Welcome to our company!

Equivalent grade:

● DIN W. Nr. 1.4501

● ASTM A182 F55

● EN 1.4501

● Z3CNDU25.07Az

◉ Available Products

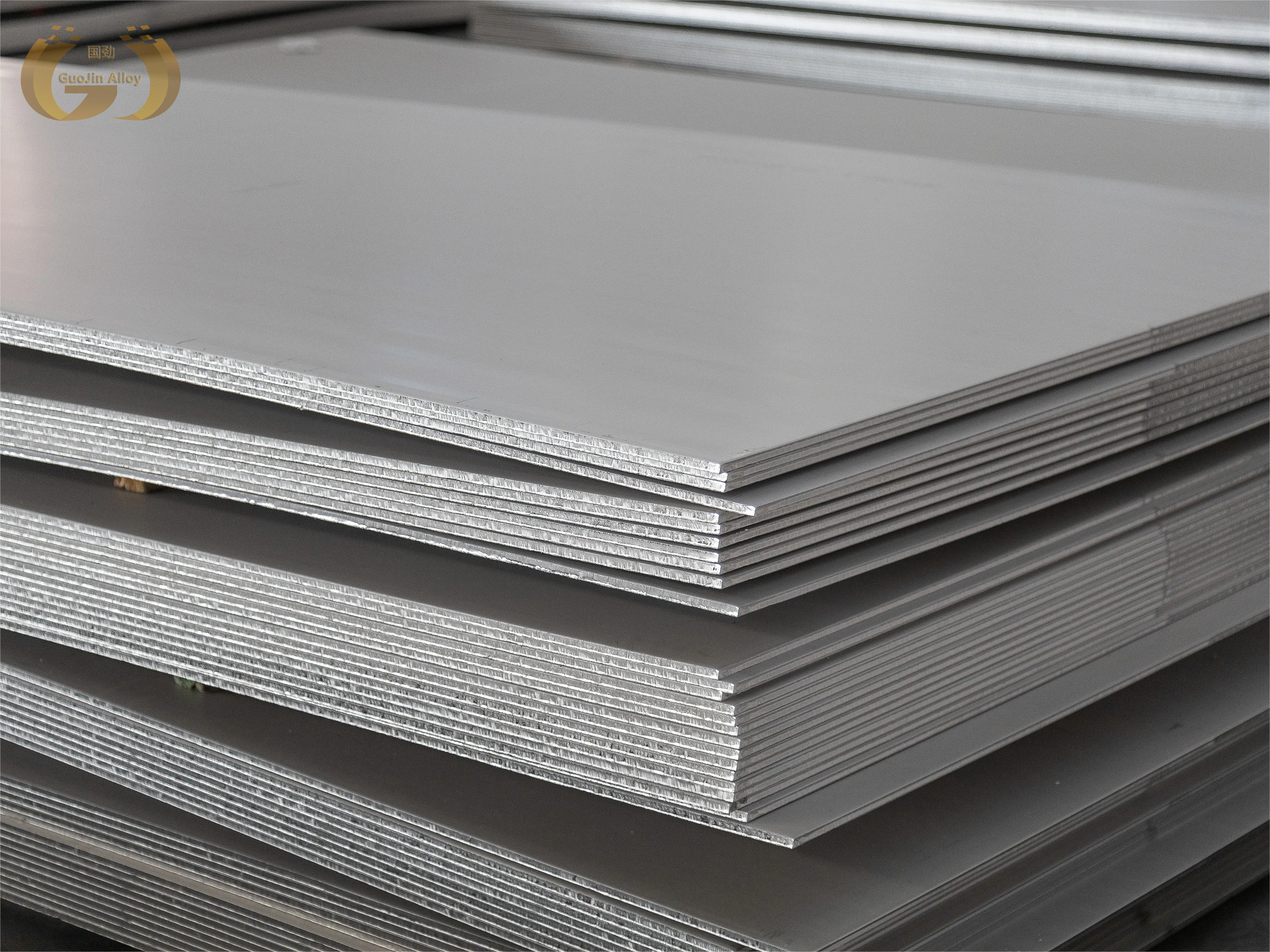

Plate/Sheet

Bar/Rod

Pipe/Tube

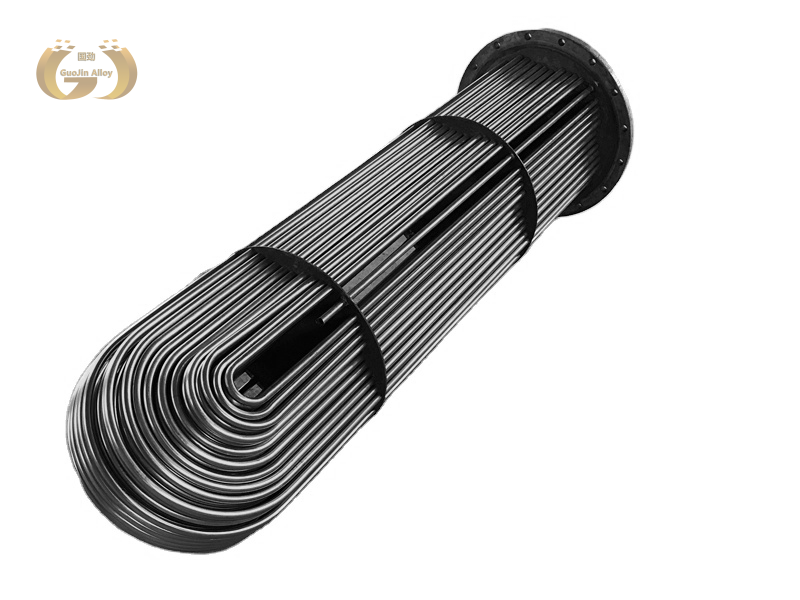

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

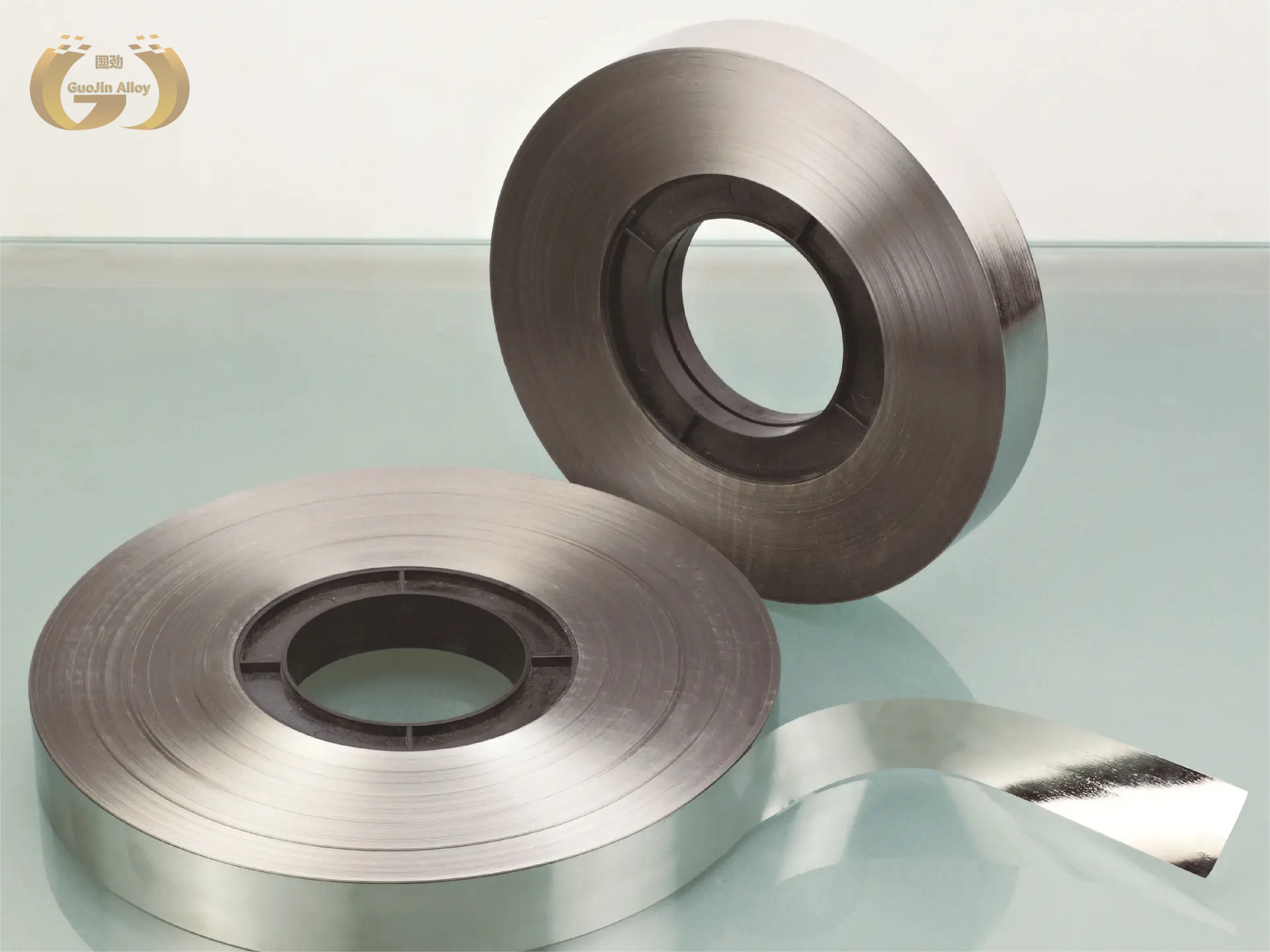

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

S32760 material properties

S32760 (F55), X2CrNiMoCuWN 25.7.4, German standard 1.4501, strong strength and corrosion resistance, mainly used in chemical processing, petrochemical and subsea equipment. It has strong resistance to chloride corrosion, high thermal conductivity and low thermal expansion coefficient. Higher chromium, molybdenum and nitrogen content, it has high resistance to pitting, crevice corrosion and general corrosion.

Alloy S32760 is a super duplex stainless steel supplied in the hot worked and solution annealed condition. As a super duplex stainless steel, it combines