Welcome to our company!

Equivalent grade:

● ASTM A297/297M-14 Grade HN

◉ Available Products

● Furnace door

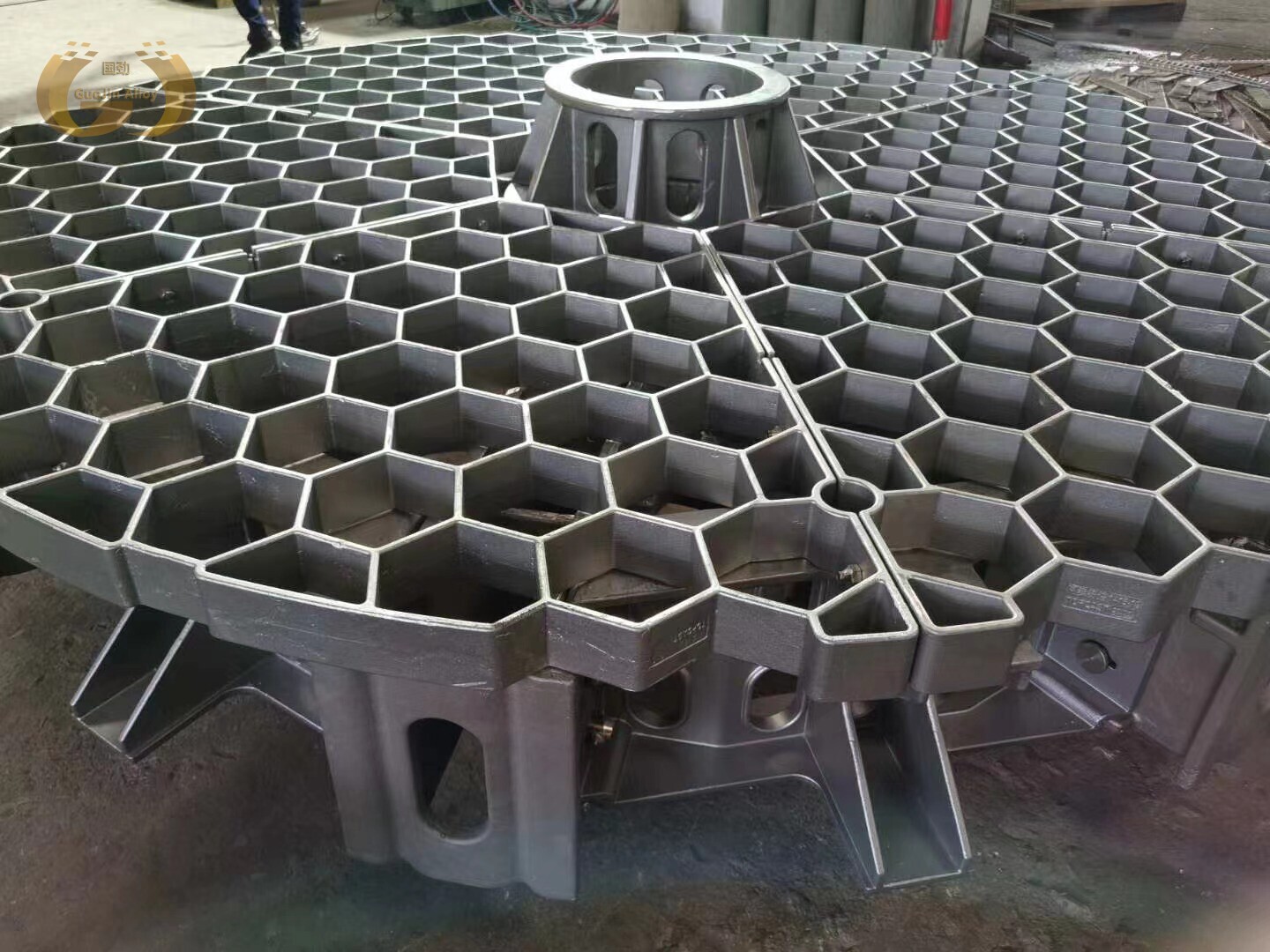

● Heat-resistant furnace bottom plate

● Heat-resistant guard plate

● Precision cast heat-resistant frames and trays

● Heat-resistant heat treatment tooling and fixtures

● Cement drying kiln components

● Ore roasting furnace components

● High-temperature heat radiation tubes

● Heat-resistant heat exchanger tube supports and clamps

● Heat-resistant screws and spirals

● Coal injection nozzles for power plants

● Heat-resistant slide rails

● Heat-resistant U-shaped radiant tubes

● Heat-resistant centrifugal cast tubes

● Heat-resistant cantilever rollers, rollers, roller heads

● Lost wax precision cast heat-resistant sliders

● Heat-resistant steel pusher

● High-temperature thermometer casings

● Kiln mouth and kiln tail protection plates

● Aluminum factory-specific heat-resistant grapples, aluminum slag grapples

● Cement factory high-temperature grinding drums

● Wind caps for power plants

● Incinerator grate bars

● Heat treatment support rods

● Walking beam furnace heat-resistant cantilever rollers

● Heat-resistant rolling mill rolls

● High-temperature hot press molds

● Steel mill heat-resistant furnace covers

● Heat-resistant mesh belt furnace bottom plates

◉ Product Details

Chemical composition

Physical properties

Material properties

UNS J94213, classified under ASTM A297 HN as a high chromium-nickel austenitic stainless steel, is designed for casting applications requiring excellent resistance to oxidation and corrosion at elevated temperatures. Known commonly as 20Cr-25Ni, this alloy offers superior performance in environments subject to high temperatures and corrosive elements, making it ideal for heavy-duty industrial applications.

