Welcome to our company!

Equivalent grade:

● Alloy 800

● UNS N08800

◉ Available Products

Plate/Sheet

Bar/Rod

Pipe/Tube

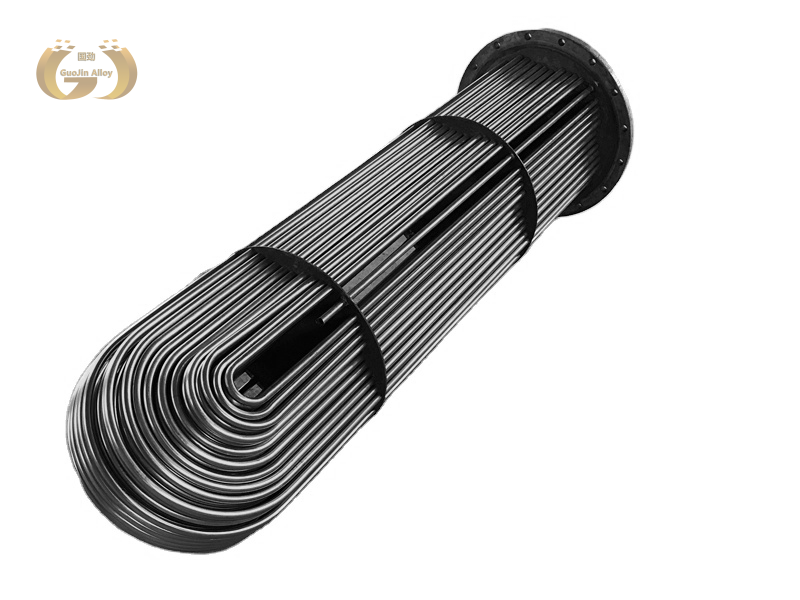

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

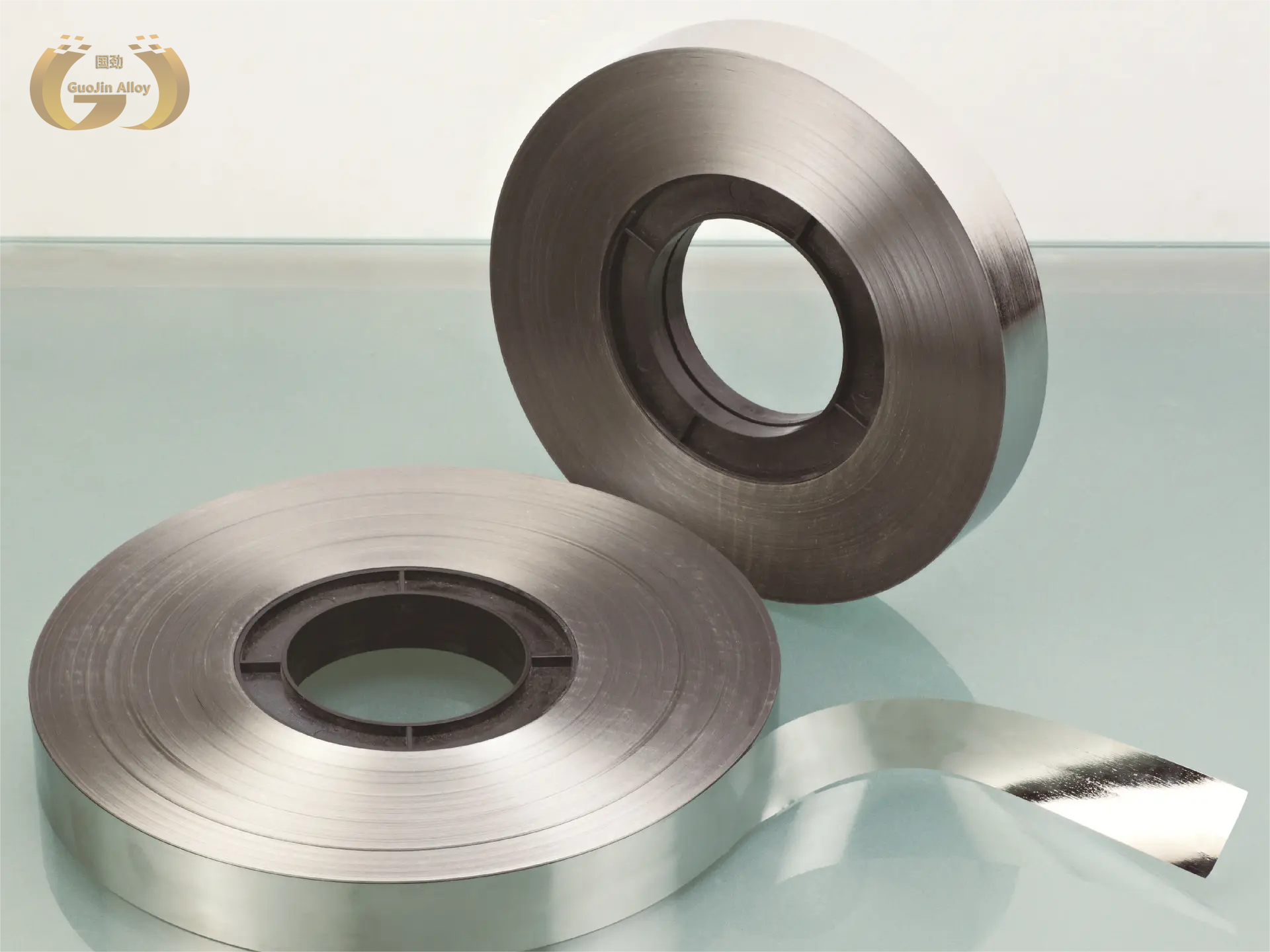

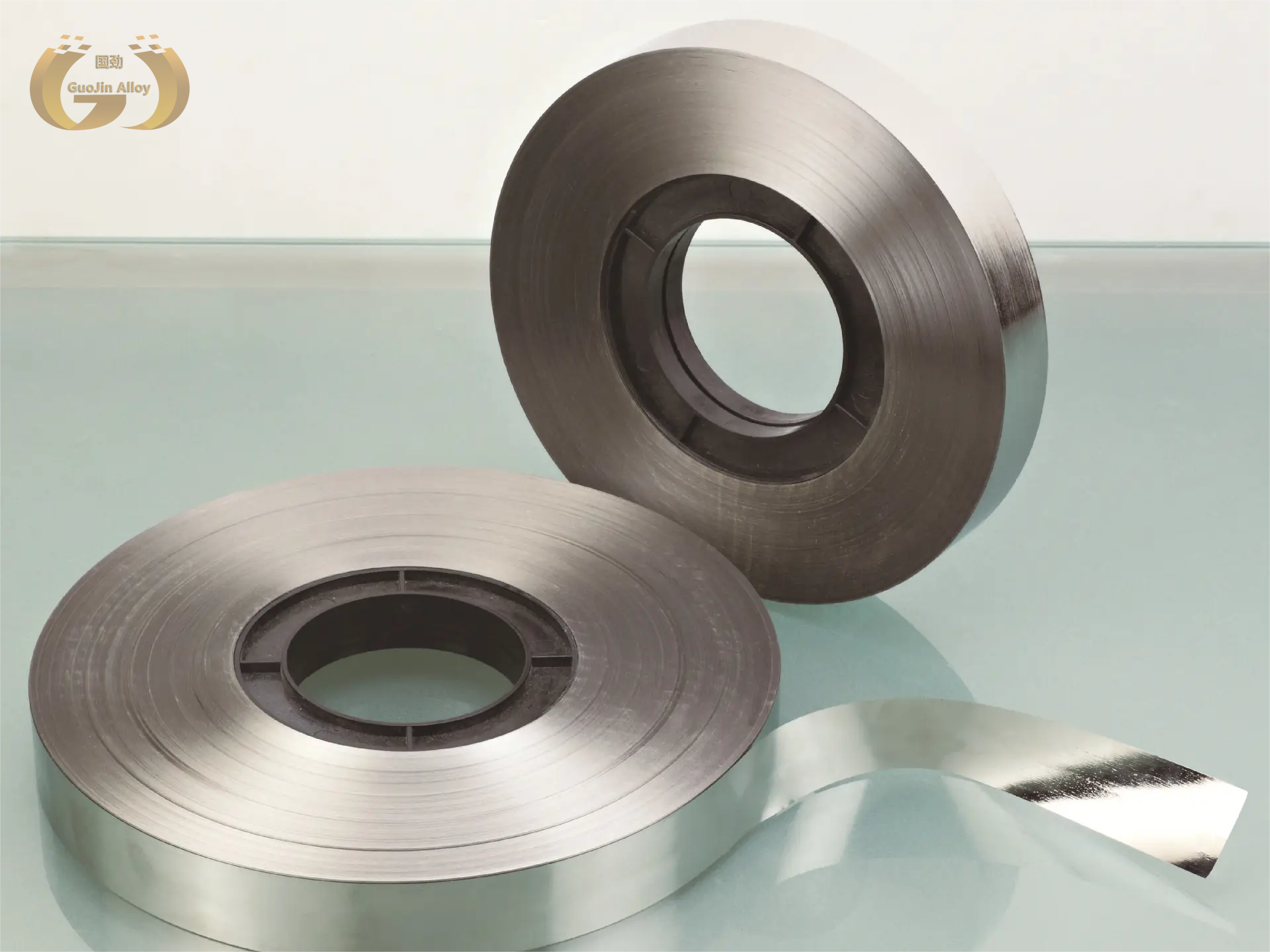

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

Incoloy 800 Features

The Cr content in Incoloy 800 alloy is usually 15-25%, the nickel content is 30-45%, and contains small amounts of aluminum and titanium. Incoloy800 alloy is in the austenite single-item region after rapid cooling from high temperature, so the use state is a single austenite structure. The alloy has high chromium content and sufficient nickel content, so it has high high temperature corrosion resistance and is widely used in industry. In chloride, low concentration NaOH aqueous solution and high temperature and high pressure water, it has excellent resistance to stress corrosion cracking, so it is used to manufacture equipment that is resistant to stress corrosion cracking.It has excellent corrosion resistance, good stress corrosion resistance and good processability in extremely high temperature aqueous media up to 500℃.

