Welcome to our company!

Equivalent grade:

● DIN W. Nr. 2.4360, 2.4361

◉ Available Products

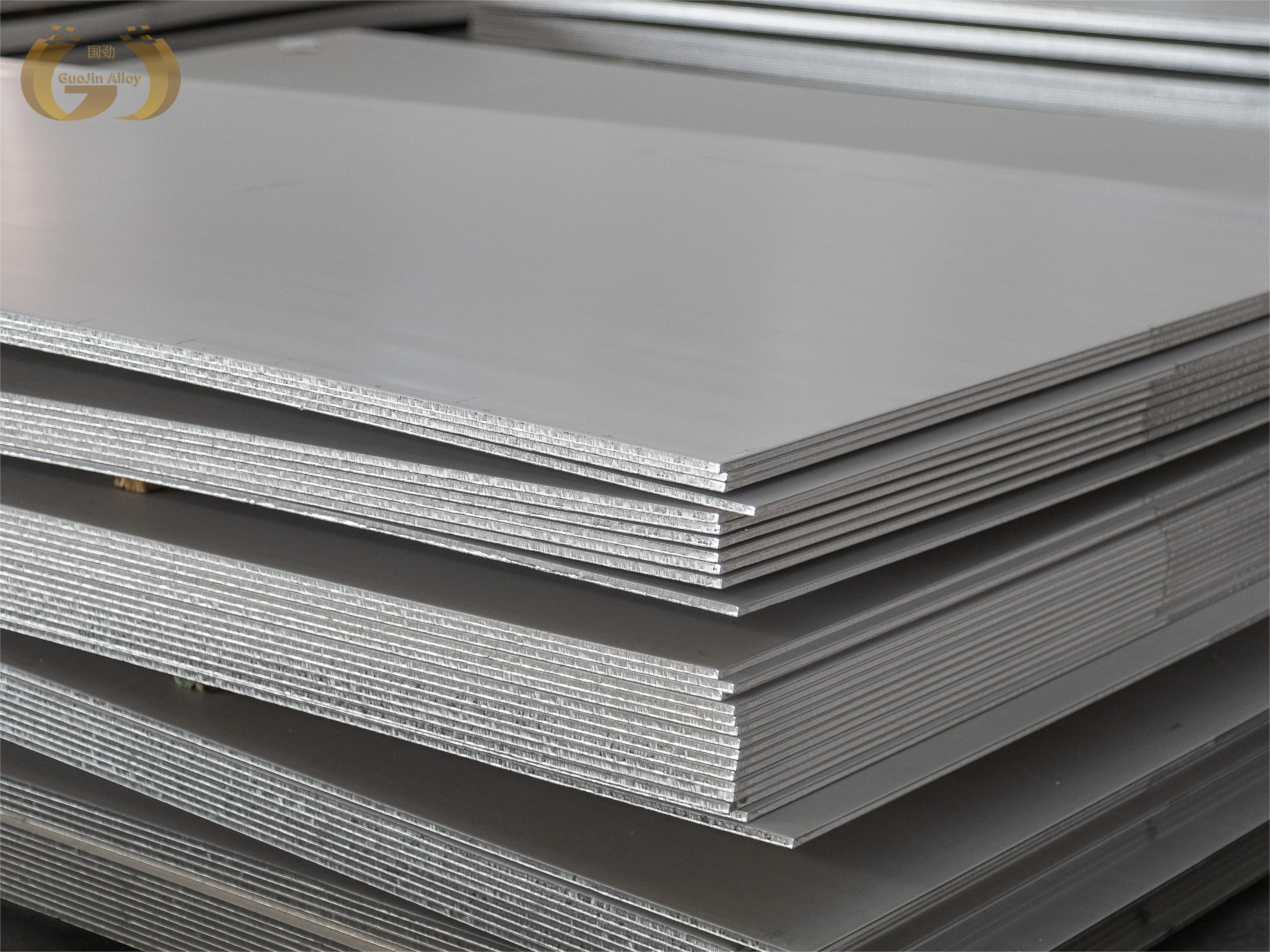

Plate/Sheet

Bar/Rod

Pipe/Tube

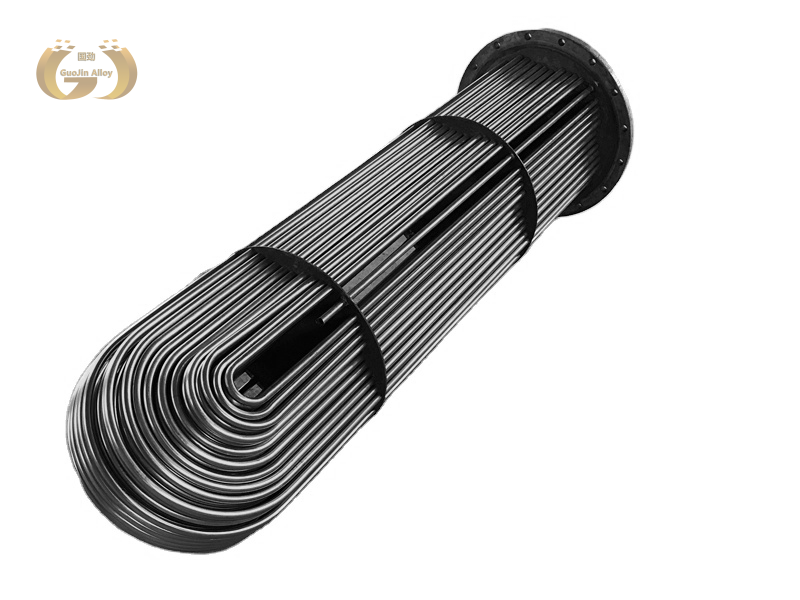

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

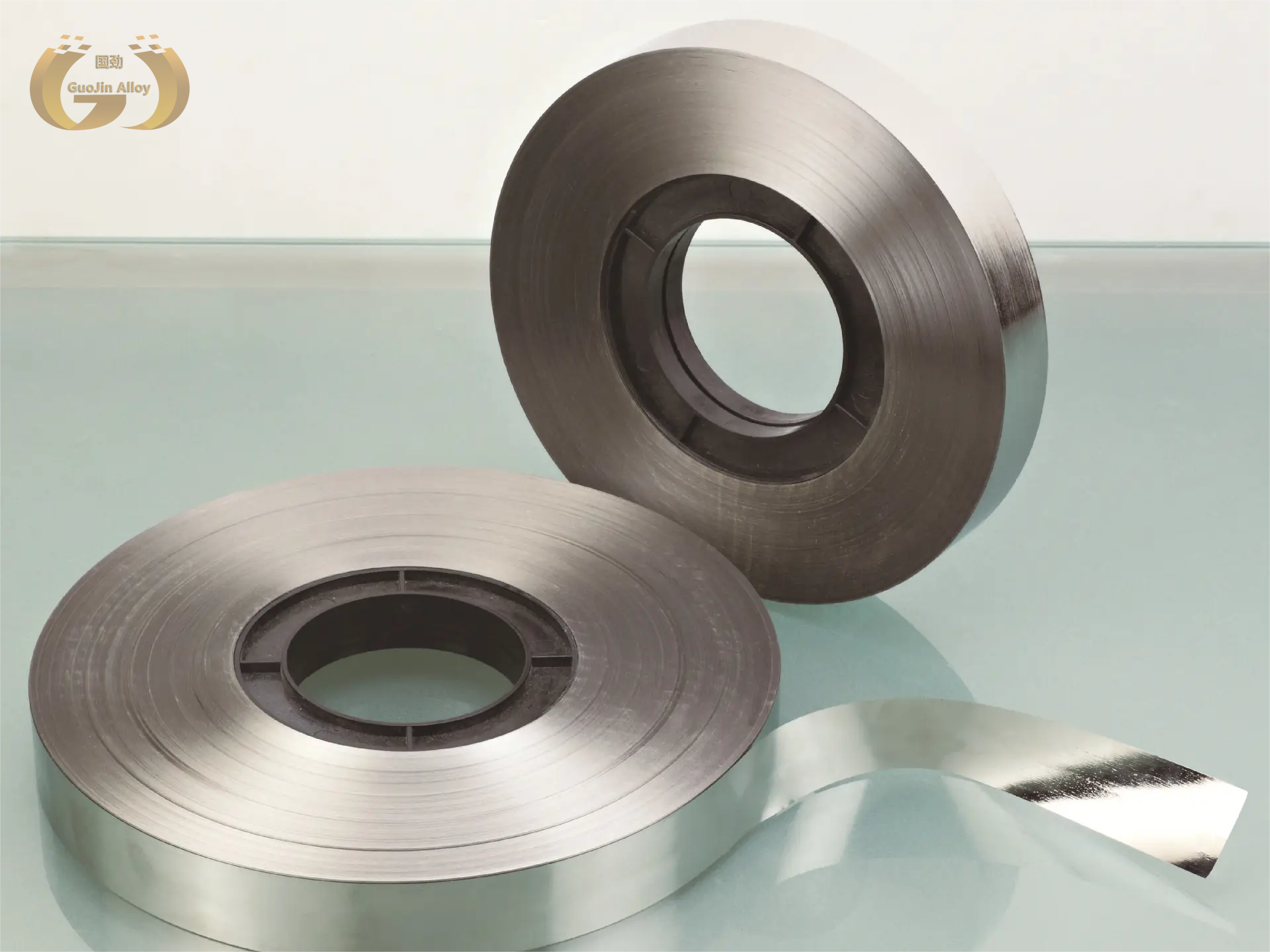

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

Monel 400 Material Properties

The chemical composition of the alloy is mainly composed of 30% Cu and 65% Ni with a small amount of Fe (1%-2%). Due to the difference in chemical composition, it can have a variety of alloy grades, but there is no significant difference in corrosion resistance between them. Monel400 alloy is more resistant to corrosion by reducing media than pure nickel, and more resistant to corrosion by oxidative media than pure copper. Monel400 is a deformable nickel-copper-based nickel-based alloy with good seawater corrosion resistance and chemical corrosion resistance, as well as chloride stress corrosion cracking resistance. This alloy is one of the few alloys that can be used in fluoride. It has good resistance to oxide stress fission corrosion in hydrofluoric acid and fluorine gas media, such as seawater and saltwater environments.

