Welcome to our company!

Equivalent grade:

● ASTM A182 F44

● DIN W. Nr. 1.4547

◉ Available Products

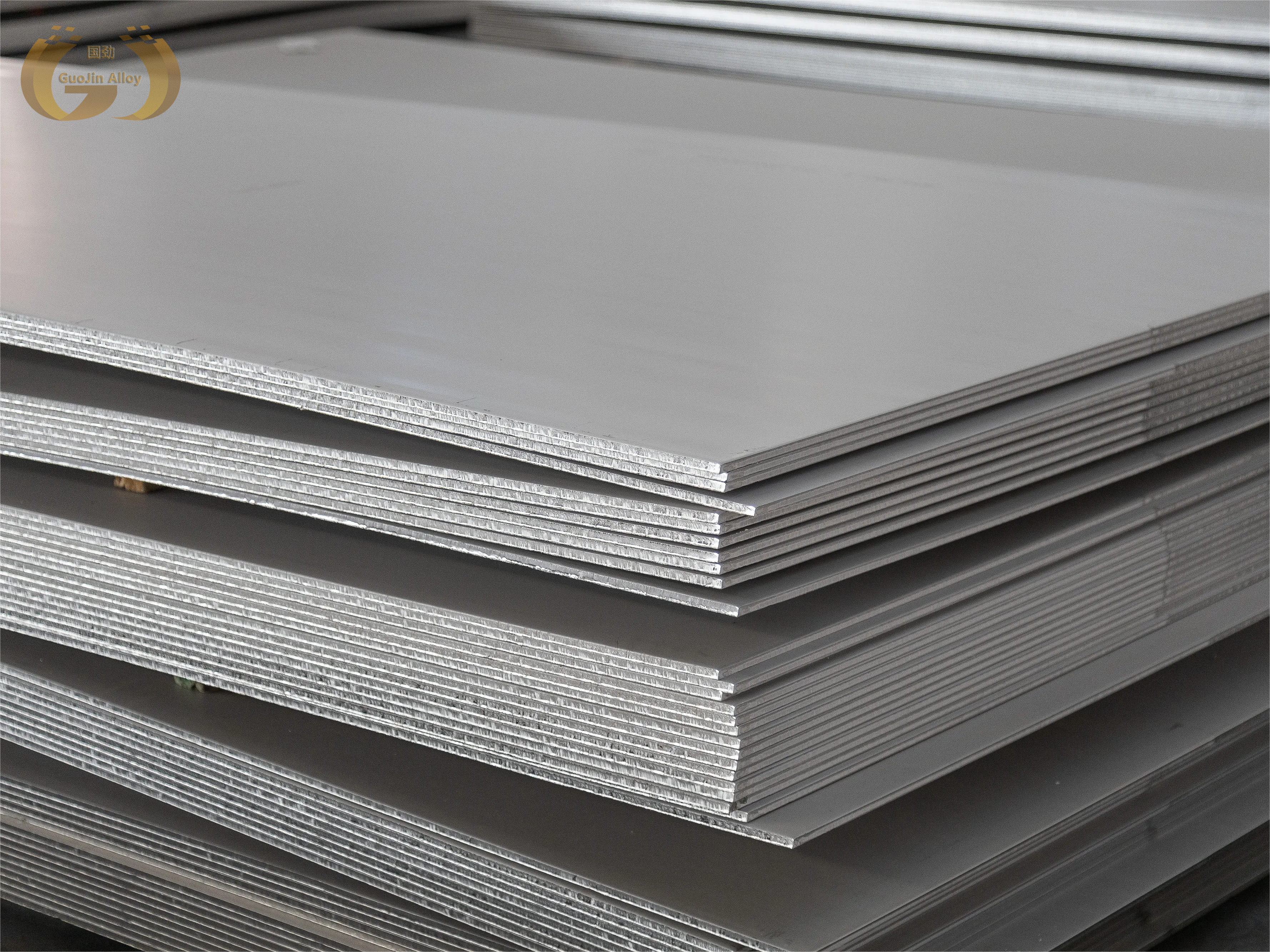

Plate/Sheet

Bar/Rod

Pipe/Tube

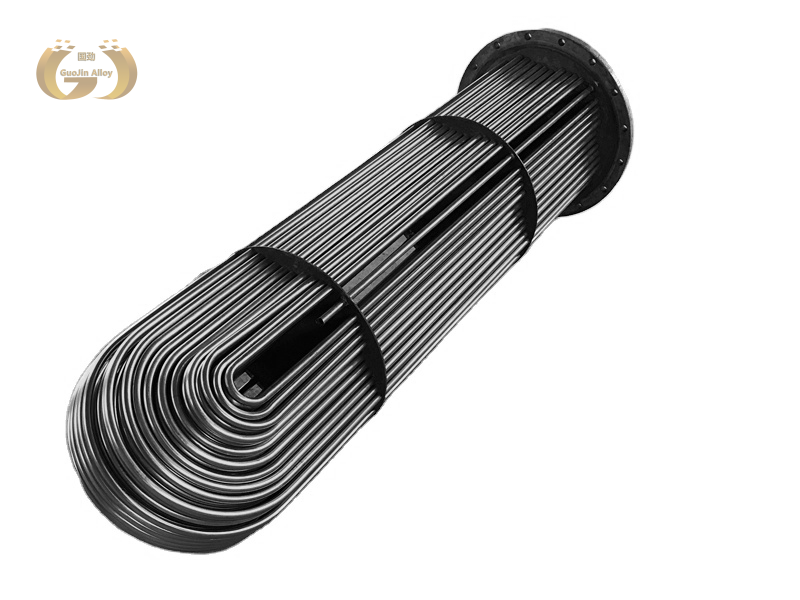

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

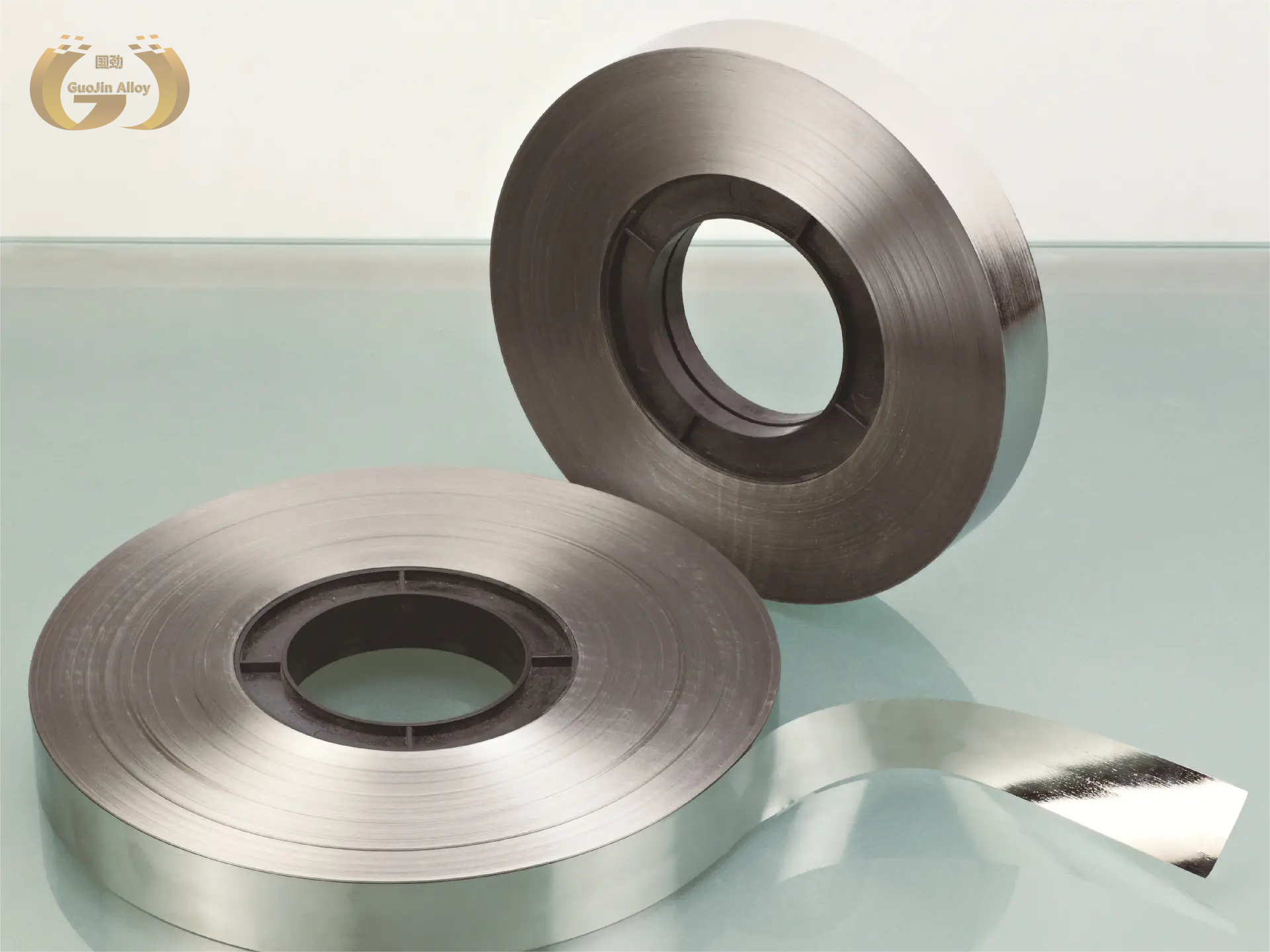

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

254SMo material properties

254SMO is an austenitic stainless steel. Due to its high molybdenum content, it has extremely high resistance to pitting and crevice corrosion. This grade of stainless steel was developed and developed for use in halide-containing environments such as seawater. 254SMO also has good resistance to uniform corrosion. Especially in halide-containing acids, the steel is superior to ordinary stainless steel. Its C contains <0.03%, so it is called pure austenitic stainless steel (<0.01% is also called super austenitic stainless steel). Super stainless steel is a kind of