Welcome to our company!

Equivalent grade:

● DIN W. Nr. 1.4362

● ASTM A182 F68

● EDX 2304

● EN 1.4362

● X2CrNiN23-4

● SAF 2304

● UR 35N

◉ Available Products

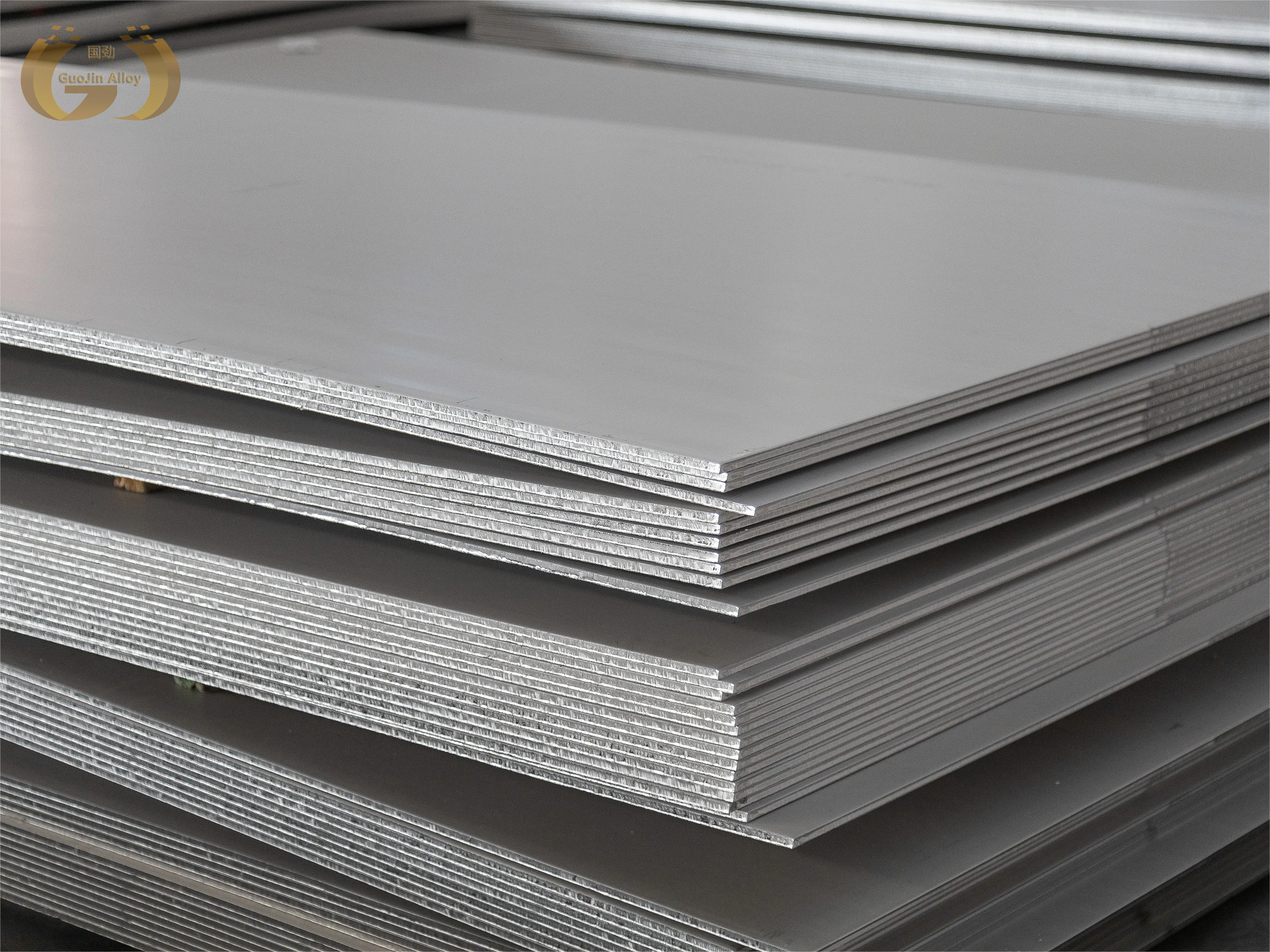

Plate/Sheet

Bar/Rod

Pipe/Tube

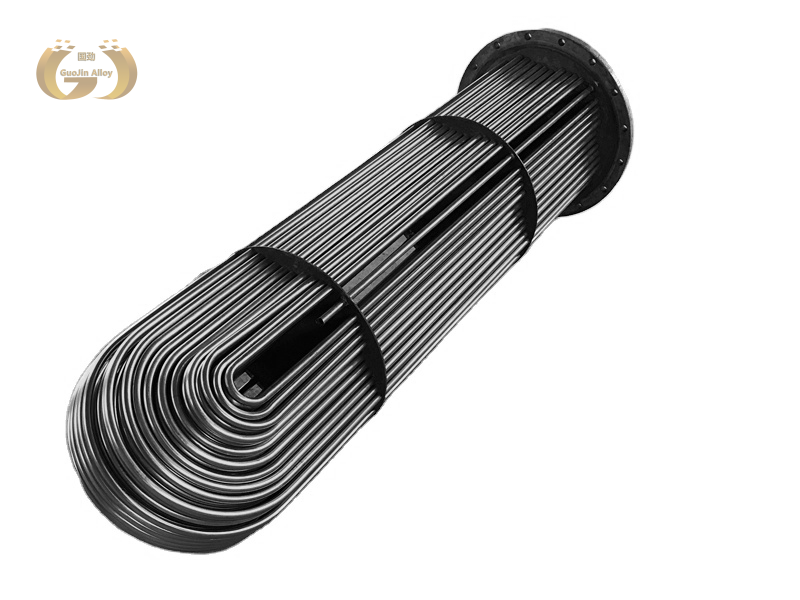

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

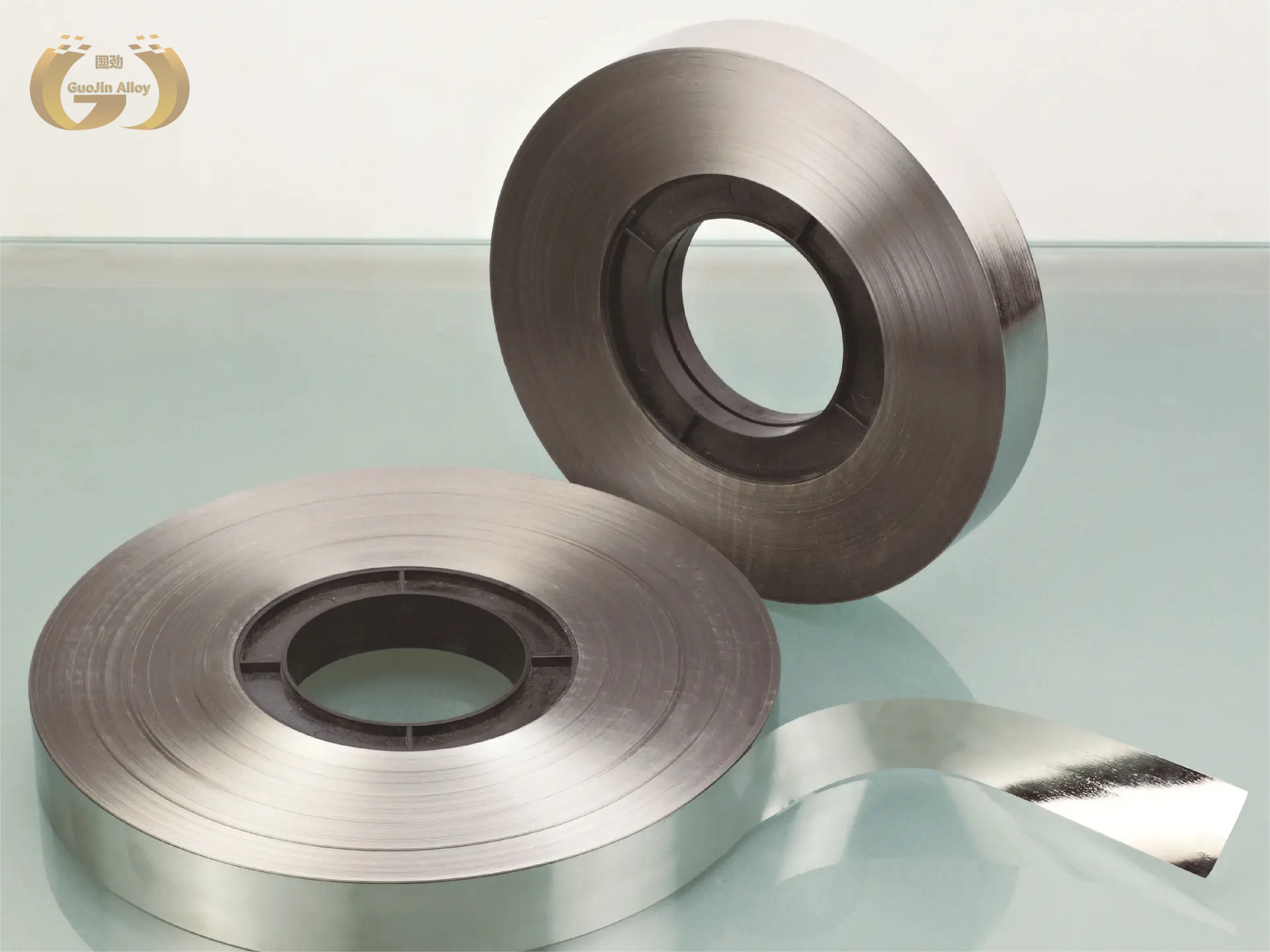

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

S32304 material properties

UNS S32304 belongs to the American standard dual-phase steel, the implementation standard: ASTM A240/A270M-2017

It is a duplex stainless steel consisting of 23% chromium and 4% nickel. The corrosion resistance properties of 2304 alloy are similar to those of 316L. In addition, its mechanical properties, yield strength, are twice that of the 304L/316L austenitic grades. This feature enables designers to reduce the weight of products when designing products, especially pressure vessels.

