Welcome to our company!

Equivalent grade:

● DIN W. Nr.2.4665

◉ Available Products

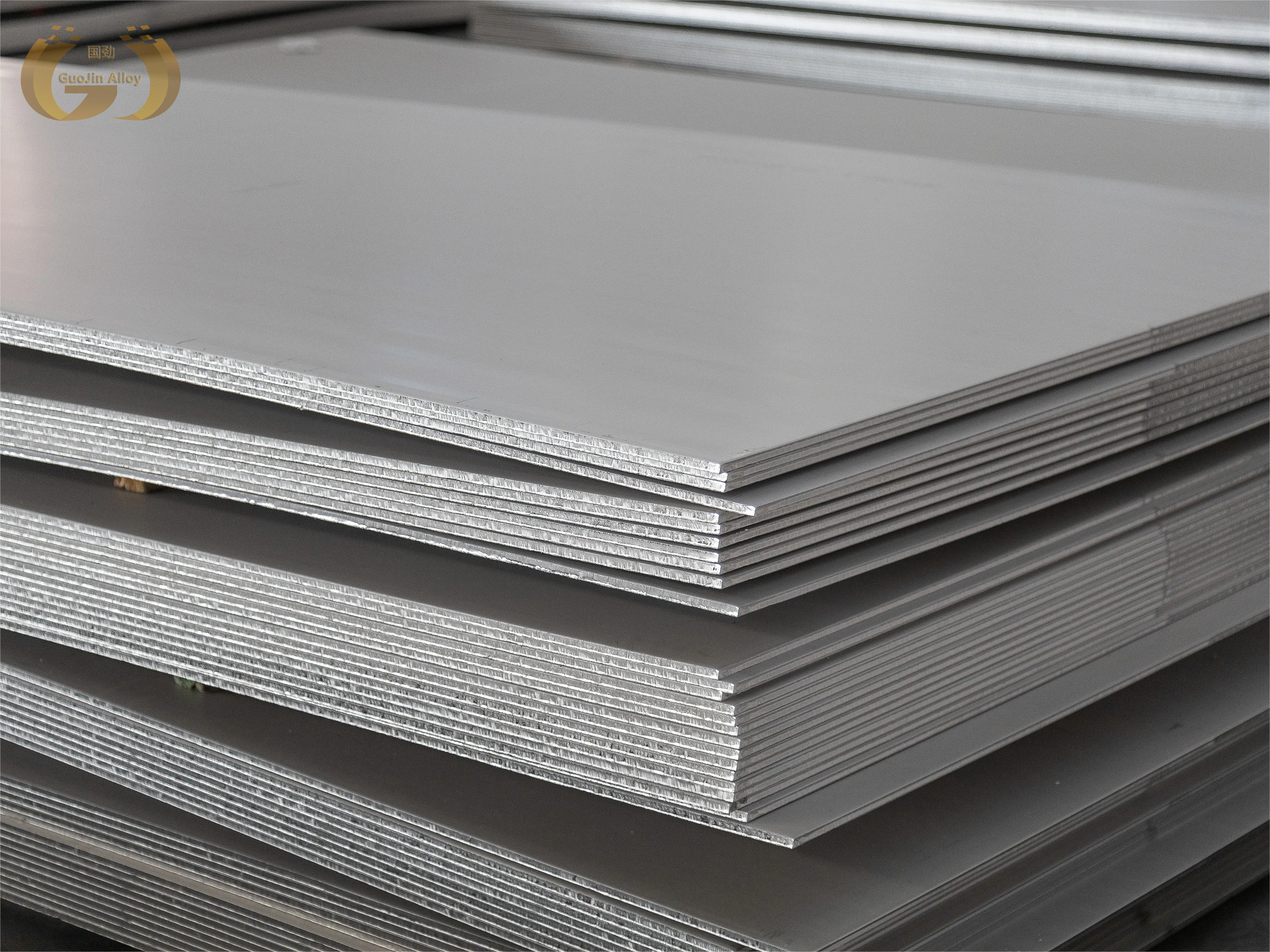

Plate/Sheet

Bar/Rod

Pipe/Tube

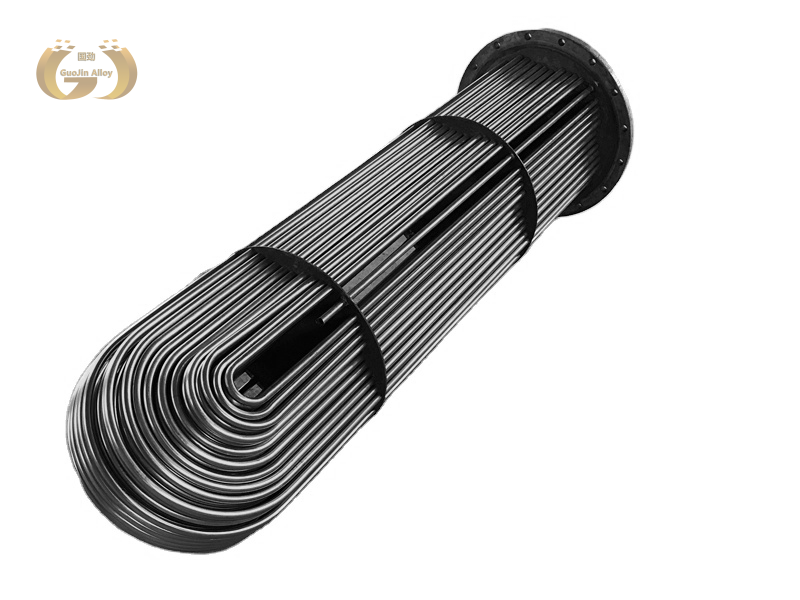

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

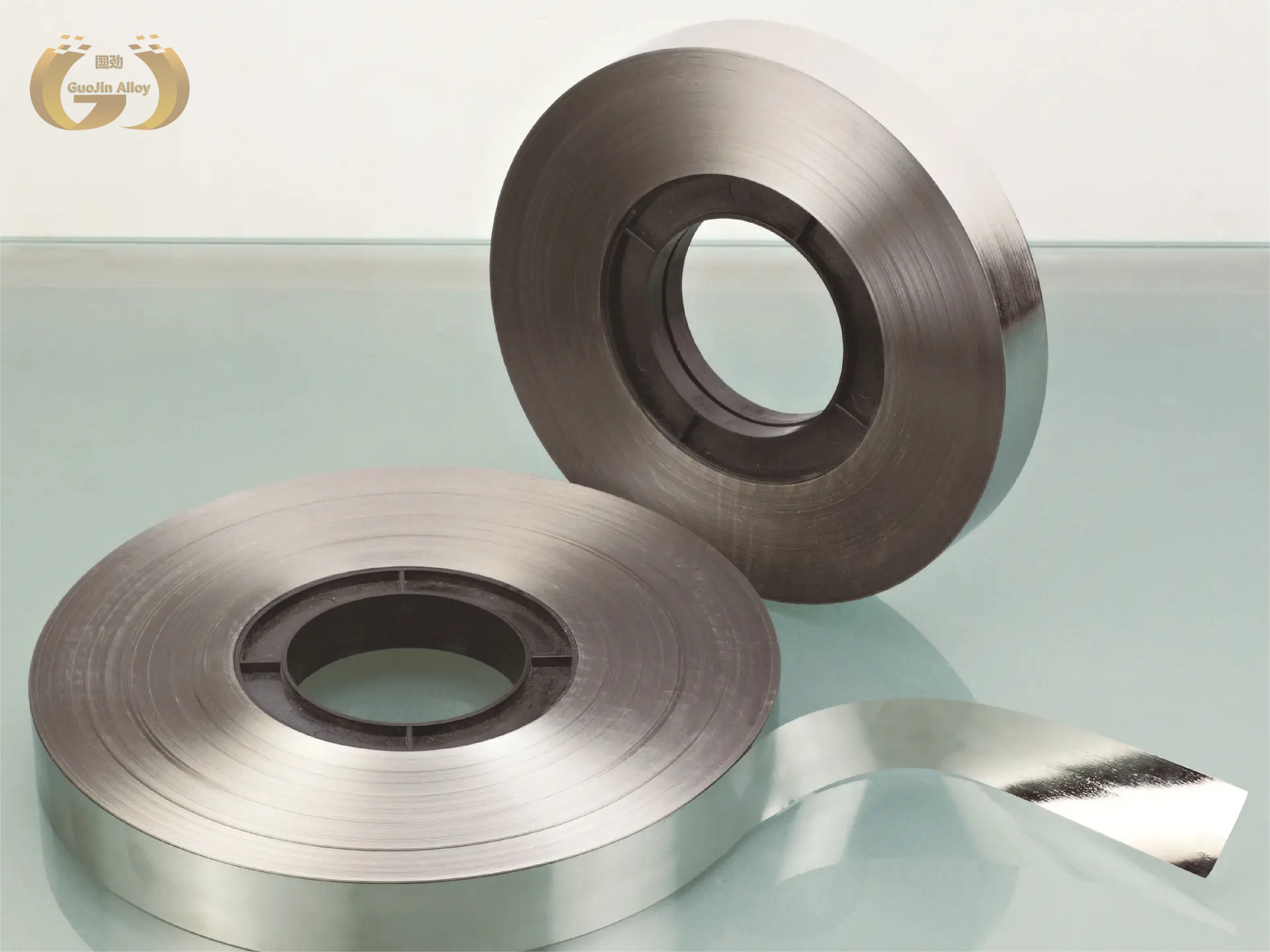

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

Introduction

Hastelloy X is a nickel-chromium-iron-molybdenum superalloy renowned for its exceptional high-temperature strength and oxidation resistance. Developed for applications requiring sustained performance in extreme environments, it exhibits remarkable resistance to oxidation and carburization in high-temperature atmospheres up to 2200°F (1200°C). Hastelloy X is widely utilized in gas turbine engines, aircraft engines, industrial furnaces, and other high-temperature applications where reliability and performance under harsh conditions are paramount. Its combination of mechanical strength, creep resistance, and thermal stability make it a preferred material for critical components subjected to extreme temperatures and corrosive environments.