special stainless steel. First of all, it is different from ordinary stainless steel in chemical composition. It refers to a high alloy stainless steel containing high nickel, high chromium and high molybdenum. Among them, the most famous one is 254SMo containing 6% Mo. This kind of steel has very good local corrosion resistance, and has good pitting corrosion resistance (PI≥40) and It has better stress corrosion resistance and is a substitute for Ni-based alloys and titanium alloys. Secondly, in terms of high temperature resistance or corrosion resistance, it has better high temperature resistance or corrosion resistance, which is irreplaceable for 304 stainless steel. In addition, from the classification of stainless steel, the metallographic structure of special stainless steel is a stable austenite metallographic structure.

Since this special stainless steel is a high-alloy material, the manufacturing process is quite complicated. Generally, people can only rely on traditional processes to manufacture this special stainless steel, such as infusion, forging, rolling and so on.

Advantages

1. Superior corrosion resistance in aggressive environments.

2. High resistance to pitting and crevice corrosion.

3. Excellent mechanical properties at elevated temperatures.

4. Good weldability and formability for ease of fabrication.

5. Versatile applicability across industries like chemical processing and oil and gas.

6. Resistance to chloride-induced stress corrosion cracking.

7. Long-term reliability and durability in harsh conditions.

8. Cost-effective solution due to its extended service life and low maintenance requirements.

254SMo material application areas

1. Ocean: marine structures in the marine environment, seawater desalination, seawater aquaculture, seawater heat exchange, etc.

2. Environmental protection field: flue gas desulfurization device for thermal power generation, wastewater treatment, etc.