Advantage

1. High temperature strength for demanding industrial environments.

2. Excellent corrosion resistance against various acidic and alkaline environments.

3. Good thermal stability ensures reliability in extreme heat conditions.

4. Superior oxidation resistance for prolonged component lifespan.

5. Versatile fabrication options for diverse engineering applications.

6. Outstanding creep and stress rupture properties ensure long-term durability.

7. Low risk of embrittlement, maintaining structural integrity over time.

8. Wide availability and proven track record in critical industries.

Incoloy800 application areas

Nitric acid condenser - corrosion resistant to nitric acid, steam heating tube - good mechanical properties, heating element tube - good mechanical properties, for applications up to 500°C, the alloy is supplied in the annealed condition.

1.Chemical industry

2.Nuclear generator

3.Nitric acid cooler, acetic anhydride cracking tube

4.Heat exchange equipment, heat exchange tubes

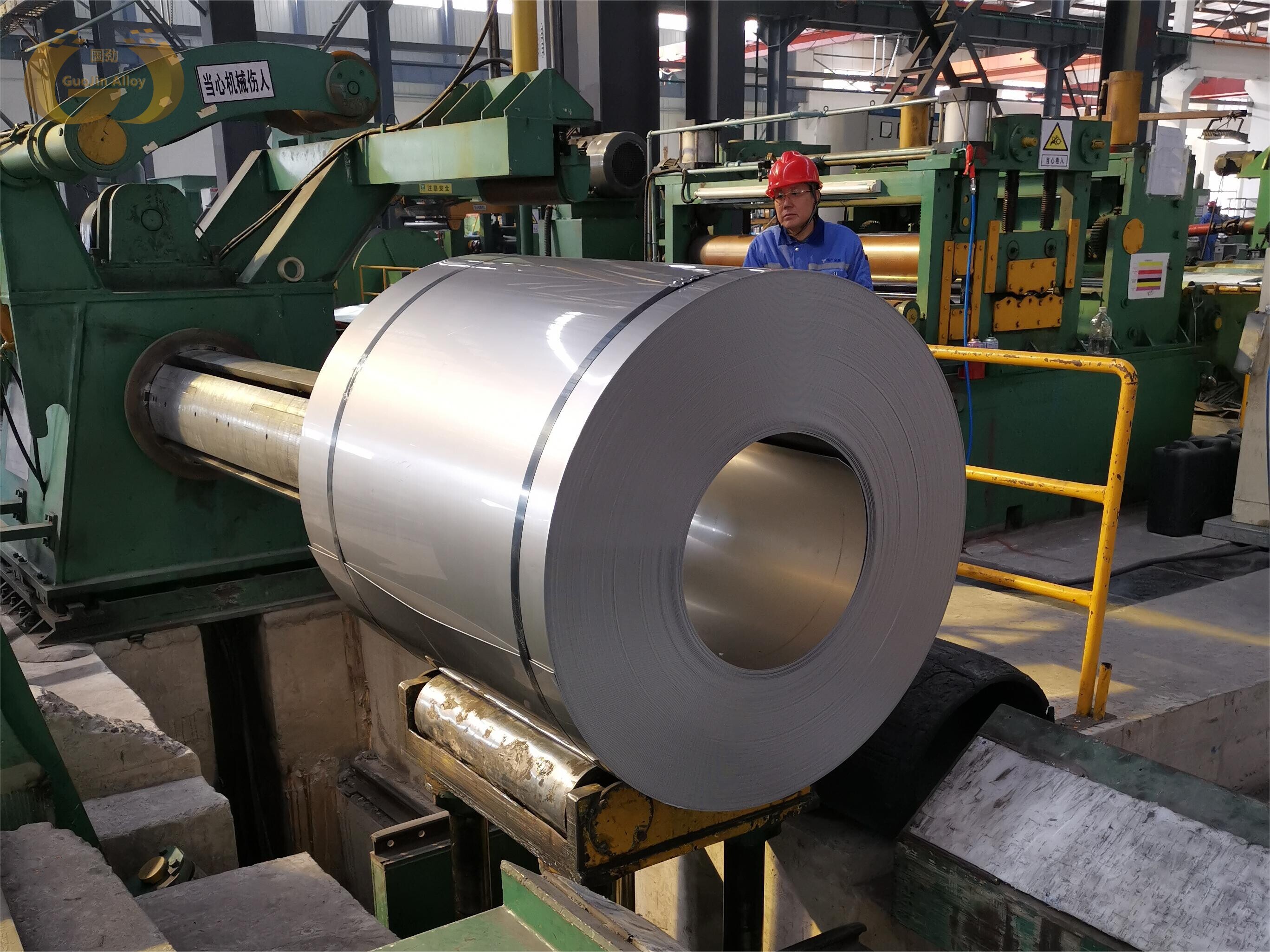

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.