Advantage

1. Outstanding corrosion resistance in diverse environments.

2. High tensile strength and toughness at elevated temperatures.

3. Easy formability, machining, and welding due to ductility.

4. Low permeability to hydrogen gas for gas-tight applications.

5. Resistance to erosion and cavitation damage in high-velocity flows.

6. Retains mechanical properties across wide temperature ranges.

7. Long service life, reducing maintenance costs over time.

8. Versatile applications across marine, chemical, aerospace, and more.

Application areas of Monel 400 material

Monel 400 is mainly used in chemical and petrochemical and marine development fields. It can be used to manufacture various heat exchange equipment, boiler feed water heaters, petroleum and chemical pipelines, vessels, towers, tanks, valves, pumps, reactors, shafts, etc. Marine heat exchangers, desalination equipment, salt production equipment, marine and chemical processing equipment, propeller shafts and pumps, gasoline and water tanks, etc.

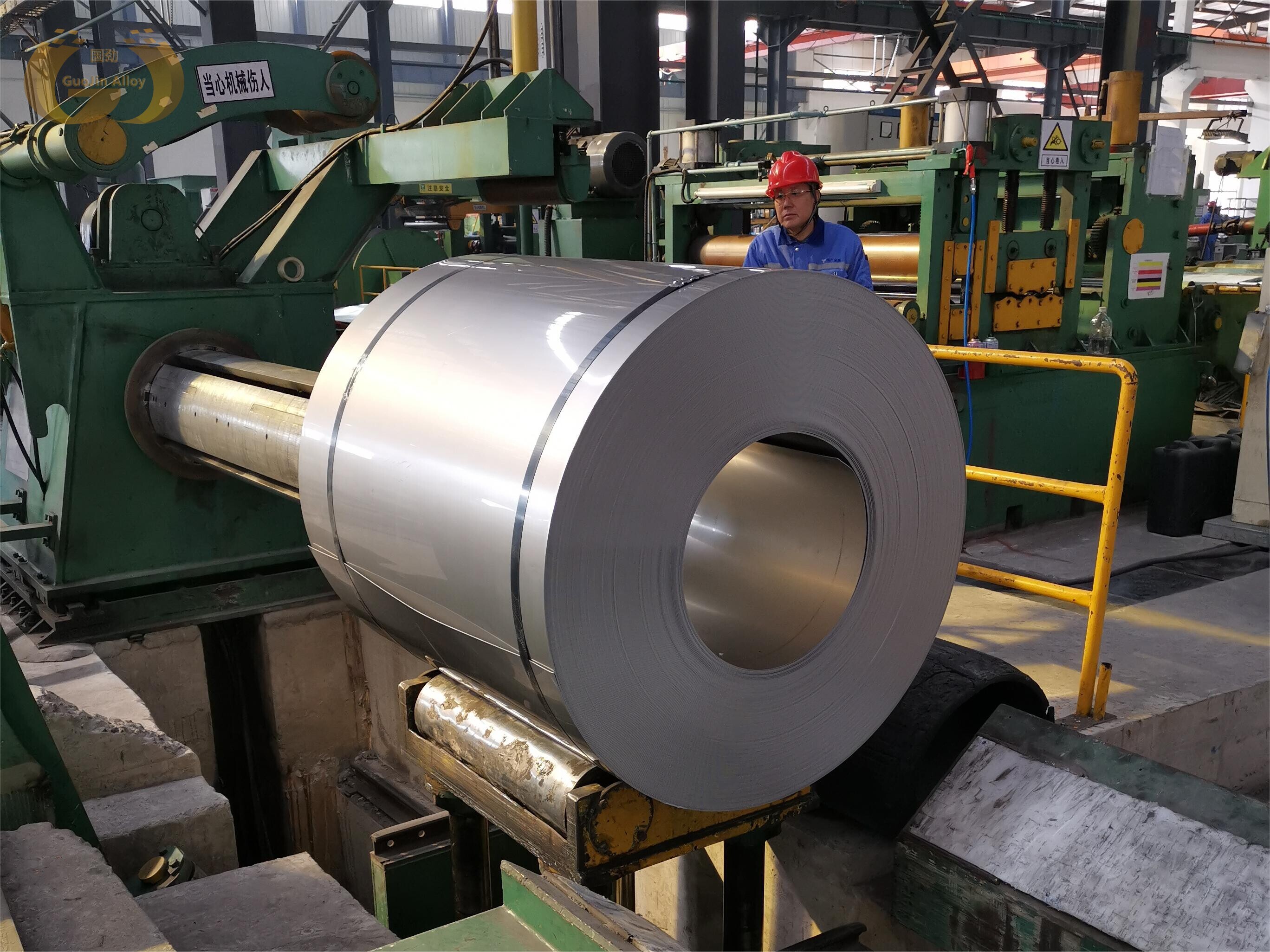

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.