Welcome to our company!

Equivalent grade:

● UNS N07713

● W. Nr. 2.4670

◉ Available Products

Castings

Round bar/rod

◉ Product Details

Chemical composition

Physical properties

Inconel 713C Features

Inconel 713C is a nickel-based superalloy known for its excellent oxidation resistance and high-temperature strength, maintaining stability under high stress and elevated temperatures. Key features include good creep resistance, high tensile and yield strength, and superior corrosion resistance. These properties make it ideal for use in aerospace engines, gas turbines, and other applications requiring long-term durability at high temperatures. Inconel 713C's low elongation is suitable for components that demand high strength with minimal deformation.

1. Excellent high-temperature strength and stability.

2. Superior oxidation and corrosion resistance.

3. Good creep resistance under high stress.

4. Suitable for aerospace and gas turbine applications.

5. Maintains properties in extreme environments.

6. Low elongation for minimal deformation.

7. Reliable performance in long-term high-temperature use.

8. Versatile for various high-stress applications.

Inconel 713C is widely used in high-temperature, high-stress applications due to its excellent oxidation resistance and mechanical properties. Key application areas include aerospace engines, where it is used for turbine blades and other critical components; gas turbines, particularly in hot sections; and industrial furnaces. Its ability to maintain strength and stability at elevated temperatures makes it suitable for components exposed to extreme thermal and mechanical conditions. Additionally, it is used in the chemical processing industry for parts that must withstand corrosive environments at high temperatures.

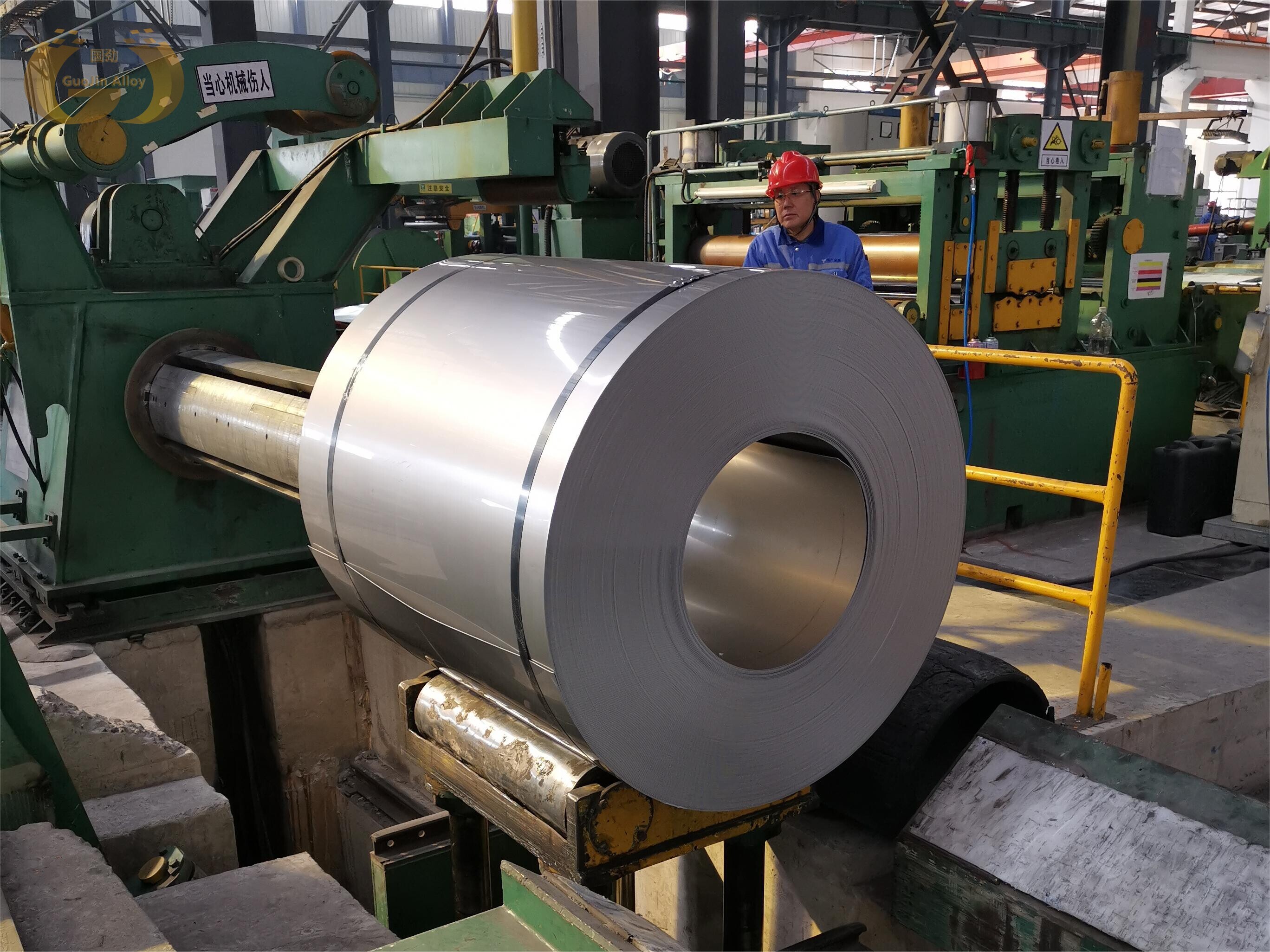

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.