Welcome to our company!

Equivalent grade:

● Alloy C-276

● DIN W. Nr. 2.4819

◉ Available Products

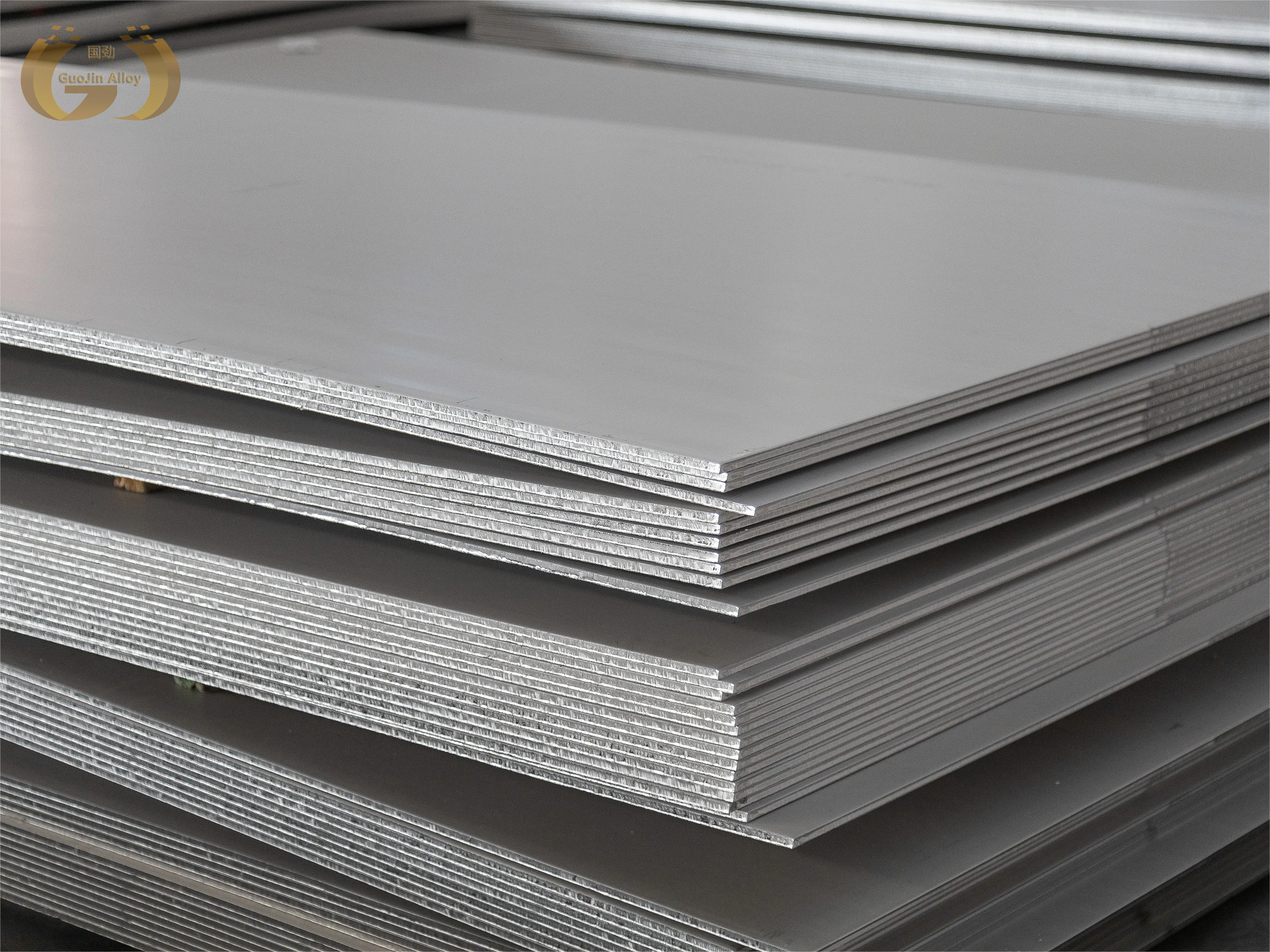

Plate/Sheet

Bar/Rod

Pipe/Tube

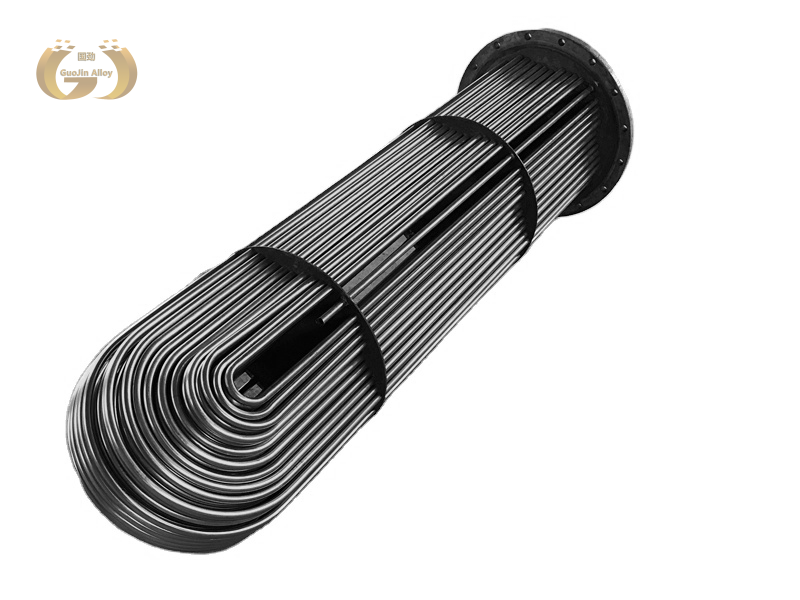

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

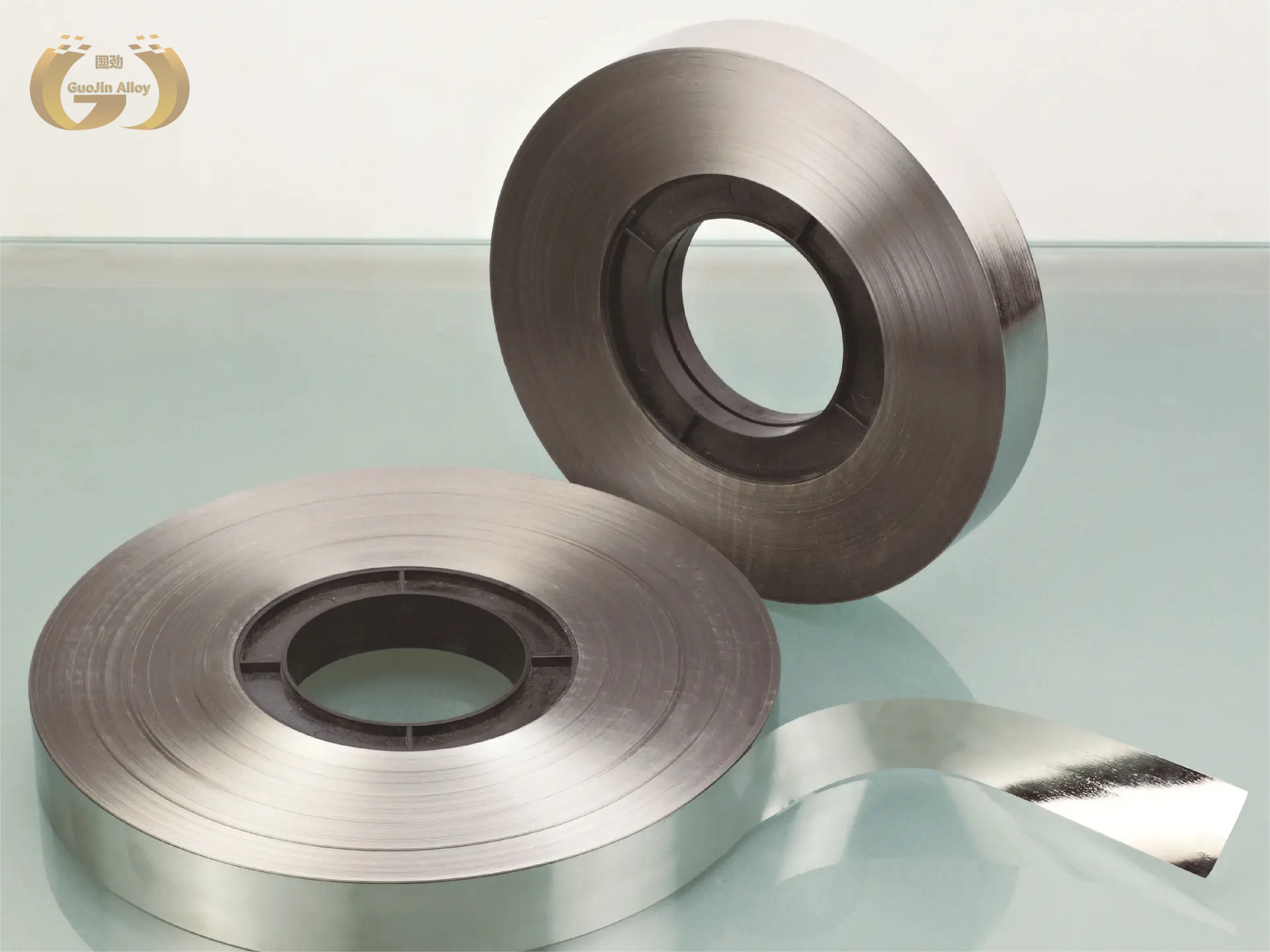

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

Introduction

Hastelloy C276, a highly versatile nickel-molybdenum-chromium-tungsten alloy, boasts exceptional corrosion resistance across a broad spectrum of aggressive media, both in oxidized and reduced states. Its formidable defense against pitting, crevice corrosion, and stress corrosion cracking, coupled with good machinability, sets it apart. Despite demonstrating good oxidation resistance up to 1800°F, it's typically not suited for extreme high-temperature applications. The alloy's robust composition, enriched with molybdenum and chromium, imparts remarkable resilience against chloride ion corrosion, while tungsten enhances this protection further. Notably, Hastelloy