Welcome to our company!

Equivalent grade:

● DIN W. Nr. 2.4668

◉ Available Products

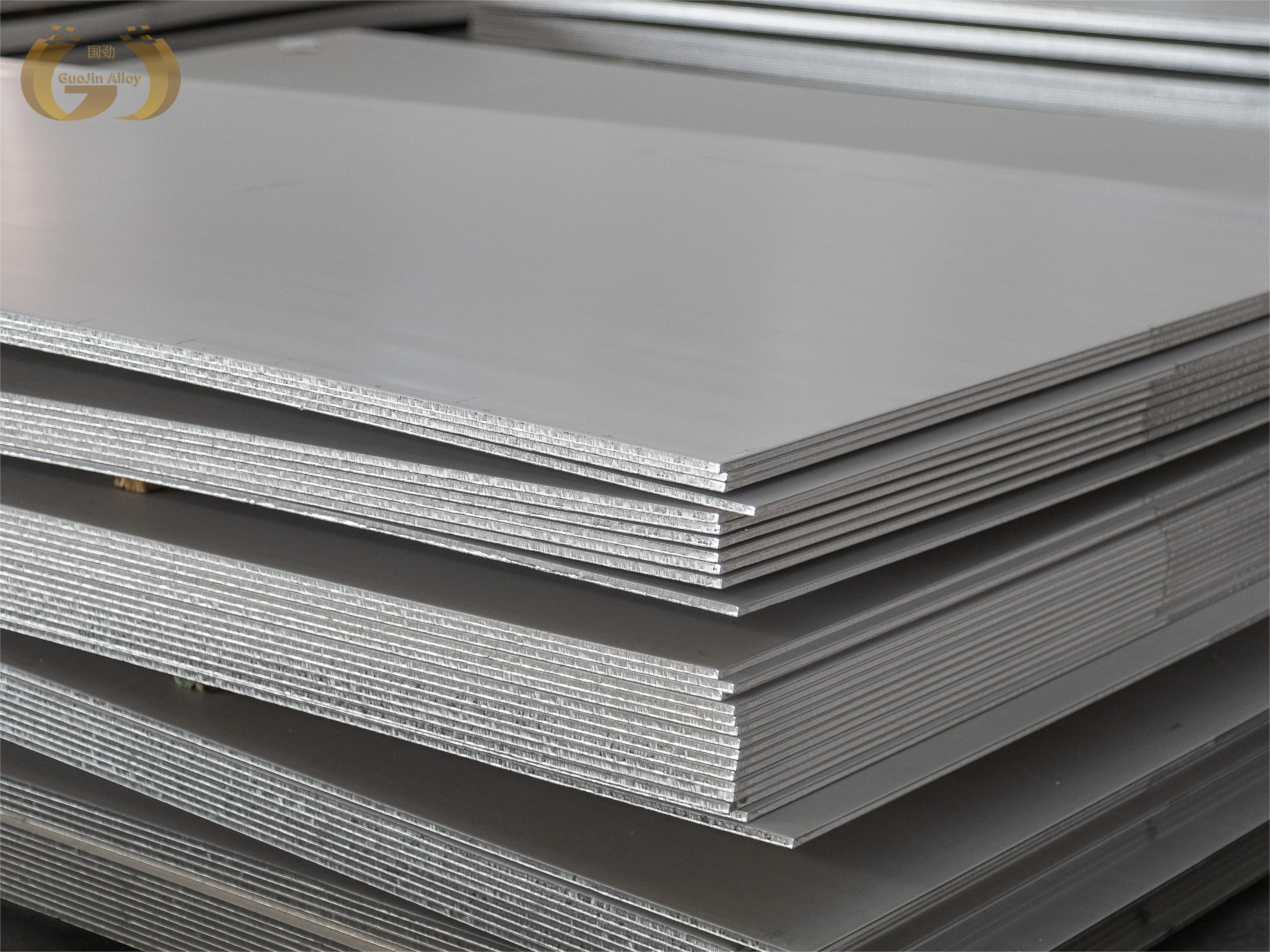

Plate/Sheet

Bar/Rod

Pipe/Tube

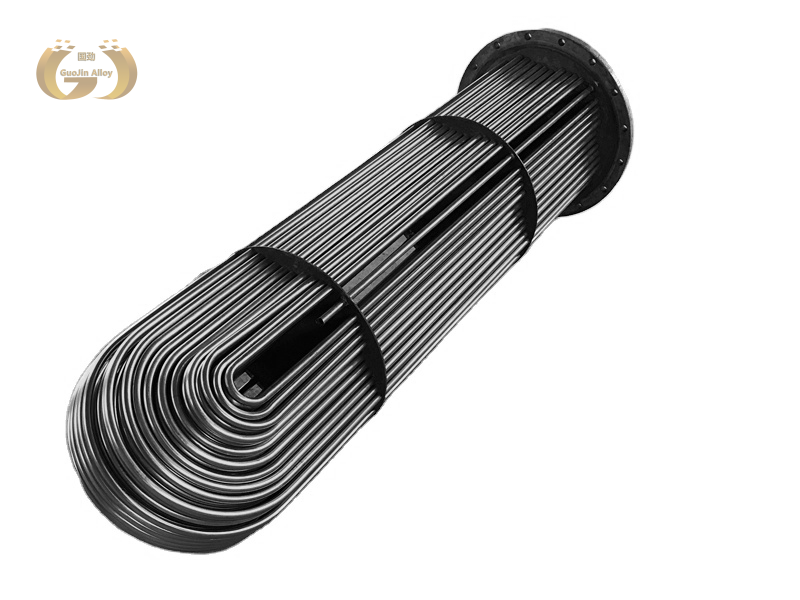

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

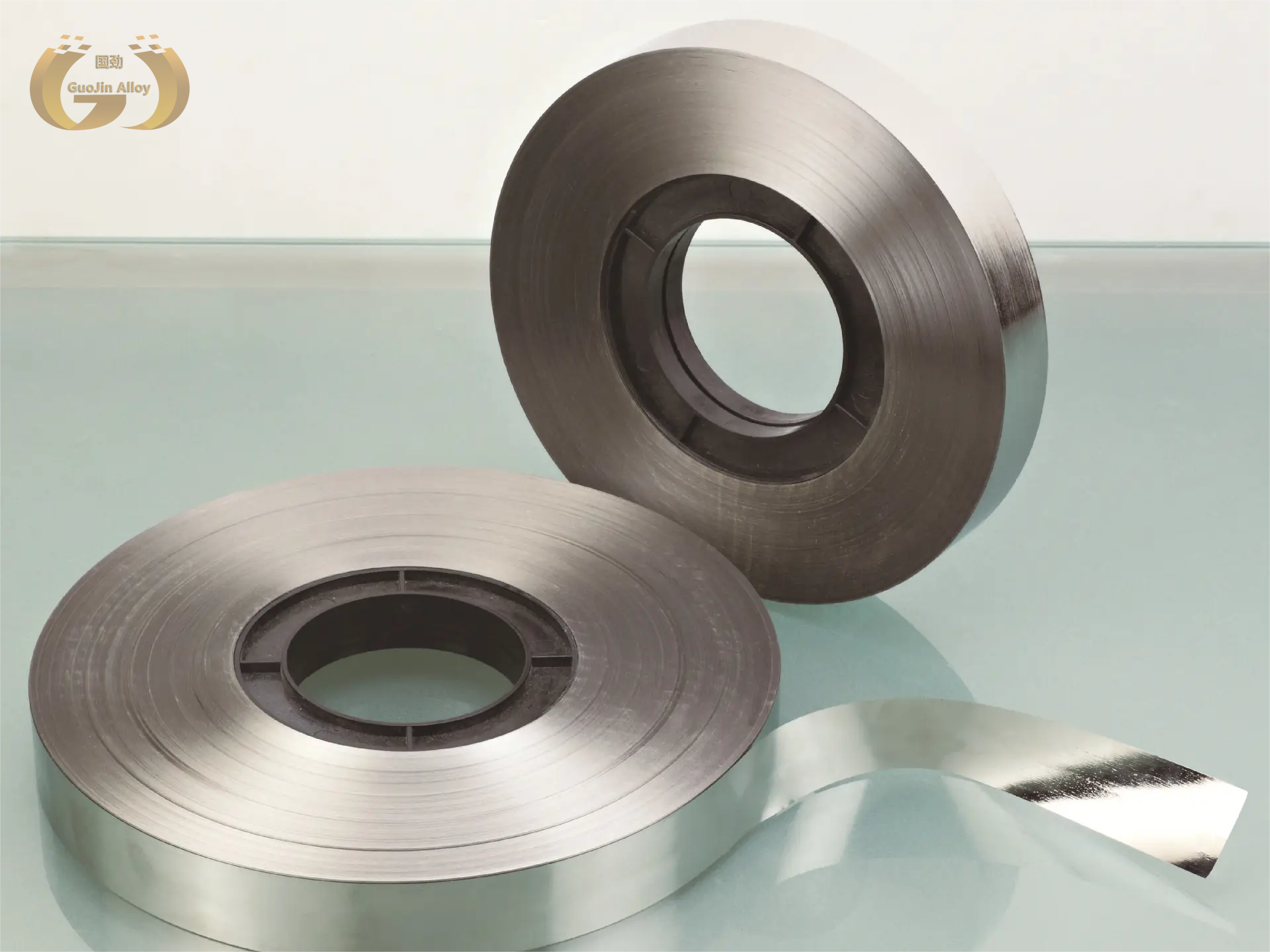

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

Inconel 718 Features

Inconel718 alloy is a precipitation hardening nickel-chromium-iron alloy containing niobium and molybdenum. It has high strength, good toughness and corrosion resistance in high and low temperature environments below 650 °C. The state may be solution treated or precipitation hardened.

