Welcome to our company!

Equivalent grade:

● Alloy 925

● DIN EN 2.4856

◉ Available Products

Plate/Sheet

Bar/Rod

Pipe/Tube

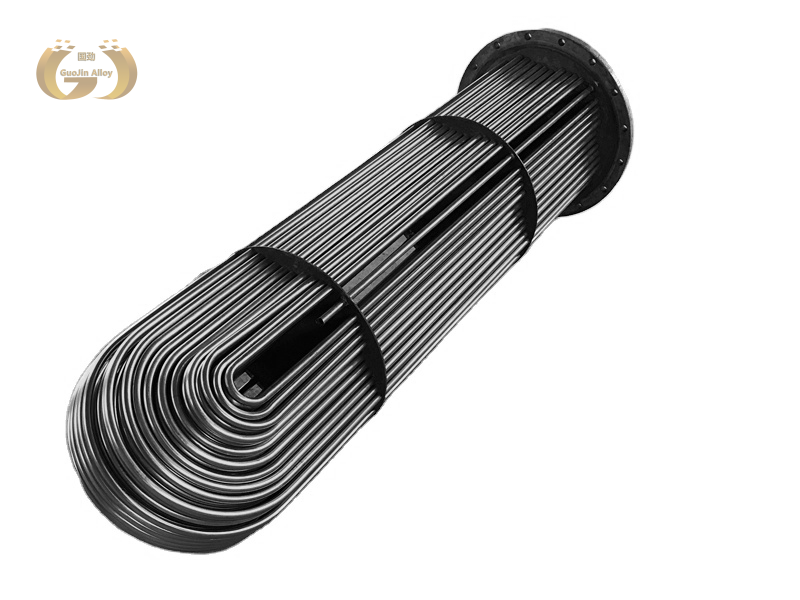

U bend pipe

Coil tube

Pipe fittings (Flange,Tee, Elbow,Reducer...)

