Welcome to our company!

Equivalent grade:

● DIN W. Nr. 1.4462

● EN 1.4462

● X2CrNiMoN22-5-3

● SAF 2205

● Z3 CN 22-05 AZ

● ASTM A182 F51

◉ Available Products

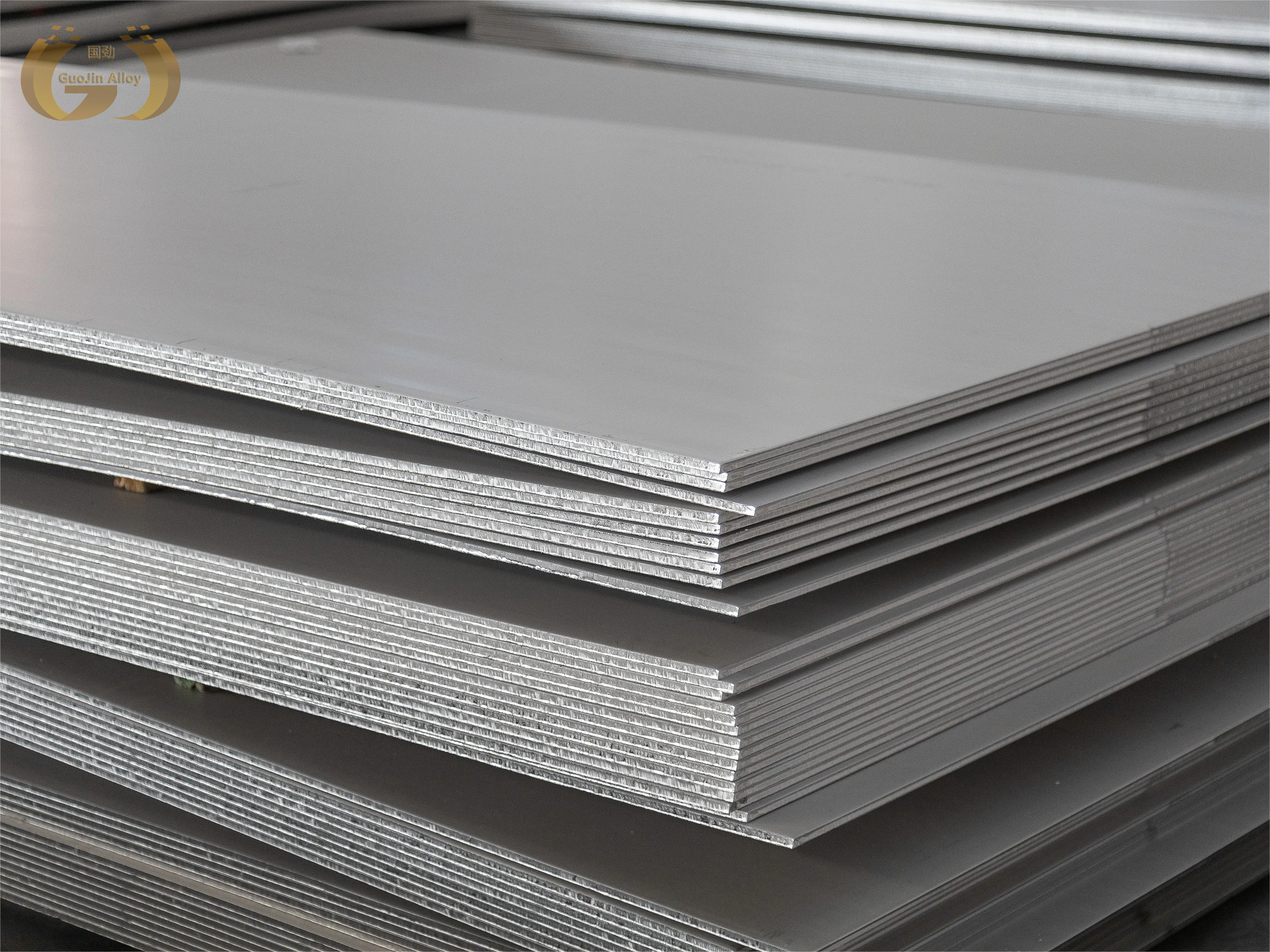

Plate/Sheet

Bar/Rod

Pipe/Tube

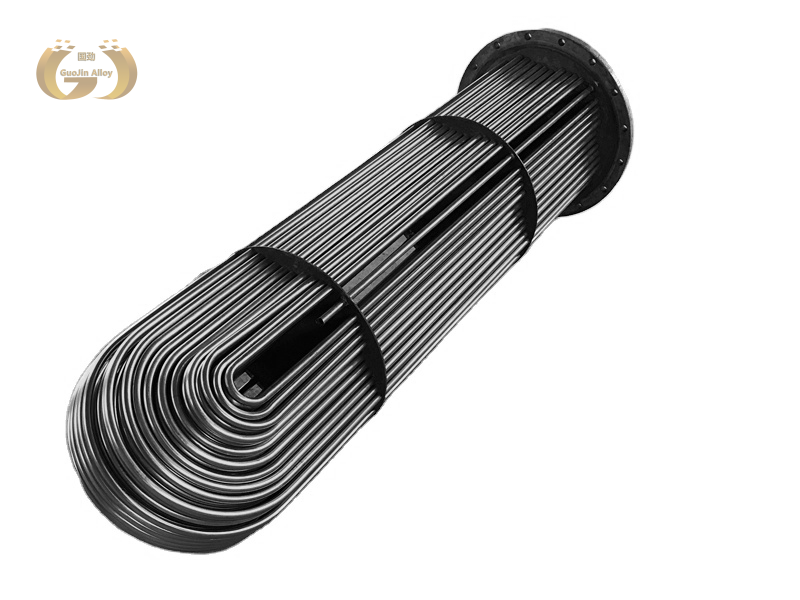

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

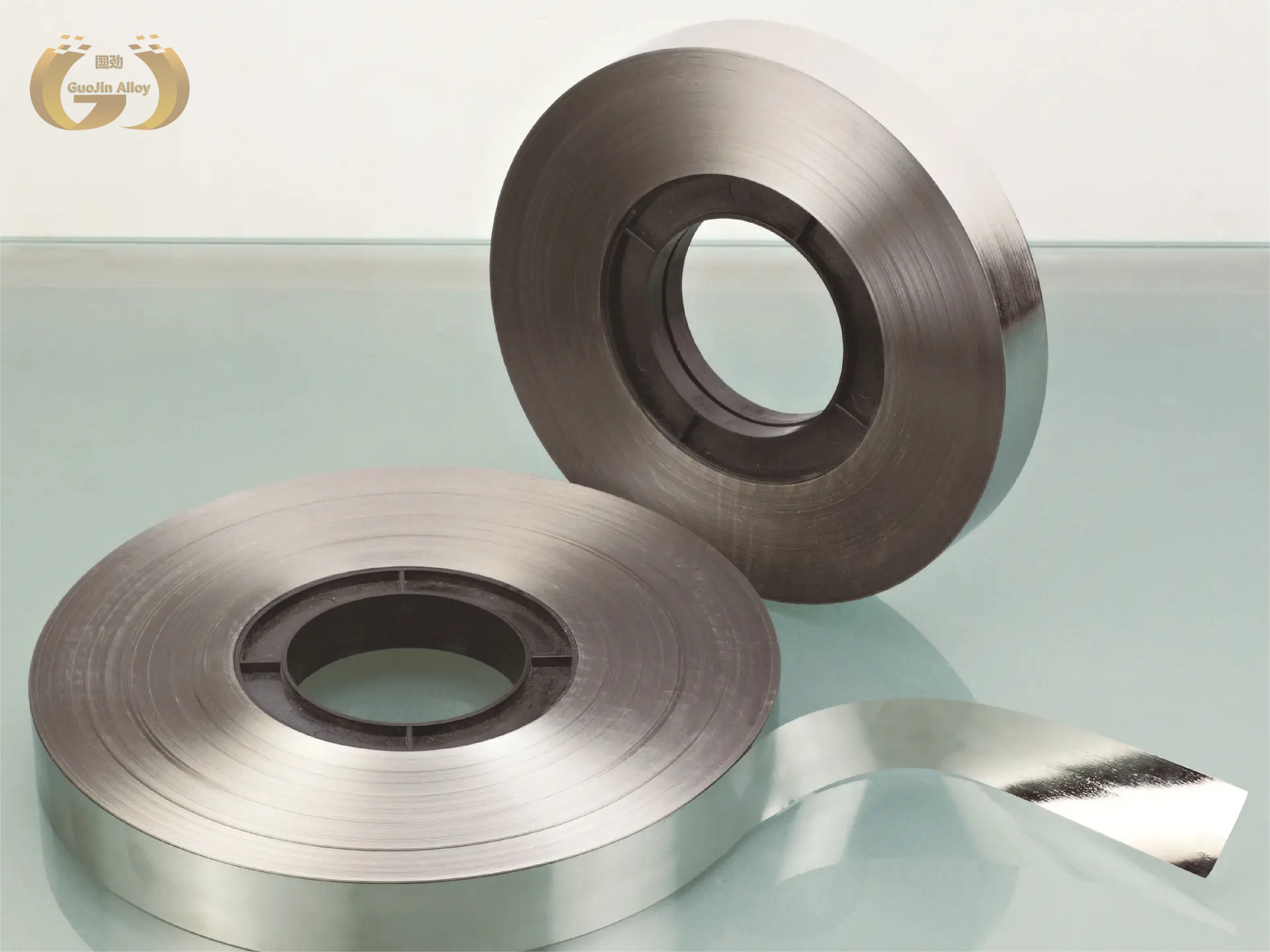

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

S31803 material properties

S31803 is a duplex stainless steel alloy characterized by a mixed microstructure of austenite and ferrite phases. It offers high strength, excellent corrosion resistance, and good weldability, making it suitable for various demanding applications. With its superior mechanical properties and resistance to corrosion, S31803 is widely utilized in industries requiring reliable performance in aggressive environments.