Advantages

1. Ease of processing

2. High tensile strength, fatigue strength, creep strength and rupture strength at 700℃

3. High oxidation resistance at 1000℃

4. It has stable chemical properties at low temperature

5. Good welding performance

Inconel 718 product application areas

Due to its high temperature strength at 700°C, excellent corrosion resistance and easy processability, it can be widely used in various high-demand occasions.

1. Steam turbine

2. Liquid fuel rocket

3. Cryogenic engineering

4. Acid environment

5. Nuclear Engineering

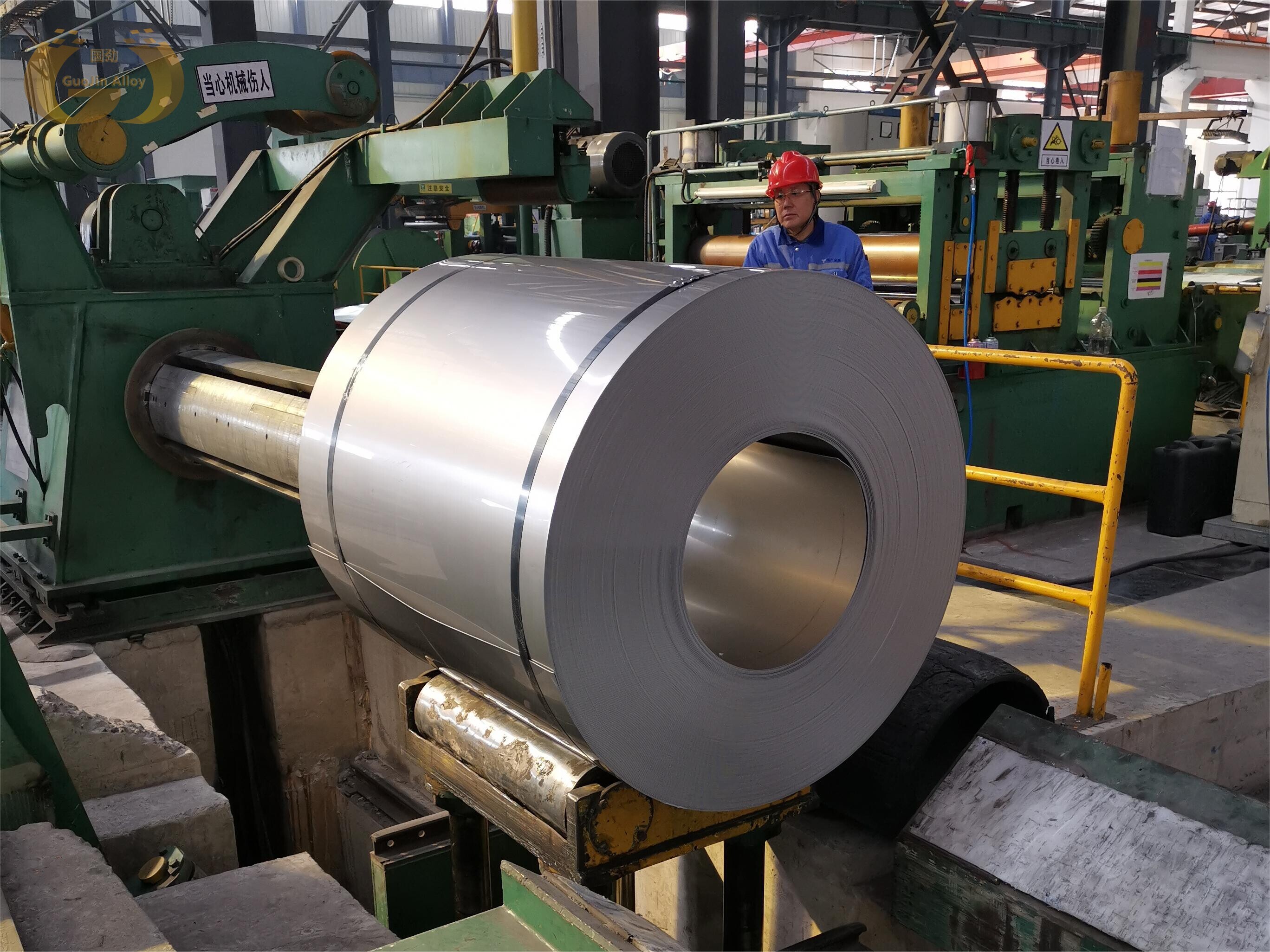

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.