Advantages of Hastelloy X

1. Exceptional high-temperature strength and oxidation resistance.

2. Versatile application in gas turbine and aircraft engines.

3. Superior resistance to oxidation and carburization.

4. Reliable performance in cyclic heating and cooling conditions.

5. Good creep resistance for prolonged high-temperature exposure.

6. Weldability facilitates ease of fabrication and assembly.

7. Maintains stability and performance at extreme temperatures.

8. Offers corrosion resistance in addition to high-temperature properties.

Hastelloy X application

Hastelloy X is extensively used in high-temperature applications such as gas and aircraft turbine engines, industrial furnaces, and aerospace components due to its exceptional strength and oxidation resistance. Additionally, it finds utility in heat treatment fixtures, petrochemical equipment, and nuclear reactor components, showcasing its versatility across various industries where reliability in extreme conditions is paramount.

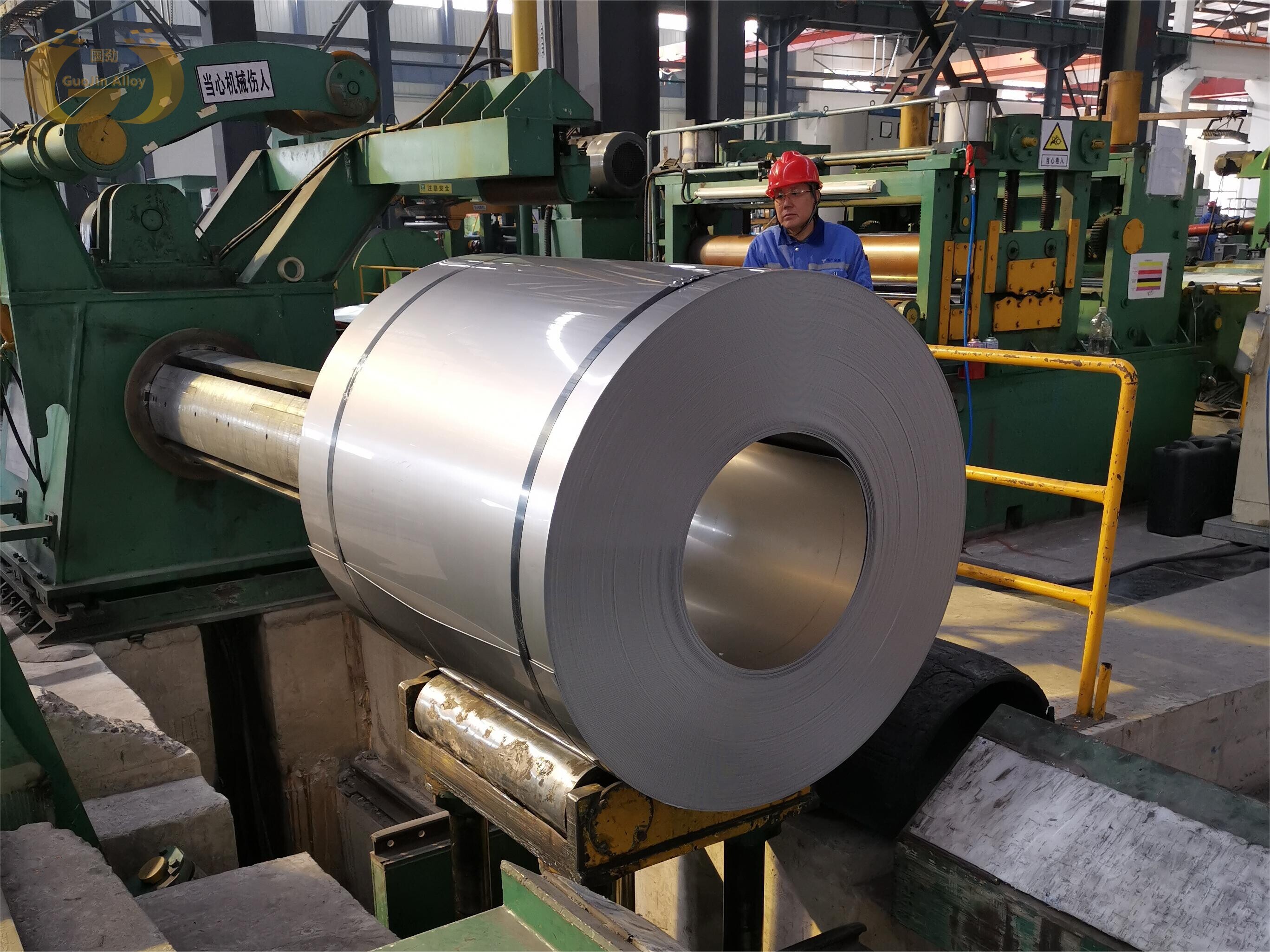

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.