Welcome to our company!

Equivalent grade:

● ASTM A182 F60

● DIN W. Nr. 1.4462

● EN 1.4462

● X2CrNiMoN22-5-3

● SAF 2205

● UR 45N

● Z3 CN 22-05 AZ:

◉ Available Products

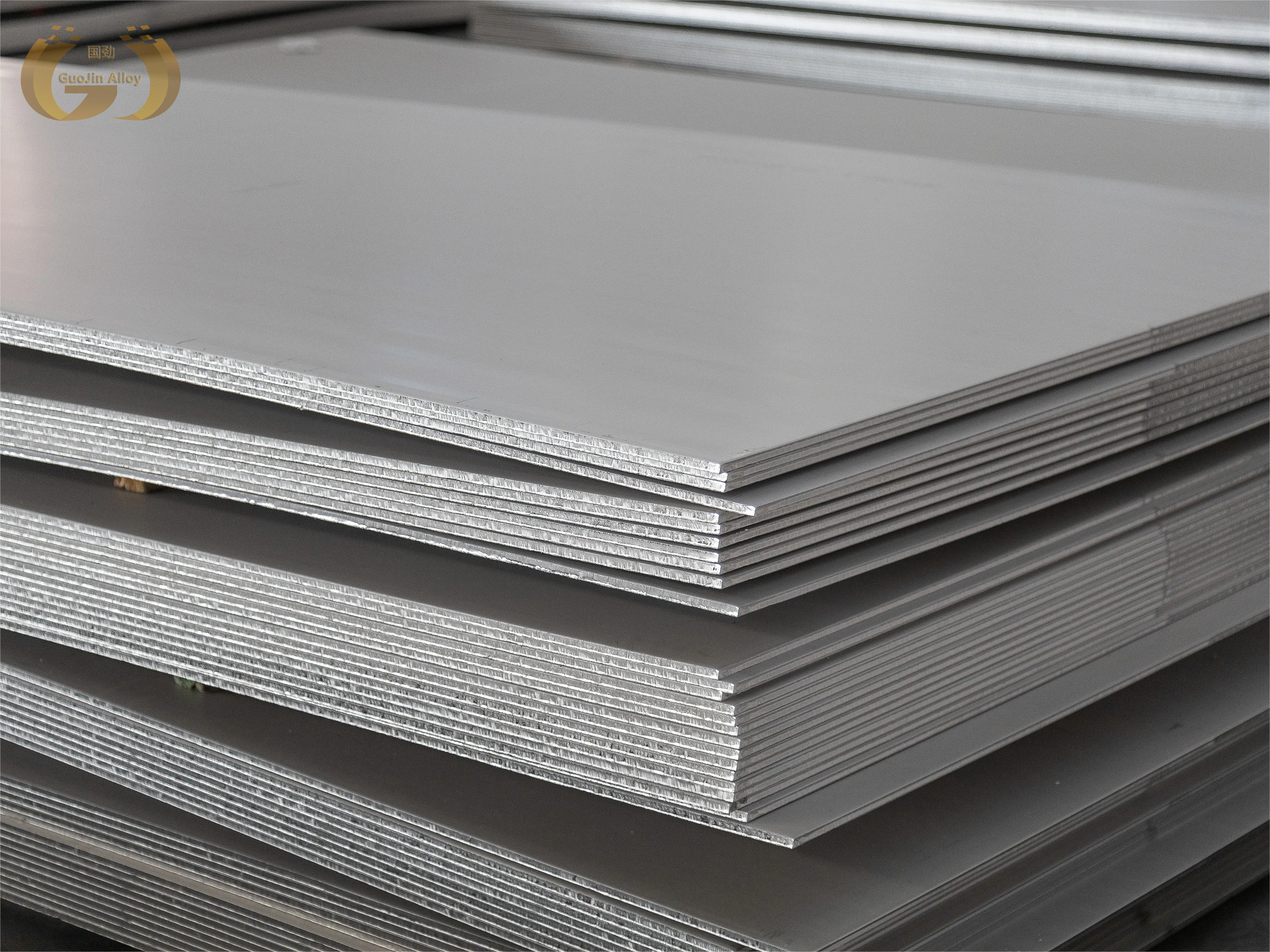

Plate/Sheet

Bar/Rod

Pipe/Tube

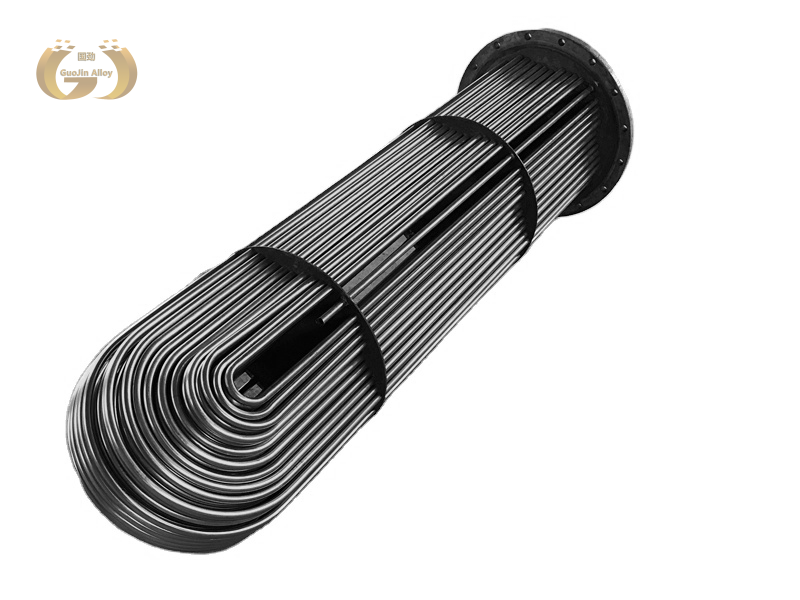

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

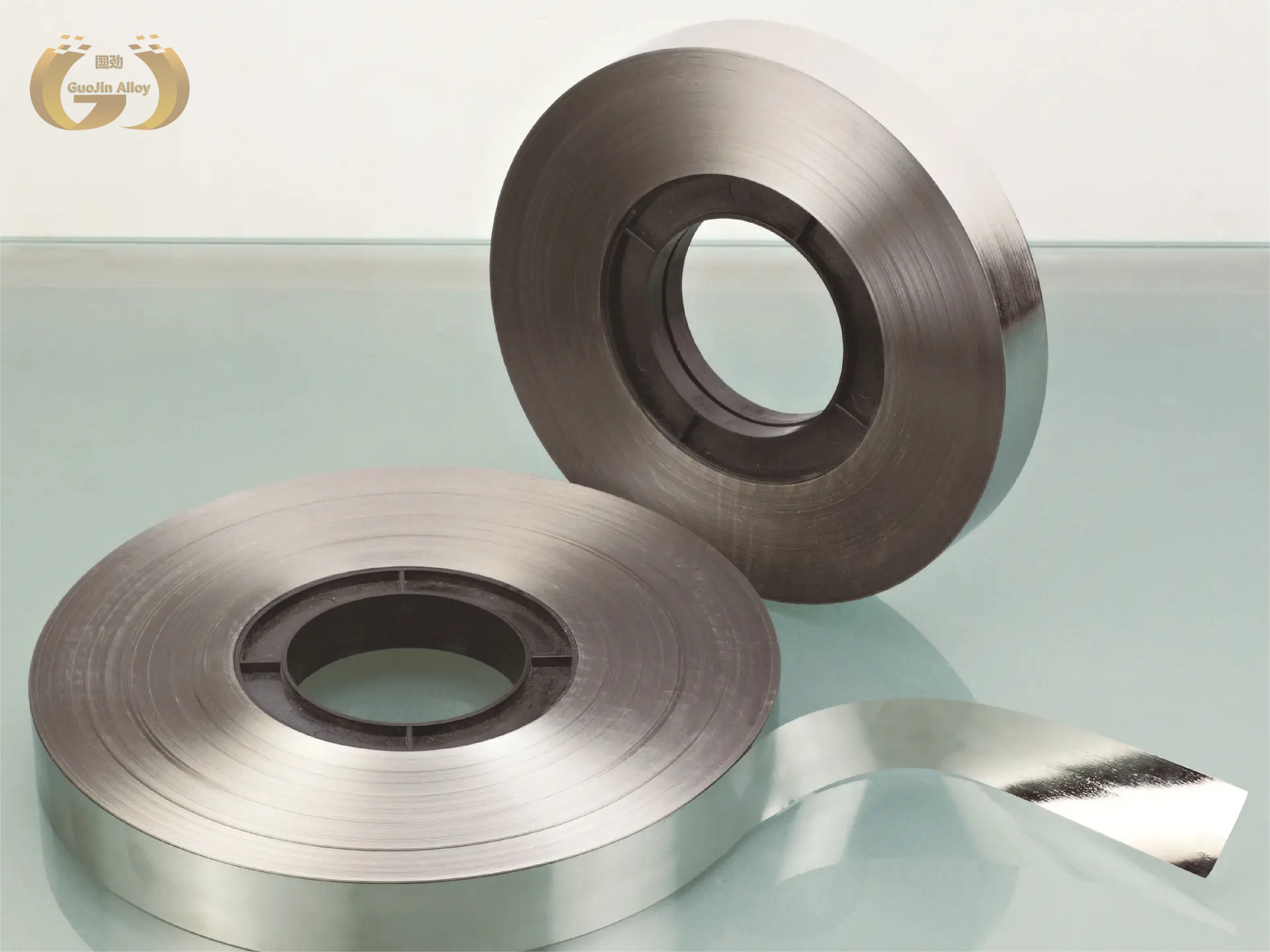

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

S32205 material properties

ASTM A240/A240M--01 Duplex stainless steel 2205 alloy is a duplex stainless steel composed of 22% chromium, 2.5% molybdenum and 4.5% nickel-nitrogen alloy. It has high strength, good impact toughness and good overall and local stress corrosion resistance. The yield strength of 2205 duplex stainless steel is more than double that of ordinary austenitic stainless steel. This feature allows designers to reduce weight when designing products, making this alloy more affordable than 316 and 317L. This alloy is particularly suitable for use in the -50°F/+600°F temperature range. For applications outside this temperature range, this alloy can also be considered, but there are some limitations, especially when applied to welded structures.