Advantage

- Outstanding high-temperature corrosion resistance.

- Superior oxidation resistance at elevated temperatures.

- Maintains structural integrity under thermal stress.

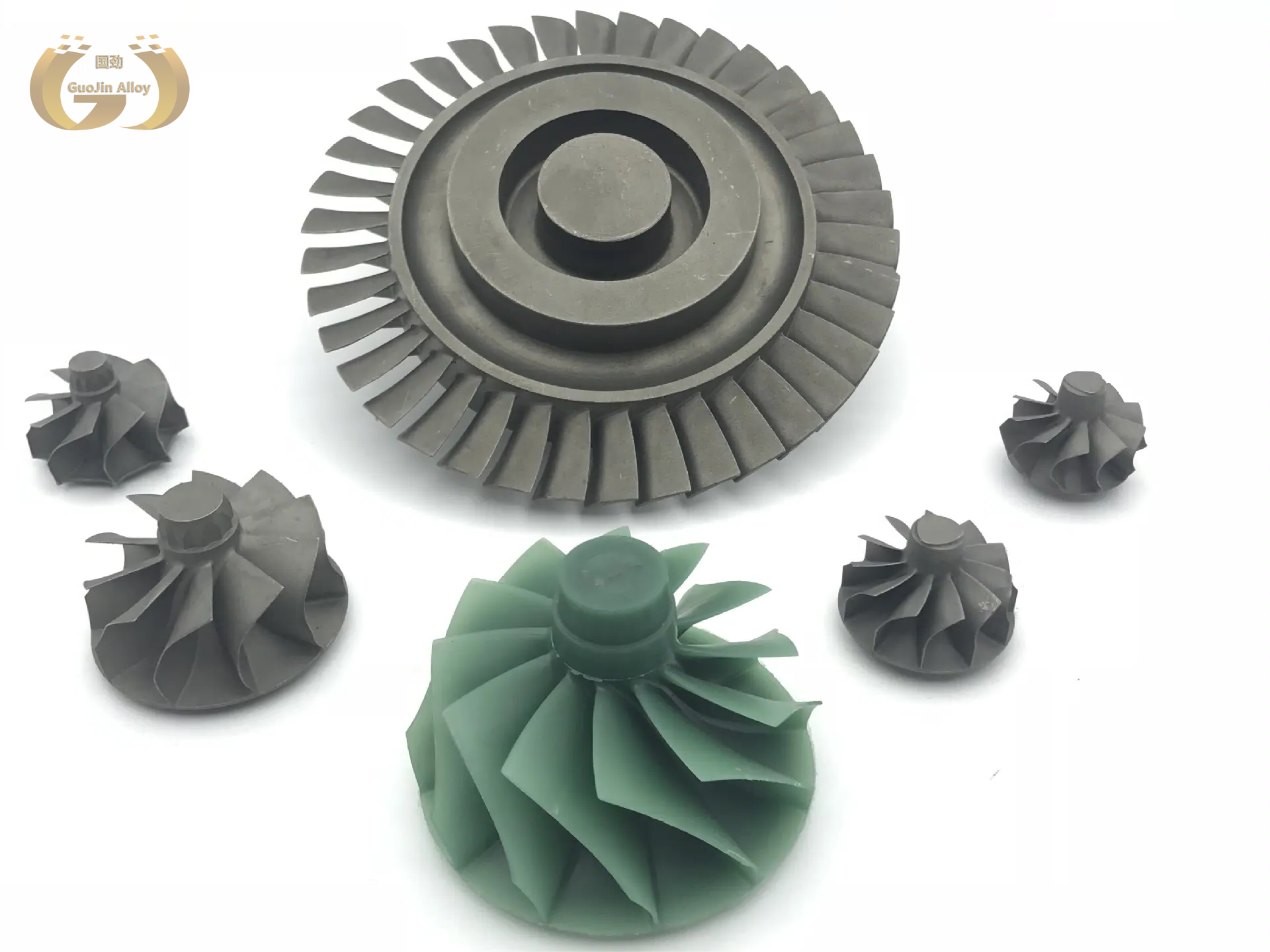

- Excellent for casting complex geometries.

- Durable in fluctuating temperature conditions.

Application

UNS J94213 is primarily utilized in the construction of equipment for the petrochemical, refining, and energy industries, including parts for high-temperature furnaces, heat exchangers, and other critical components in corrosive environments. Its ability to perform under severe conditions makes it suitable for advanced engineering applications where reliability is crucial.

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.