This alloy is particularly suitable for use in the -50°C /+300°C (-58°F/572°F) temperature range. Lower temperatures can also be used under strictly limited conditions (especially for welded structures). Compared with 304 and 316 austenite, the 2304 alloy has stronger stress corrosion resistance due to its dual-phase microstructure, lower nickel content and higher chromium content.

Advantage

1. High strength and toughness for demanding applications.

2. Excellent resistance to corrosion and pitting in aggressive environments.

3. Good weldability and formability for versatile fabrication options.

4. Enhanced resistance to stress corrosion cracking for prolonged service life.

5. Cost-effective compared to higher alloyed stainless steels.

6. Low thermal expansion for dimensional stability in various conditions.

7. Superior machinability for efficient processing and manufacturing.

8. Suitable for use in chloride-containing environments without compromise.

9. Improved resistance to fatigue and erosion for reliable performance.

10.Versatile for a wide range of industrial and marine applications.

S32304 material application areas

2304 duplex stainless steel has good mechanical and physical properties, resistance to stress corrosion and other corrosion forms and good weldability, making it possible to replace austenitic stainless steel such as 304, 304L, 316, 316L and so on. It can be used in the manufacture of amine recovery equipment, fermentation equipment for hydrocarbons, etc. In addition, it can also be used as heat exchangers in the manufacturing industry, digester preheaters in the pulp and paper industry, and train seat frames in humid heat and offshore areas.