Advantages of S32205 Duplex Steel

1. Stronger than standard stainless steel.

2. Excellent stress corrosion resistance.

3. Better overall corrosion resistance.

4. Improved wear and fatigue resistance.

5. Compatible with carbon steel.

6. Higher energy absorption capacity.

S32205 material application areas

Pressure vessels, high-pressure storage tanks, high-pressure pipes, heat exchangers (chemical processing industry).

1. Oil and gas pipelines, heat exchanger fittings.

2. Sewage treatment system.

3. Pulp and paper industry classifiers, bleaching plants, storage and treatment systems.

4. Rotary shafts, press rolls, blades, impellers, etc. in high-strength and corrosion-resistant environments.

5. Cargo boxes for ships or trucks

6. Food processing equipment

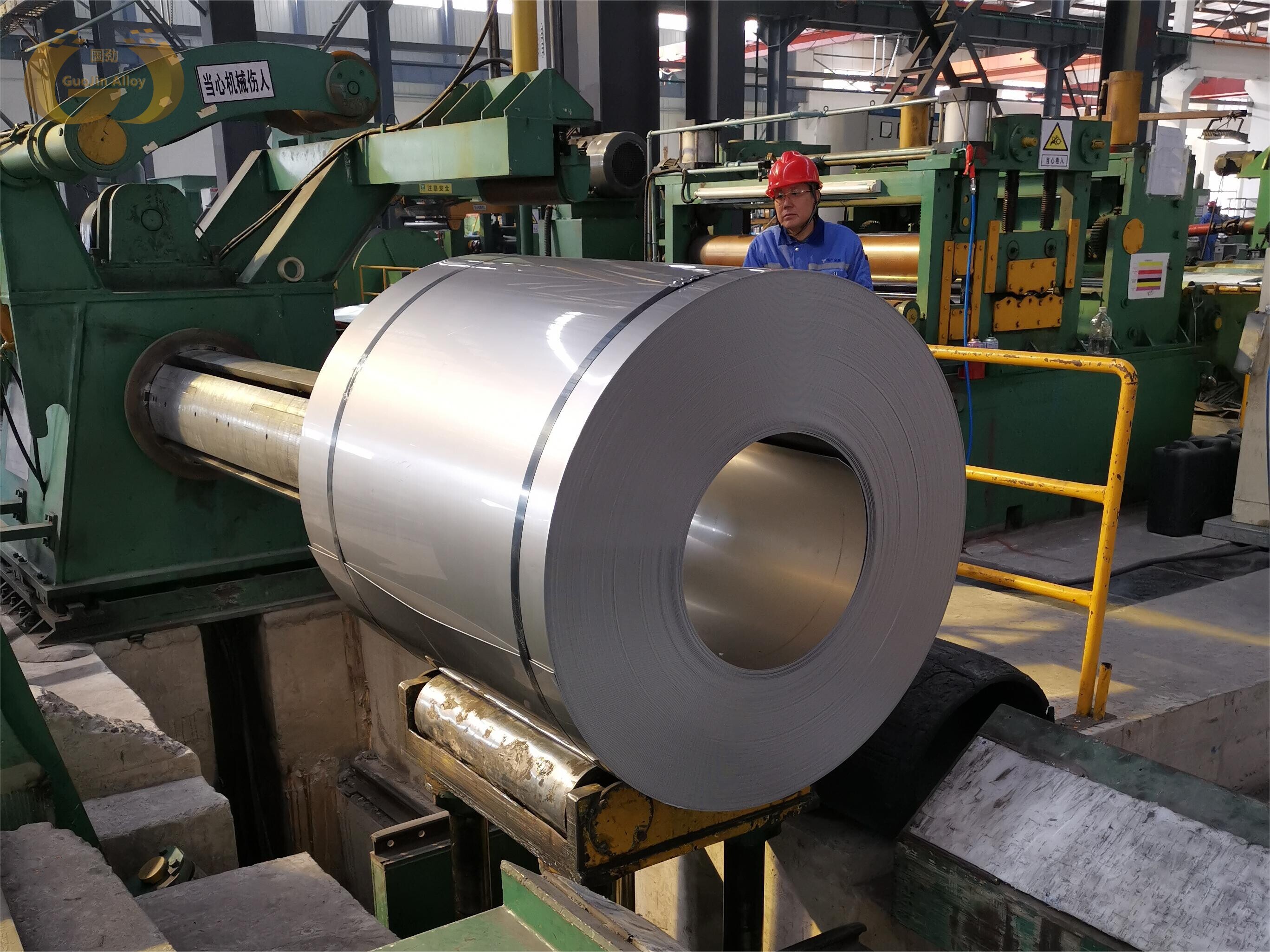

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.