the desirable aspects of austenitic and ferritic steels. Higher chromium, molybdenum and nitrogen content results in a Pitting Resistance Equivalent Number (PREN) > 40, providing superior pitting and crevice corrosion capabilities over austenitic and duplex stainless steels in almost all corrosive media, and a critical pitting temperature Caution over 50°C. A version of the PREN formula also includes W as a positive effect on overall pitting resistance. It offers higher strength than austenitic and 22% Cr duplex stainless steels and is listed to NACE MR 0175 for sour service and ASME for pressure vessel applications

Advantage

1. Exceptional corrosion resistance in aggressive environments.

2. High strength and toughness for demanding applications.

3. Excellent resistance to pitting and crevice corrosion.

4. Superior resistance to chloride-induced stress corrosion cracking.

5. Good weldability and formability for versatile fabrication.

6. Enhanced resistance to erosion and wear for extended service life.

7. Cost-effective compared to higher alloyed stainless steels.

8. Low thermal expansion for dimensional stability in varying conditions.

9. Suitable for use in harsh chemical and marine environments.

10. Versatile for a wide range of industrial and offshore applications.

S32760 corresponding grade

1.4501

X2CrNiMoCuWN 25-7-4

Z3CND25.06Az

Norsok MDS D57

SAF32760

ASTM A276/A476

UNS S32760 (Super Duplex 32760)

ASME A182 F55

CD3MWCuN (casting grade)

25Cr

S32760 material application areas

S32760 is a kind of high strength and corrosion resistance, mainly used in chemical processing, petrochemical and subsea equipment. Application areas: Oil and gas industry equipment Offshore platforms, heat exchangers, underwater equipment, fire fighting equipment Chemical processing industry, vessel and pipeline industry Desalination plants, high pressure RO plants and submarine pipelines Mechanical components, high strength, anti-corrosion components.

