Welcome to our company!

Equivalent grade:

● CuNi90/10

● BFe-10-1-1

● DIN CuNi10Fe1Mn

◉ Available Products

Flange

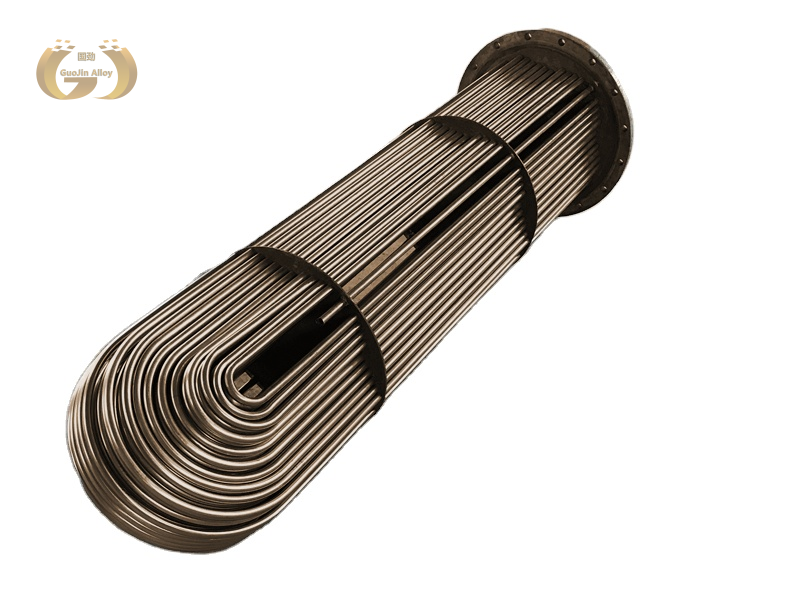

U pipe

Coil tube

Pipe fittings(Tee, Elbow,Reducer...)

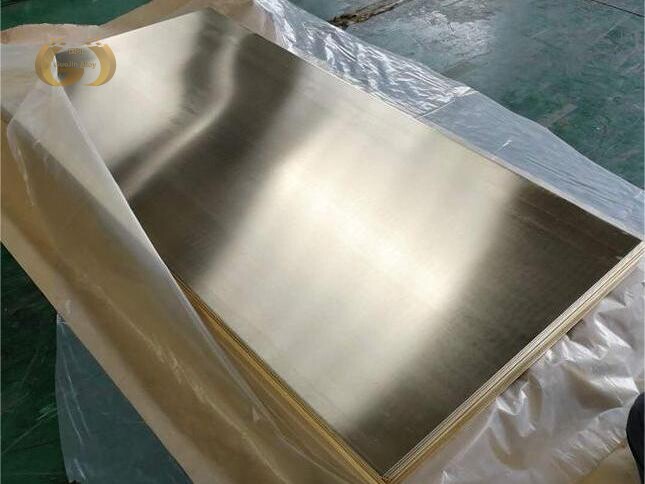

Plate/Sheet

Bar/Rod

Pipe/Tube

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

C70600 Material Properties

BFe10-1-1 (UNSC70600) alloy is a copper alloy with nickel, iron and manganese as the main added elements. It has good corrosion resistance, machinability, ductility, electrical conductivity, thermal conductivity and excellent seawater antifouling performance , widely used in the field of warships, aircraft carriers, nuclear submarines and other weapons and equipment manufacturing, as well as heat exchangers, condenser tubes, seawater desalination devices and other fields.

Advantages

1. Excellent corrosion resistance in seawater

2. High resistance to erosion and biofouling

3. Good mechanical properties

4. Excellent weldability and fabricability

5. Long service life in marine environments

6. Low susceptibility to stress corrosion

7. Cost-effective compared to alternative alloys

8. Resistant to pitting and crevice corrosion

9. Good thermal stability at elevated temperatures

10. Versatile for various marine applications

Application areas of C70600 material

BFe10-1-1 (UNSC70600) nickel cupronickel pure copper plus nickel can significantly improve the strength, corrosion resistance, hardness, resistance and thermoelectricity, and reduce the temperature coefficient of resistivity. Therefore, compared with other copper alloys, cupronickel has exceptionally good mechanical properties and physical properties, good ductility, high hardness, beautiful color, corrosion resistance, and deep drawing properties. It is widely used in ships, petrochemicals, electrical appliances, instruments, medical equipment, Daily necessities, handicrafts and other fields, or resistance and thermocouple alloys.

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.