Advantage

1. High strength and toughness

2. Superior corrosion resistance

3. Good weldability and formability

4. Resistant to stress corrosion cracking

5. Cost-effective compared to high-alloy steels

6. Suitable for aggressive environments

7. Versatile for a wide range of applications

8. Long service life in challenging conditions

9. Resistance to chloride-induced pitting corrosion

10. Enhanced durability in harsh environments

S31803 material application areas

S31803 finds extensive use in industries such as chemical processing, oil and gas, marine, and desalination. It is employed in pipelines, heat exchangers, pressure vessels, and structural components requiring high strength and corrosion resistance. The alloy's versatility and durability make it ideal for applications where performance and reliability are paramount, even in challenging conditions such as corrosive and high-pressure environments.

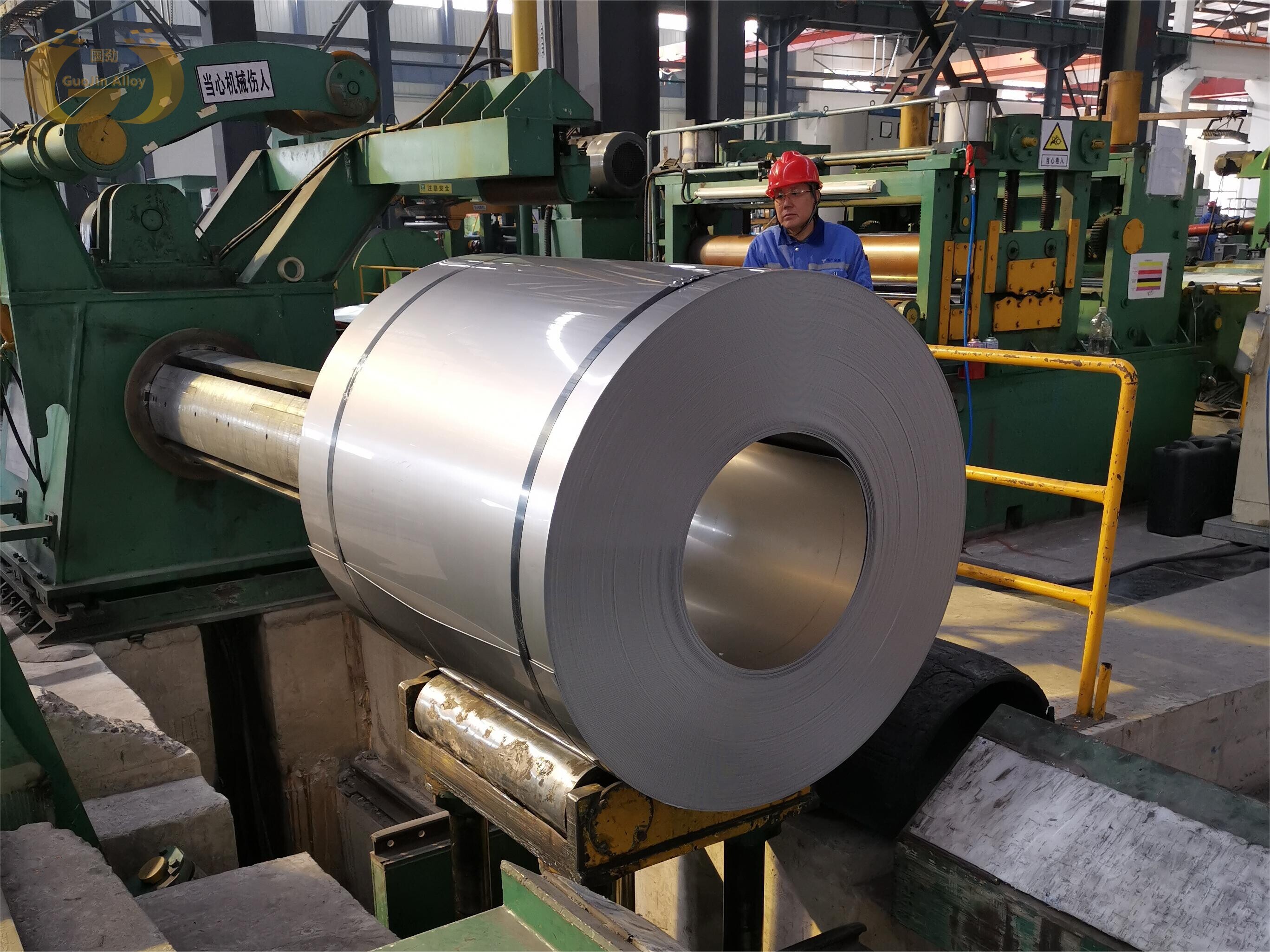

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.