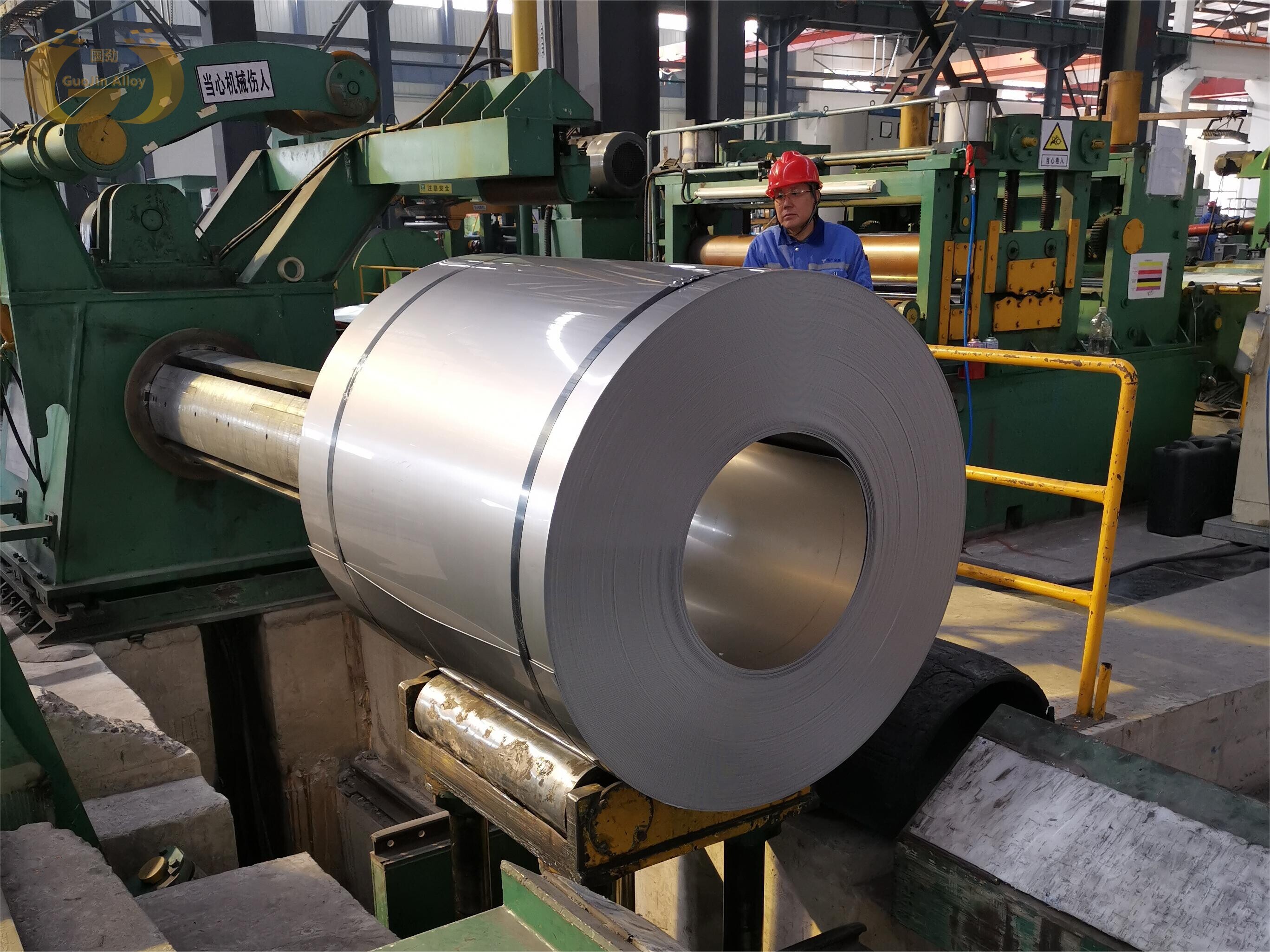

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.