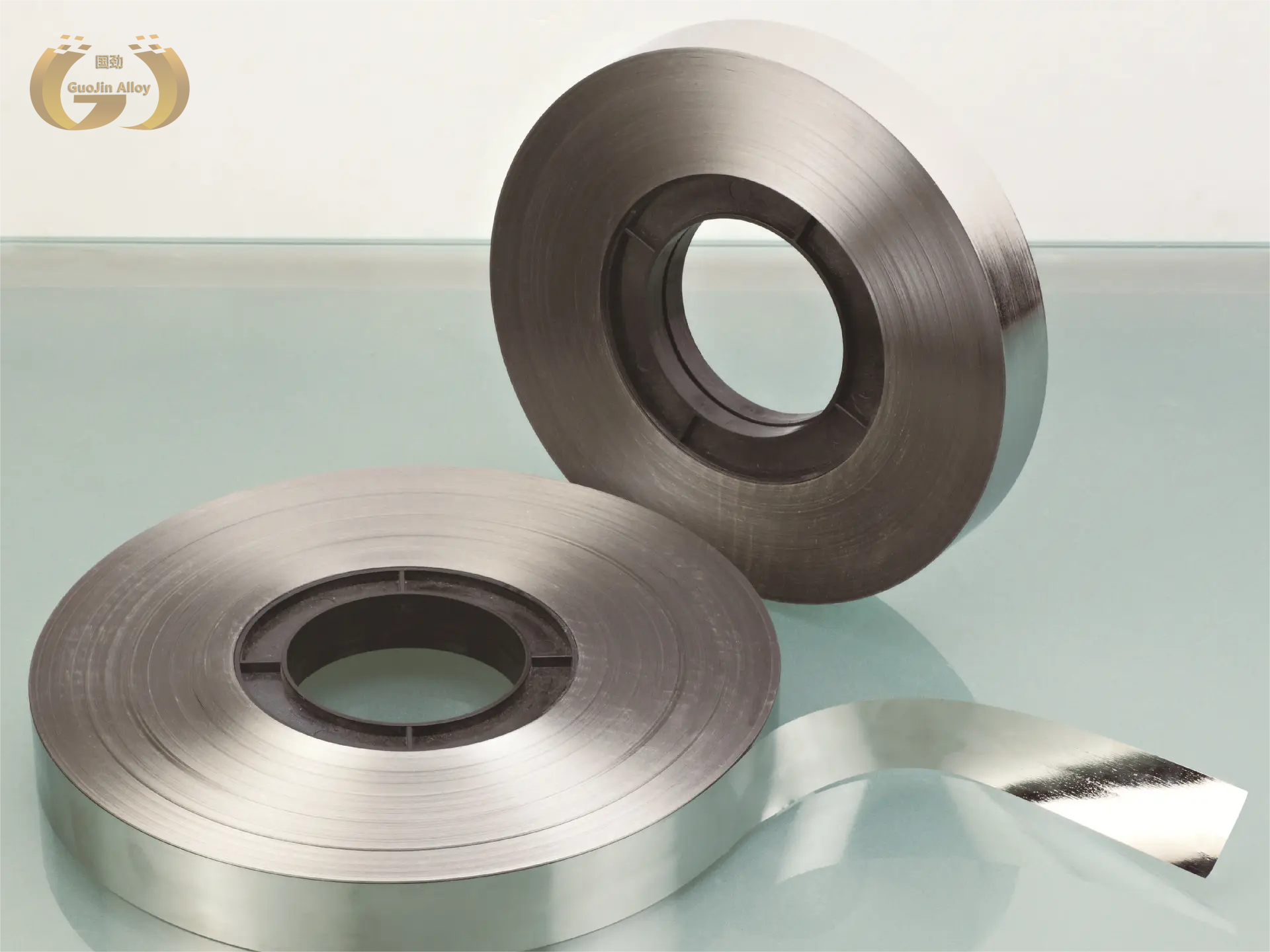

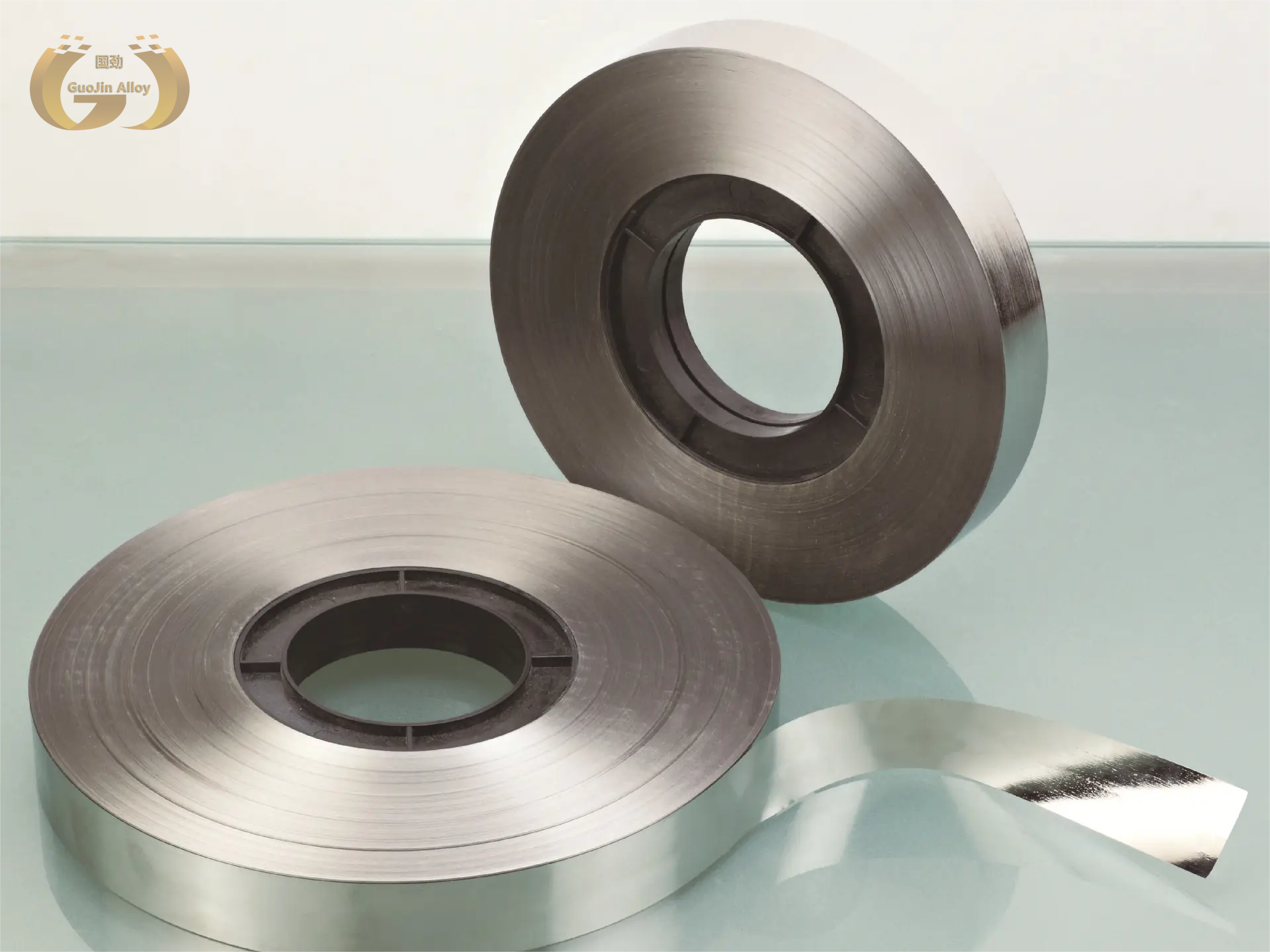

Strip

Fittings

Wire

Forgings

Fastener

Castings

Customization

◉ Product Details

Chemical composition

Physical properties

Incoloy 925 material properties

Incoloy 925 is a nickel-iron-chromium alloy with additions of molybdenum, copper, titanium, and aluminum. It offers excellent corrosion resistance in a wide range of environments, including sulfide and chloride-containing media. In addition to its corrosion resistance, Incoloy 925 exhibits high strength, good fatigue resistance, and exceptional toughness at both room and elevated temperatures. Its combination of properties makes it suitable for various applications in industries such as oil and gas, chemical processing, and marine engineering, where resistance to corrosion and mechanical integrity are critical requirements.

Advantage

1. High corrosion resistance in diverse environments.

2. Excellent mechanical strength for demanding industrial applications.

3. Superior fatigue resistance, ensuring long-term reliability.

4. Good toughness at both room and elevated temperatures.

5. Versatile material suitable for various industries and applications.

6. Enhanced resistance to sulfide and chloride-containing media.

7. Long-term durability in harsh operating conditions.

8. Reliable performance in oil and gas, chemical processing, marine engineering.

Incoloy 925 material application areas

1. Oil and Gas Industry: Incoloy 925 is utilized in downhole and surface equipment in oil and gas exploration and production due to its excellent corrosion resistance and high strength.

2. Chemical Processing: It finds applications in chemical processing plants for components exposed to corrosive chemicals and high temperatures.

3. Marine Engineering: Incoloy 925 is used in marine environments for its resistance to corrosion from seawater and marine atmospheres.

4. Aerospace Industry: It is employed in aircraft components exposed to high temperatures and corrosive environments.

5. Power Generation: Incoloy 925 finds applications in power generation facilities for components subjected to high temperatures and corrosive gases.

6. Industrial Applications: It is used in various industrial applications requiring resistance to corrosion and high strength.