C-276 stands as one of the select few materials capable of withstanding the corrosive effects of moist chlorine, hypochlorite, and chlorine dioxide solutions, even iron and copper chloride. Its ability to resist grain boundary precipitate formation in welded heat-affected zones makes it a prime choice for chemical and petrochemical processing under welding conditions. Moreover, its low carbon content minimizes carbide precipitation during welding, preserving its exceptional corrosion resistance, allowing for seamless fabrication via welding techniques akin to those used for nickel-based alloys.

Advantages of Hastelloy C-276

1. Exceptional corrosion resistance in a wide range of aggressive environments, including oxidizing and reducing conditions.

2. Superior resistance to pitting, crevice corrosion, and stress corrosion cracking.

3. High resistance to chloride-induced corrosion and sulfuric acid.

4. Excellent weldability and fabrication characteristics for ease of manufacturing.

5. Versatile material suitable for various chemical processing applications.

6. High temperature stability, maintaining integrity at elevated temperatures.

7. Low risk of sensitization, ensuring long-term reliability in corrosive environments.

8. Widely available and proven track record in critical industries.

Hastelloy C-276 application areas

C276 alloy has been widely used in chemical and petrochemical fields, such as components and catalytic systems in contact with chlorine-containing organic substances. The material is especially suitable for high temperature, inorganic acid and organic acid mixed with impurities (such as formic acid, acetic acid), seawater corrosion environment.

HASTELLOY C-276 has excellent resistance to a variety of chemical process environments, including thermally polluted inorganic acids, ferric and copper chlorides, solvents, chlorine and chlorine polluted organic and inorganic pollutants, dry chlorine, acetic anhydride, Formic and acetic acids, seawater and brine solutions, chlorine dioxide solutions and hypochlorite.