1. Most fields used by 304 and 316

2. Pulp and paper industry (chips, chip storage tanks, black or white liquid tanks, sorters)

3. Caustic solution, organic acid (anti-SCC)

4. Food industry

5. Pressure Vessels (to reduce weight)

6. Mining (abrasive/corrosion)

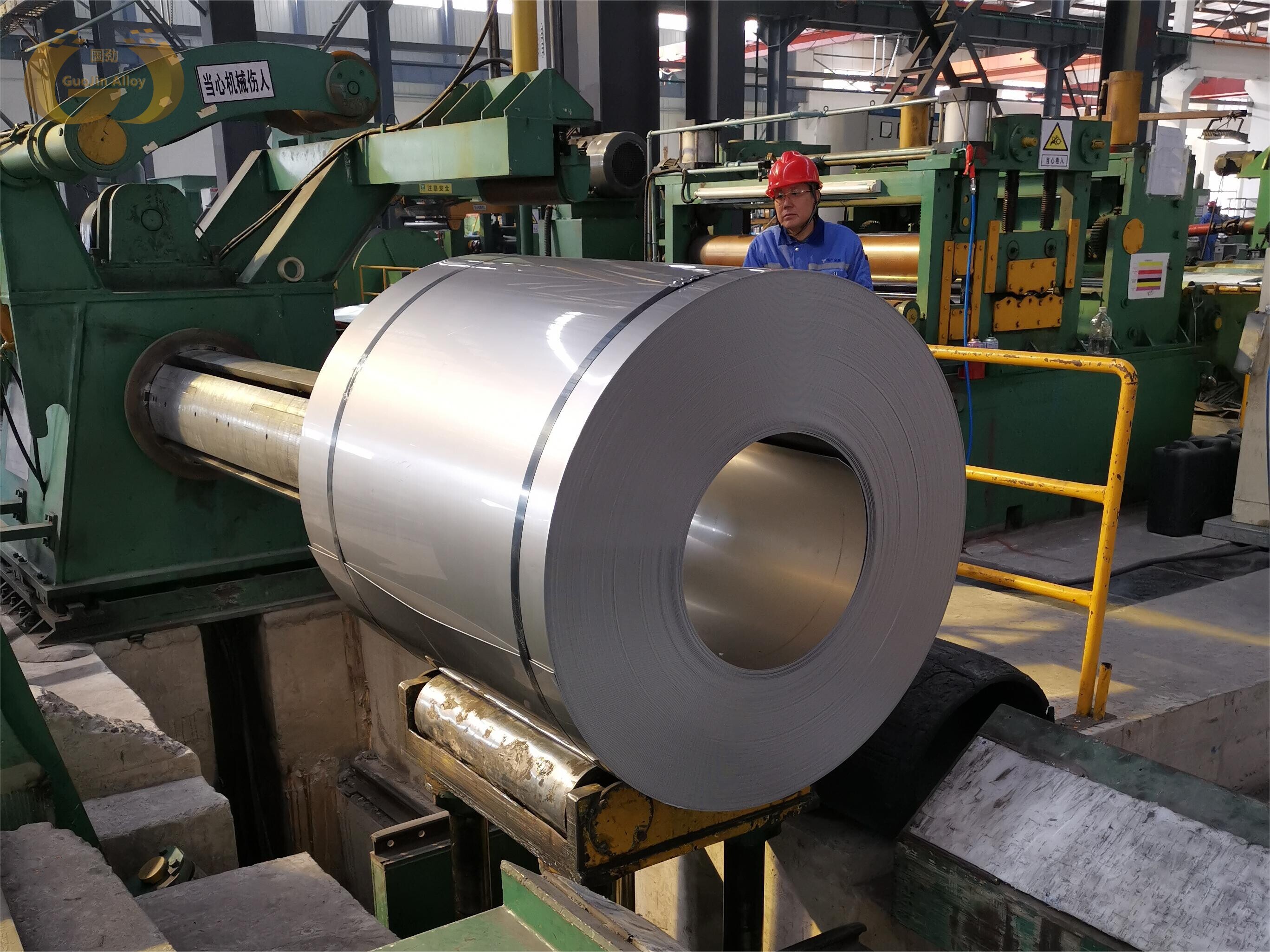

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.