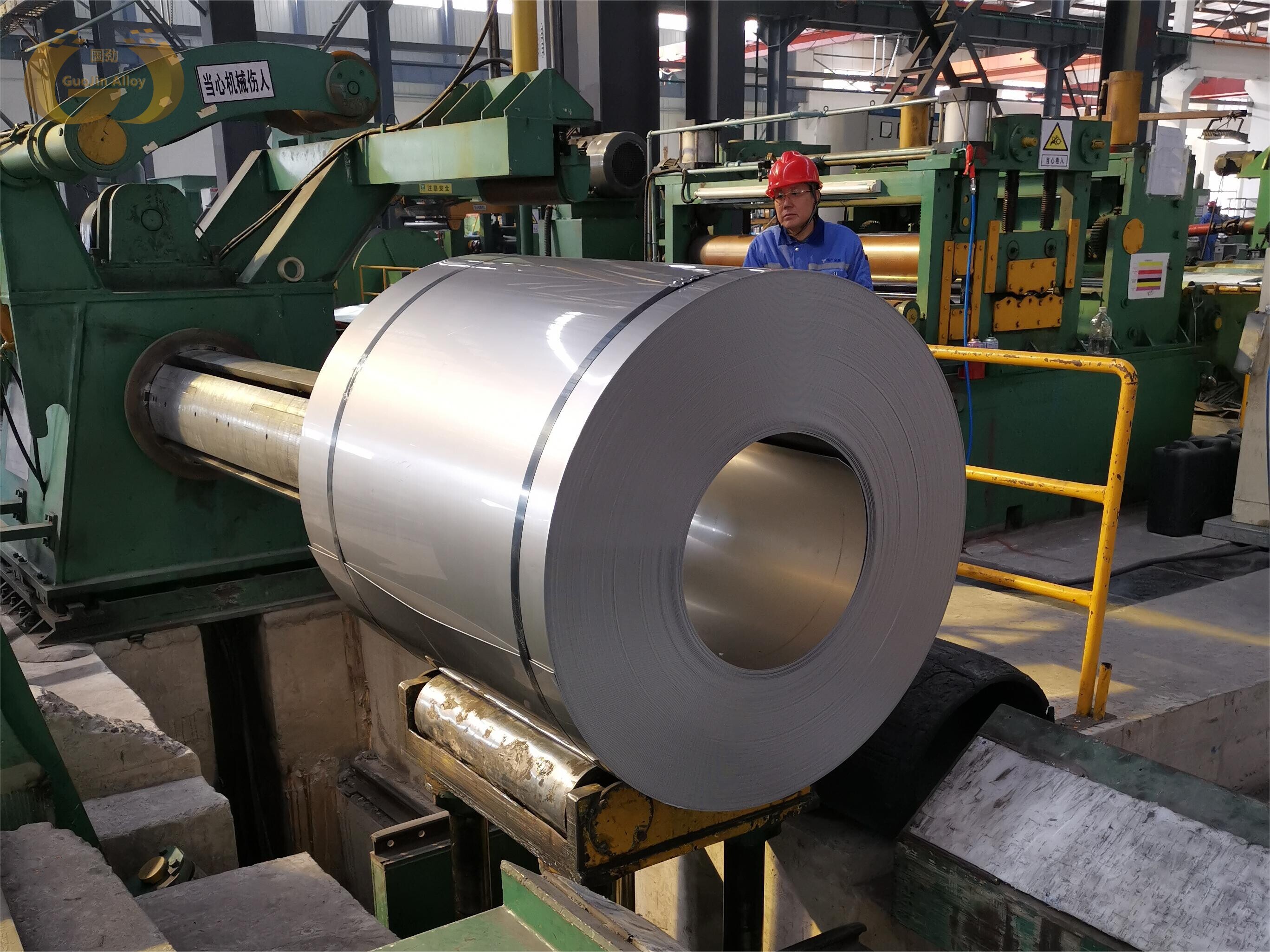

◉ Factory Tour

◉ Customer Visit

◉ Online Consultation

Reliable detection!

We accept formal third-party testing institutions for testing, we can also send samples to you free of charge, customer satisfaction shopping experience is always our pursuit

Interested in?

◉ Related Suggestion

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.