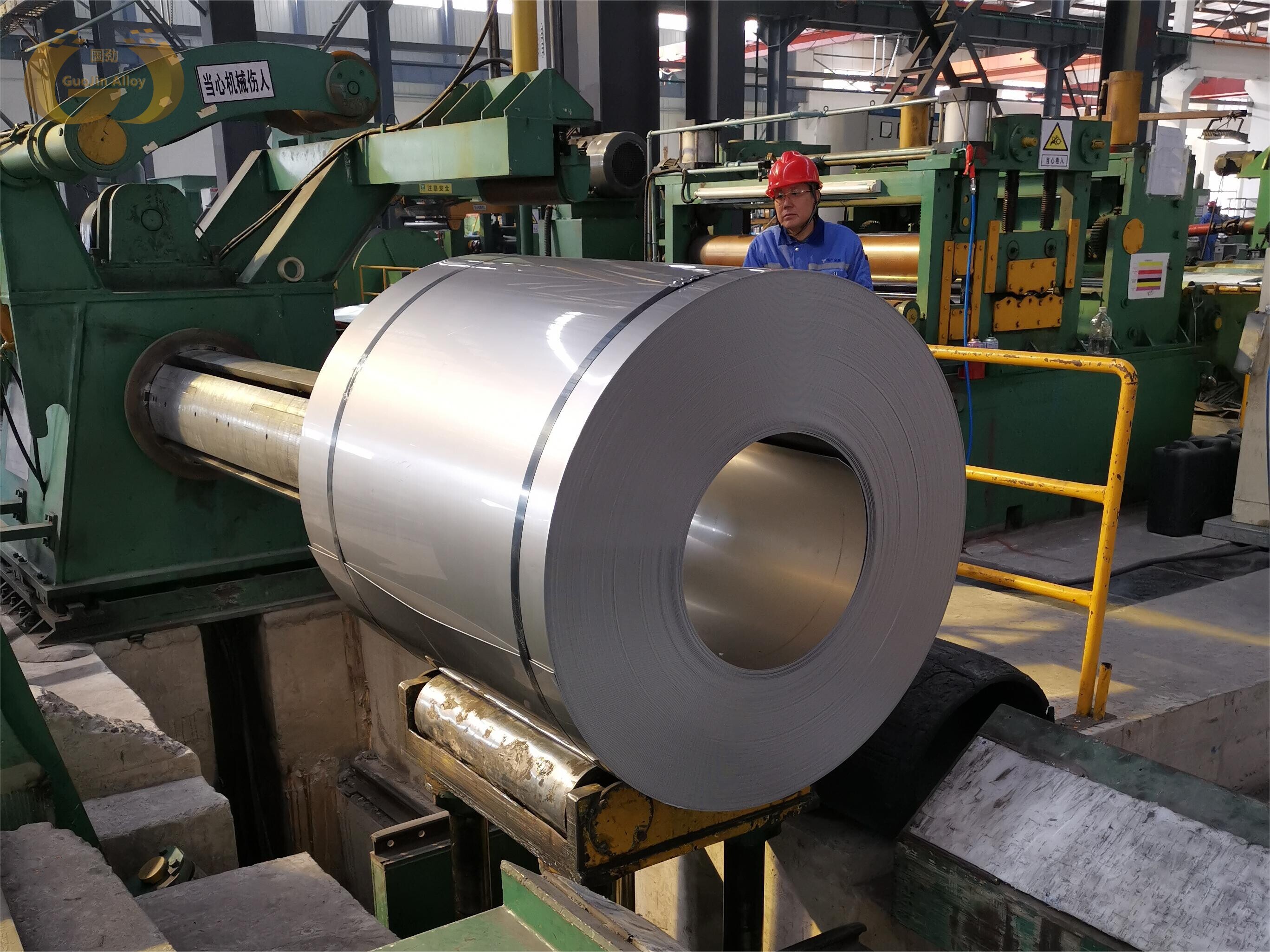

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.