3. Energy field: nuclear power generation, comprehensive utilization of coal, ocean tide power generation, etc.

4. Petrochemical field: oil refining, chemical and chemical equipment, etc.

5. Food field: salt making, soy sauce brewing, etc.

6. High-concentration chloride ion environment: paper industry, various bleaching devices

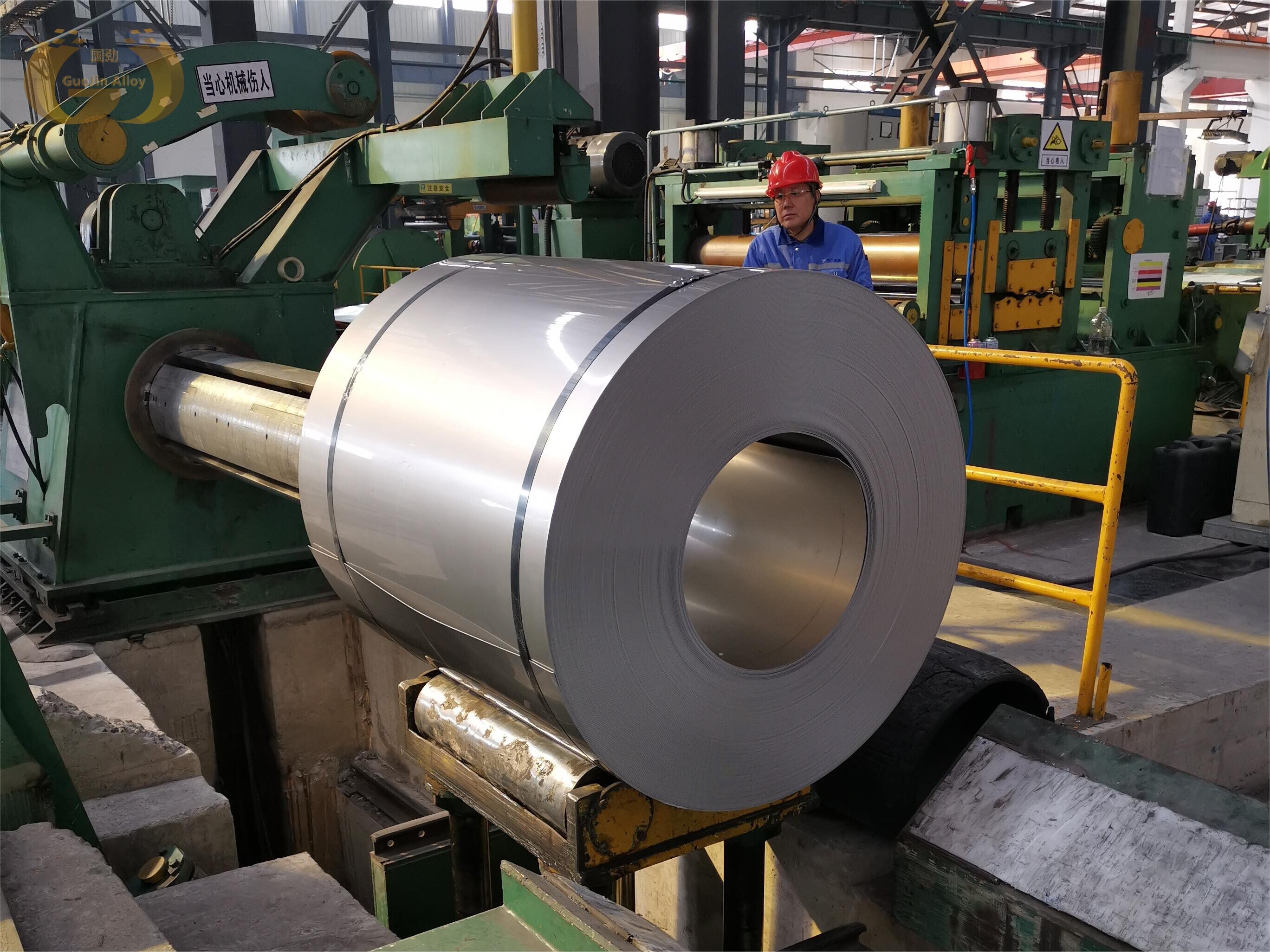

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.