Welcome to our company!

Equivalent grade:

● DIN W. Nr. 2.4663A

◉ Available Products

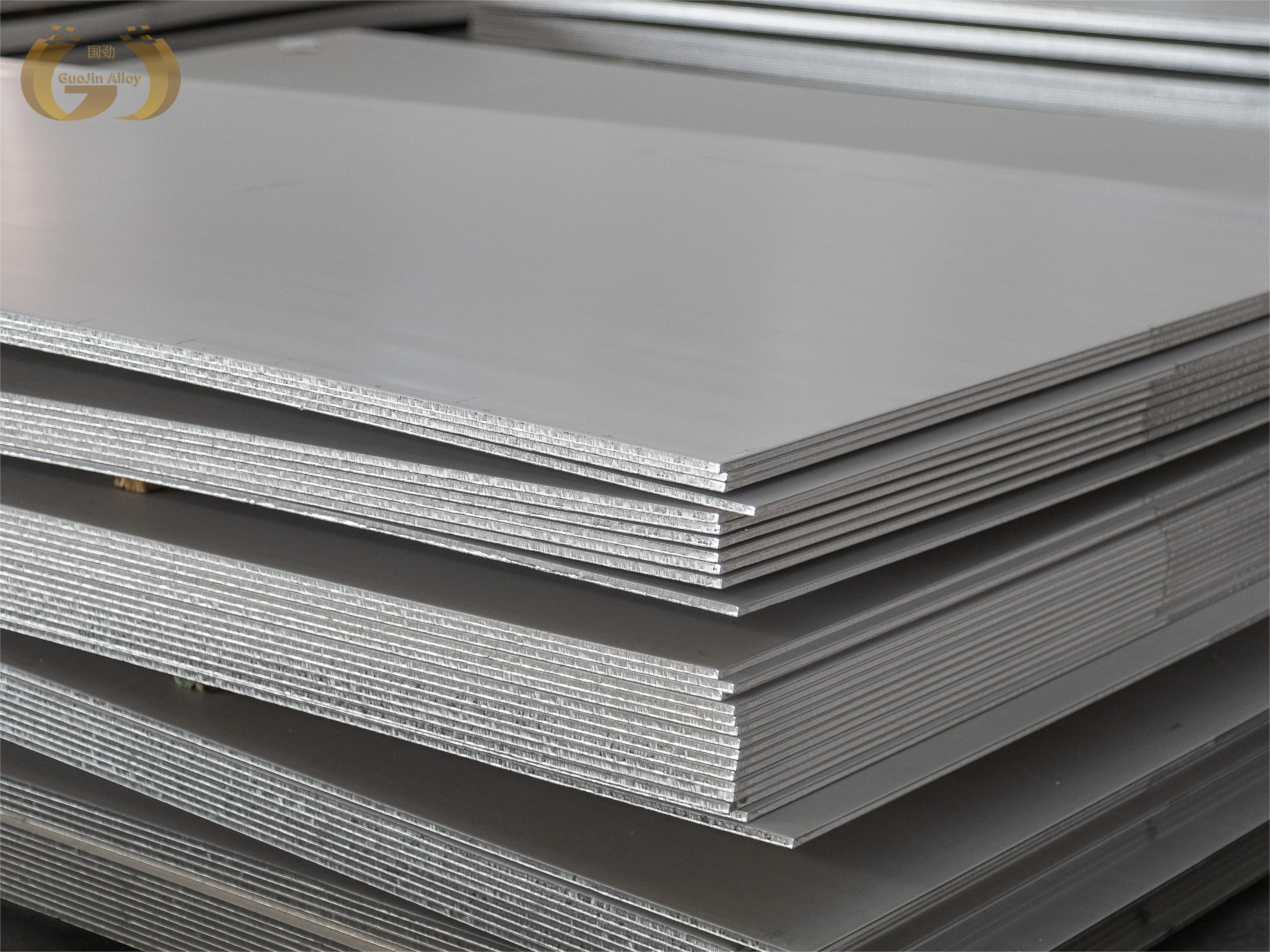

Plate/Sheet

Bar/Rod

Pipe/Tube

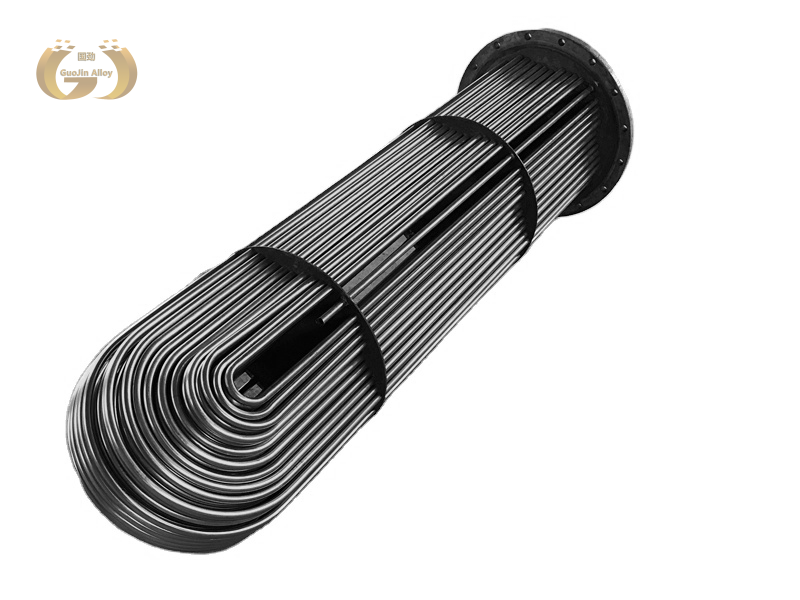

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

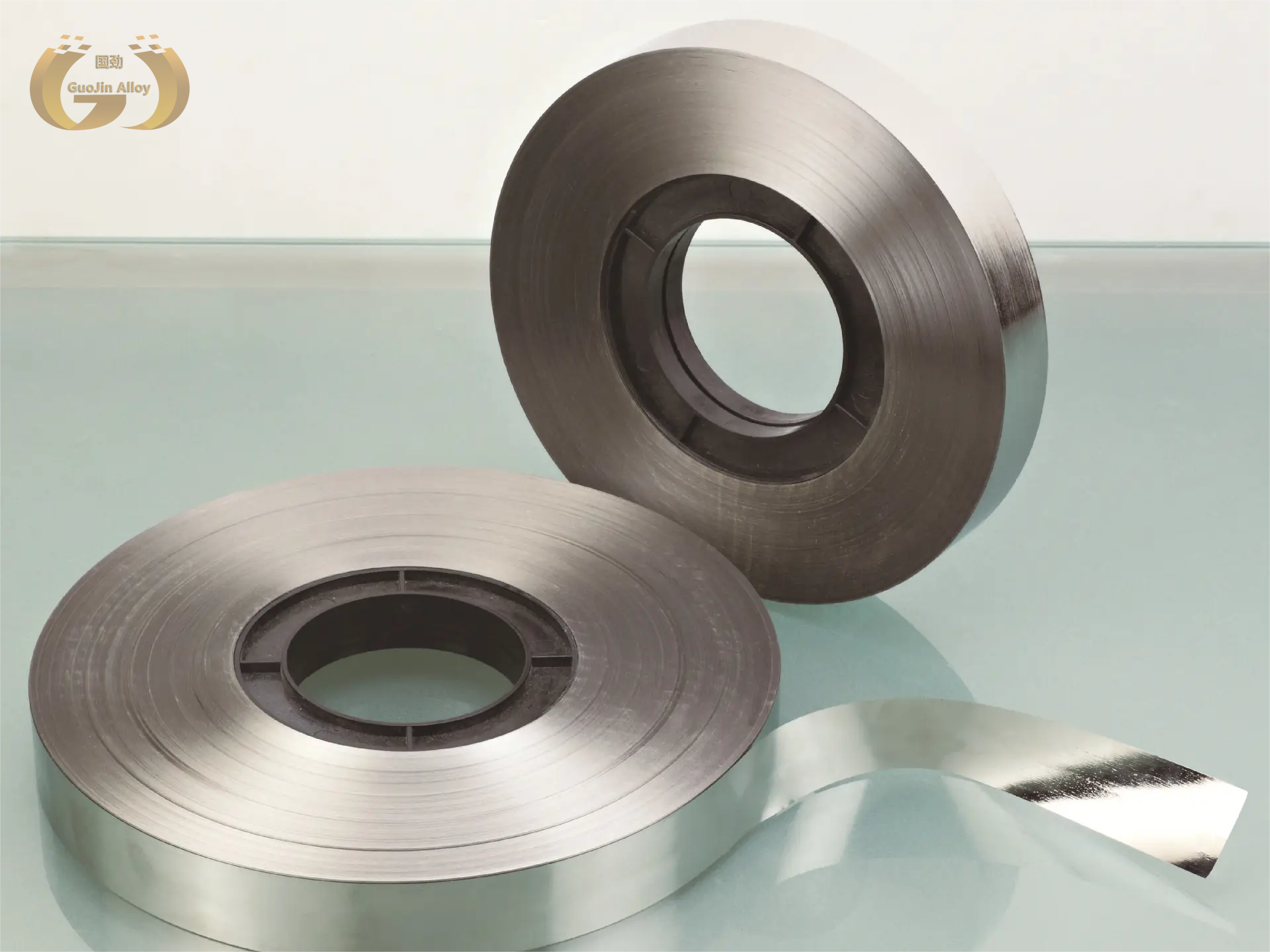

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

Inconel 617 Features

The alloy has excellent corrosion resistance and creep properties in hot corrosion areas such as sulfurized environments, especially in oxidizing and carbonizing environments up to 1100°C cycles. These corrosion resistances combined with excellent mechanical properties make this alloy particularly suitable for high temperature applications. Good short-term and long-term mechanical properties at high temperatures up to 1100°C. Excellent carburization resistance and good weldability at high temperatures up to 1100°C.

Inconel 617 is particularly suitable where high temperatures and particularly high mechanical stress are present. This alloy is recommended for operating temperatures up to 1000°C.

Advantage

1. High temperature strength and oxidation resistance.

2. Excellent resistance to carburization and sulfidation.

3. Good mechanical properties at elevated temperatures.

4. Resistance to chloride stress-corrosion cracking.

5. High creep rupture strength.

6. Suitable for high-temperature applications in aerospace, chemical processing, and power generation industries.

Typical application areas for Inconel617

1.Components of industrial and aviation gas turbines such as combustion cans, casings, turbine rings and other components exposed to high temperatures,

2.Air heaters, muffles and radiant pavilions

3.High temperature heat exchangers, valves and springs,

4.High temperature gas-cooled nuclear reactors, such as nuclear reactor high temperature components - helium/helium medium heat exchanger

5.Chemical equipment, spiral pipes and pipes in the petrochemical industry, retorts and components in heat treatment furnaces, aircraft fuselage components, nuclear reactors.

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.