Other fields of application:

1. Digesters and bleaching agents used in the pulp and paper industry.

2. Absorption tower, reheater and fan in FGD system.

3. Equipment and components used in sour gas environment.

4. Acetic acid and anhydride reaction generator

5. Sulfuric acid cooling

6. MDI

7. Manufacture and processing of impure phosphoric acid.

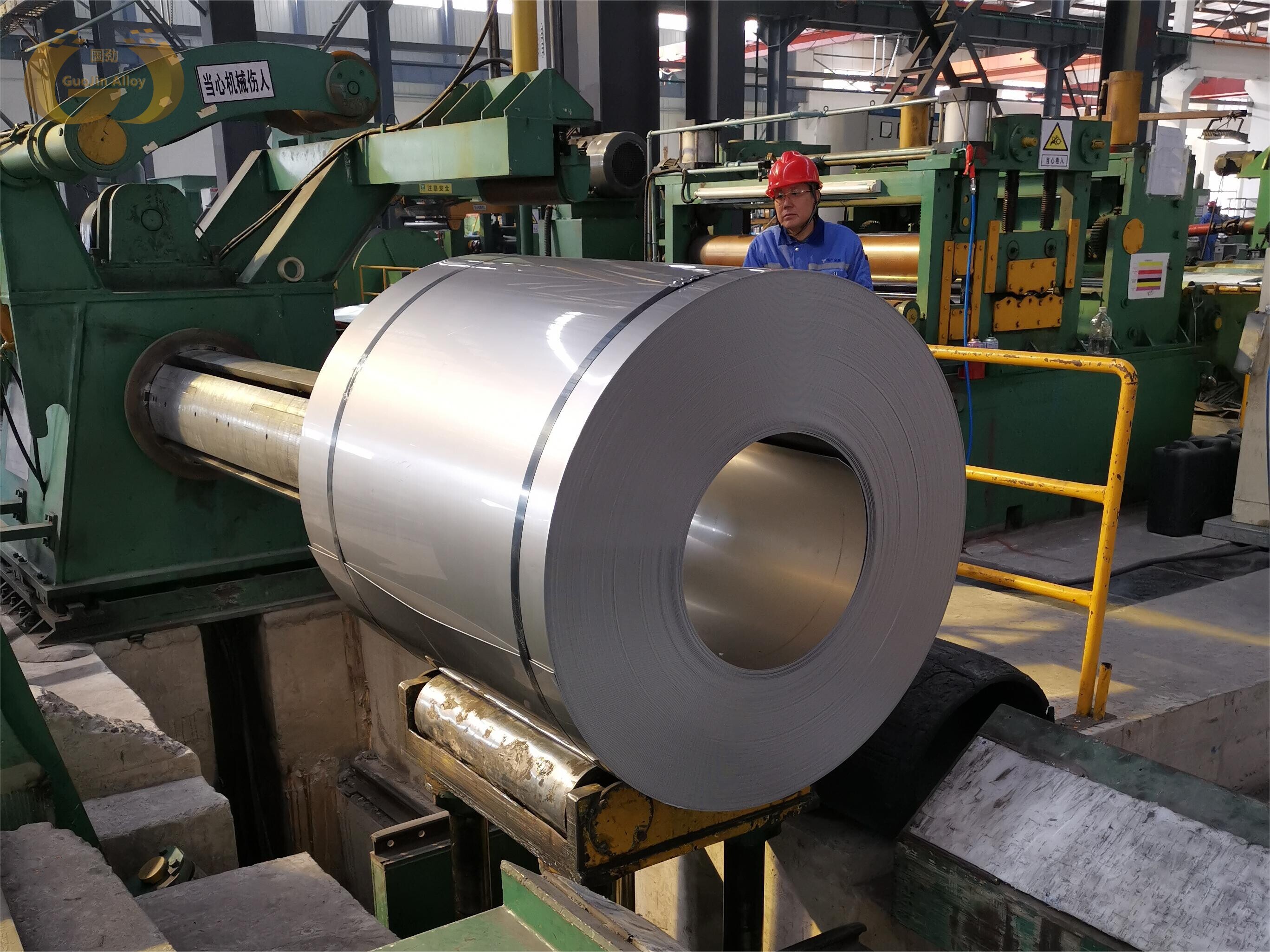

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.